High-efficiency energy-saving vortex spray-condensation type electric bag composite dust collector

An electric bag composite, high-efficiency and energy-saving technology, applied in the direction of combination devices, chemical instruments and methods, separation methods, etc., can solve the problems of rising emissions, and achieve the effects of energy saving, high degree of automation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

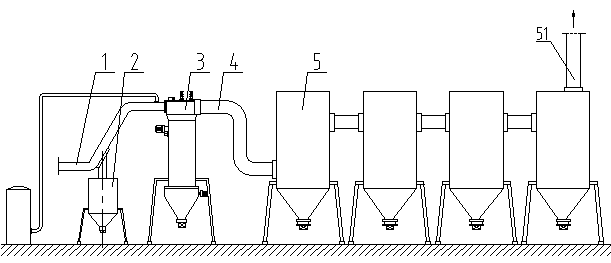

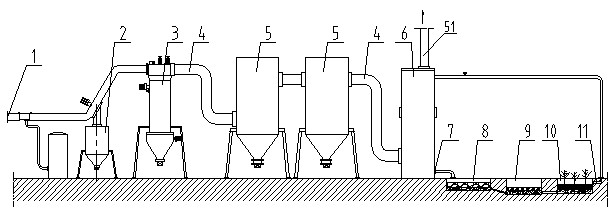

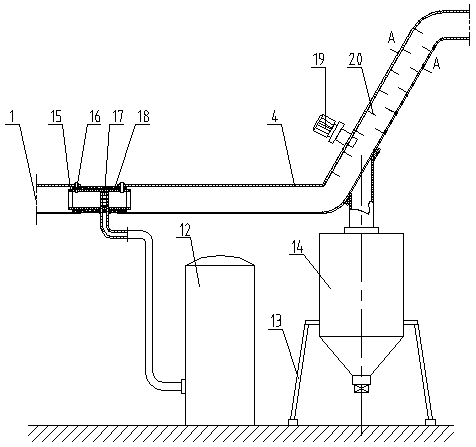

[0035] A thermal power plant in Nanning City, in November 2016, adopted the high-efficiency and energy-saving spiral spray condensing electric bag composite dust collector of the present invention, see the attached figure 1 and Figure 3-8 As shown, the dust collector of the present invention includes a dust inlet 1, a first-stage dust collector 2, a second-stage dust collector 3, an exhaust pipe 4, a third-stage dust collector 5, a fourth-stage water spray dust collector 6, Sewage outlet 7, primary settling tank 8, secondary settling tank 9, tertiary settling tank 10, purified water outlet 11, limestone addition 12, support frame 13, primary dust collection tank 14, connecting pipe 15, connecting bolt 16, Lime powder inlet 17, insulation layer 18, vibrating motor 19, elastic baffle 20, air inlet 21, high voltage power supply 22, insulation device 23, air outlet 24, air collecting cylinder 25, outer cylinder 26, inner cylinder 27, external release Electrode 28, internal disch...

Embodiment 2

[0040] A company in Nanning City is mainly engaged in the production of chemical fertilizers. In October 2016, the high-efficiency and energy-saving vortex spray coagulation electric bag composite dust collector of the present invention was adopted. See the attached figure 1 and Figure 3-11As shown, the dust collector of the present invention includes a dust inlet 1, a first-stage dust collector 2, a second-stage dust collector 3, an exhaust pipe 4, a third-stage dust collector 5, and a fourth-stage water spray dust collector 6 , sewage outlet 7, primary settling tank 8, secondary settling tank 9, tertiary settling tank 10, purified water outlet 11, limestone addition 12, support frame 13, primary dust collection tank 14, connecting pipe 15, connecting bolt 16 , Lime powder inlet 17, insulation layer 18, vibrating motor 19, elastic baffle 20, air inlet 21, high voltage power supply 22, insulation device 23, air outlet 24, air collector 25, outer cylinder 26, inner cylinder 27...

Embodiment 3

[0047] A company in Laibin City is mainly engaged in the production of mines. In January 2017, the high-efficiency and energy-saving spiral spray coagulation electric bag composite dust collector of the present invention was adopted. See the attached figure 1 and Figure 3-8 As shown, the dust collector of the present invention includes a dust inlet 1, a first-stage dust collector 2, a second-stage dust collector 3, an exhaust pipe 4, a third-stage dust collector 5, a fourth-stage water spray dust collector 6, Sewage outlet 7, primary settling tank 8, secondary settling tank 9, tertiary settling tank 10, purified water outlet 11, limestone addition 12, support frame 13, primary dust collection tank 14, connecting pipe 15, connecting bolt 16, Lime powder inlet 17, insulation layer 18, vibrating motor 19, elastic baffle 20, air inlet 21, high voltage power supply 22, insulation device 23, air outlet 24, air collecting cylinder 25, outer cylinder 26, inner cylinder 27, external r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com