Method for preparing organosilicone stripping agent by emulsion polymerizing

A technology of emulsion polymerization and silicone, which is applied in the field of preparing silicone release agents, can solve the problems of high requirements for industrial production equipment, and achieve the effects of low production cost, good emulsion uniformity, and reduced operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

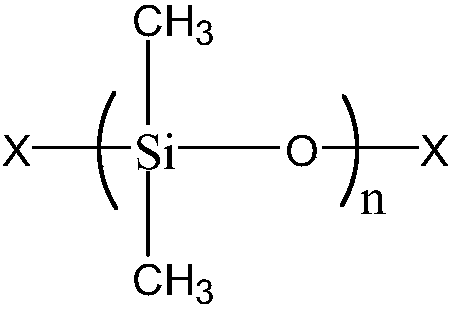

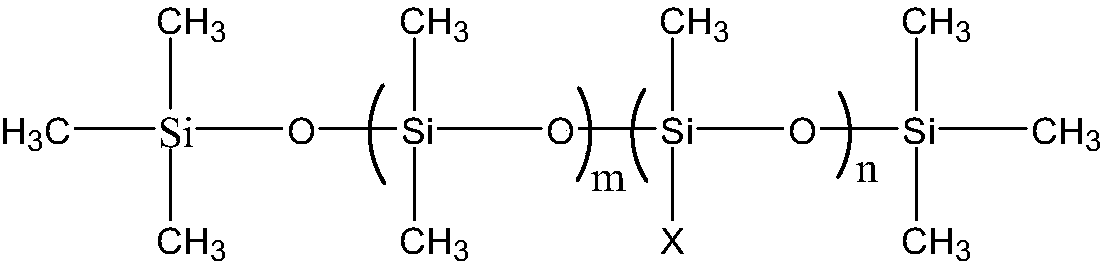

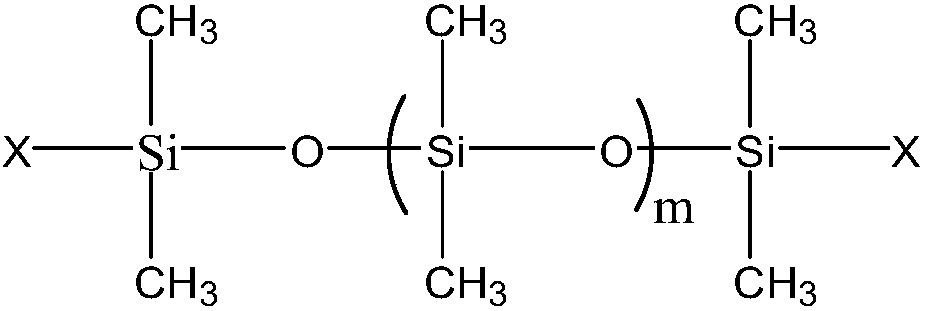

Method used

Image

Examples

Embodiment 1

[0030] Add 80g of DMC, 130g of deionized water, 10g of dodecylbenzenesulfonic acid, and 2g of low-viscosity hydroxyl silicone oil with a degree of polymerization of 6 into the reactor, raise the temperature to 40°C and stir for 1 hour to prepare a prepolymer emulsion, and continue to add 5g of side chains Polyether silicone oil, 12g sodium dodecylbenzene sulfonate, 2g silane coupling agent KH550, stirred and heated to 85°C for polymerization for 4 hours, then added 5% sodium hydroxide solution to neutralize to neutral, and the emulsion type silicone desulfurizer was obtained. mold agent.

[0031] The technical indicators of the product are as follows:

[0032] Appearance: white with fluorescent blue emulsion; pH value: 7; stability: no separation after centrifugation at 4000r / min for 15min; active ingredient: 45%.

Embodiment 2

[0034] Add 80g of DMC, 130g of deionized water, 10g of hexadecylbenzenesulfonic acid, and 2g of hydroxyl silicone oil with a degree of polymerization of 18 into the reactor, raise the temperature to 40°C and stir for 1 hour to prepare a prepolymer emulsion, and continue to add 5g of terminal polyether Silicone oil, 16g sodium hexadecylbenzenesulfonate, 2g silane coupling agent KH550 as structure control agent, stir and heat up to 95°C for catalytic polymerization, polymerization time is 5h, after the polymerization is completed, directly add 5% sodium hydroxide solution for neutralization , That is, an emulsion-type silicone release agent.

Embodiment 3

[0036] Add 80g of D4, 130g of deionized water, 10g of dodecylbenzenesulfonic acid, and 10g of low-viscosity hydroxyl silicone oil with a viscosity of 25cs into the reaction kettle, raise the temperature to 40-50°C and stir for 1 hour to prepare a prepolymer emulsion, and continue to add 10g of side Chain polyether silicone oil, 12g sodium dodecylbenzene sulfonate, 5g silane coupling agent KH560, stir and raise the temperature to 90°C for catalytic polymerization, the polymerization time is 5h, after the polymerization is completed, directly add ammonia water to neutralize to neutral, and then the emulsion type organic Silicone release agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com