Preparation method and application of alkali metal modified tin dioxide catalyst for methane oxidative coupling

A tin dioxide and methane oxidation technology, which is applied in metal/metal oxide/metal hydroxide catalysts, carbon compound catalysts, physical/chemical process catalysts, etc., can solve the problems of difficult industrialization, complex catalyst components, and high yield Less than 30% of the problem, to achieve excellent low temperature performance and stability, easy to control the preparation process, non-toxic and harmless solvent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

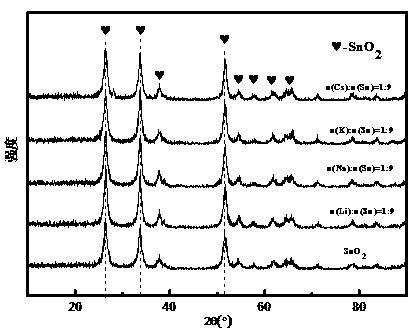

[0024] Weigh 15gSnCl 4 • 5H 2 O in a 500mL beaker, add 200mL of deionized water, stir to dissolve, and then add drop by drop of 25-28% ammonia water to adjust the pH to 7 to make Sn 4+ Ion precipitation is complete. After suction filtration, the precipitate is washed with deionized water to TDS 2 Carrier.

Embodiment 2

[0026] Weigh 15gSnCl 4 • 5H 2 O in a 500mL beaker, add 200mL of deionized water, stir to dissolve, and then dropwise add 25-28% of the mass fraction of ammonia water to adjust the pH to 7 to make Sn 4+ Ion precipitation is complete. After suction filtration, the precipitate is washed with deionized water to TDS 2 Carrier; weigh out 0.0670g LiNO 3 Add to 2mL deionized water solution, add 1.3590g of SnO after the salt is completely dissolved 2 The carrier is stirred for 5-6h, the resulting mixture is evaporated to dryness in a water bath at 80°C, and then dried and aged at 110-120°C for 12h, and then heated to 600°C in a muffle furnace at a heating rate of 2°C / min for 4h, Denoted as n(Li):n(Sn)=1:9.

Embodiment 3

[0028] Weigh 15gSnCl 4 • 5H 2 O in a 500mL beaker, add 200mL of deionized water, stir to dissolve, and then dropwise add 25-28% of the mass fraction of ammonia water to adjust the pH to 7 to make Sn 4+ Ion precipitation is complete. After suction filtration, the precipitate is washed with deionized water to TDS 2 Carrier; weigh out 0.0849g NaNO 3 Add to 2mL deionized water solution, add 1.3590g of SnO after the salt is completely dissolved 2 The carrier is stirred for 5-6h, the resulting mixture is evaporated to dryness in a water bath at 80°C, and then dried and aged at 110-120°C for 12h, and then heated to 600°C in a muffle furnace at a heating rate of 2°C / min for 4h, Denoted as n(Na):n(Sn)=1:9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com