Preparation and application method of adhesion substrate for artificial cultivation of porphyra yezoensis conchocelis

A technology of laver and attachment base, which is applied in the field of preparation of attachment base for artificial cultivation, can solve the problems of large amount of monomer shells, intolerant of drying out, occupation of labor costs, etc., and achieves the promotion of large-scale production and the area of attachment base Increase and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

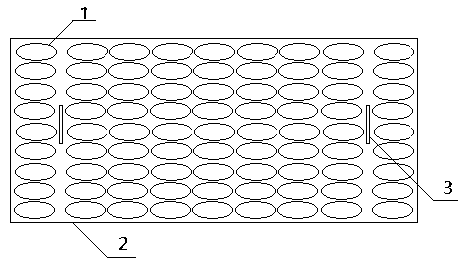

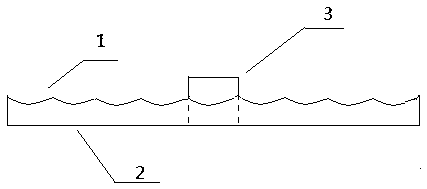

[0037] Example 1 A method for preparing an attachment base suitable for cultivating Porphyra zebra filaments

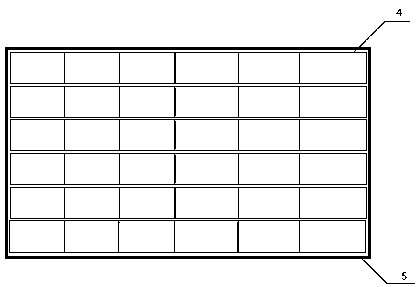

[0038] (1) Base mold: a rectangular wooden frame with an inner diameter of 30 x 60 cm made of wood as a mold for the cement base;

[0039] (2) Preparation of the cement base: After mixing the P.O32.5 Portland cement and medium sand with a particle size of 0.35mm in a mass ratio of 1:3, add 5% aluminum titanate accelerator Stir evenly with an appropriate amount of water; inject cement mortar into the base mold, and the thickness of the mortar is 2.5cm. When the cement mortar is injected, the auxiliary handles are pre-embedded at both ends of the cement base, and the oyster shell is fixed after the cement mortar is injected into the mold for 2 minutes;

[0040] (3) Pretreatment of oyster shells: oyster shells need to be pretreated before being fixed. First, shells should be selected from new shells with relatively flat shells of the year. The shell specifications shoul...

Embodiment 2

[0043] Example 2 A method for preparing an attachment base suitable for cultivating Porphyra zebra filaments

[0044] (1) Base mold: a rectangular wooden frame with an inner diameter of 30 x 60 cm made of wood as a mold for the cement base;

[0045] (2) Preparation of cement base: After mixing the P.O32.5 portland cement and medium sand with a particle size of 0.5mm in a mass ratio of 1:3, add 8% aluminum titanate accelerator Add appropriate amount of water and stir evenly; inject cement mortar into the base mold with a thickness of 3cm; when injecting cement mortar, pre-embed auxiliary handles at both ends of the cement base, and inject the cement mortar into the mold for 2 minutes before fixing the oyster shell;

[0046] (3) Pretreatment of oyster shells: oyster shells need to be pretreated before being fixed; first, shells should be selected from new shells with relatively flat shells of the year, and shells with a width of 3 to 8 cm should be selected for individual shells...

Embodiment 3

[0049] Example 3 A method for preparing an attachment base suitable for cultivating Porphyra zebra filaments

[0050] (1) Base mold: a rectangular wooden frame with an inner diameter of 30 x 60 cm made of wood as a mold for the cement base;

[0051] (2) Preparation of the cement base: After mixing the P.O32.5 Portland cement and medium sand with a particle size of 0.35mm in a mass ratio of 1:3, add 5% aluminum titanate accelerator Stir evenly with an appropriate amount of water; inject cement mortar into the base mold, and the thickness of the mortar is 2.5cm. When the cement mortar is injected, the auxiliary handles are pre-embedded at both ends of the cement base, and the cement mortar is injected into the mold for 2 minutes before the clam shell is fixed;

[0052] (3) Pretreatment of clam shells: clam shells need to be pretreated before being fixed. First, shells should be selected from new shells with relatively flat shells of the year. The shell specifications should be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com