Plasma-type tungsten oxide-modified graphite phase carbon nitride nanosheet composite photocatalyst and preparation method and application thereof

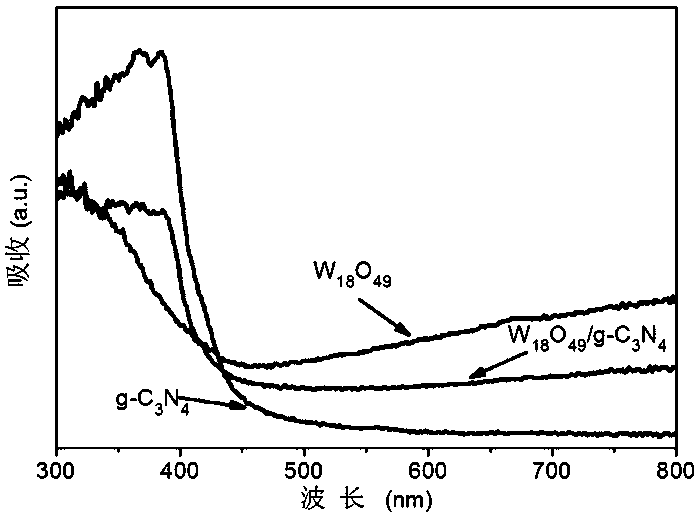

A technology of graphite phase carbon nitride and phase carbon nitride, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Advanced problems, to achieve the effect of improving photocatalytic activity and photocatalytic capacity, high photocatalytic activity, and improving absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

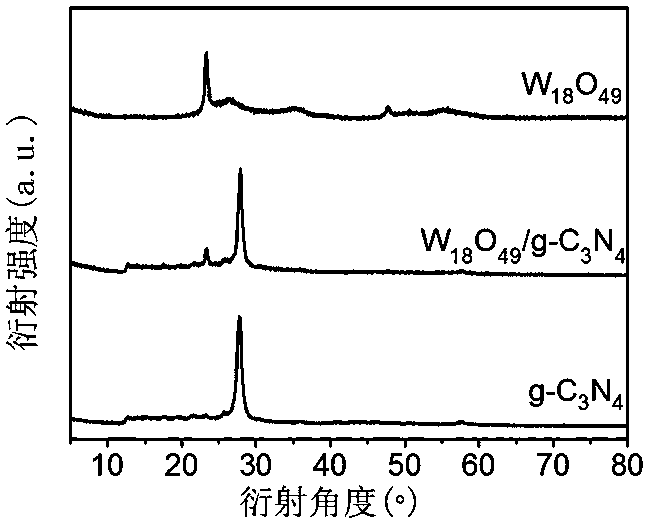

[0037] A composite photocatalyst of plasma-type tungsten oxide modified graphite-phase carbon nitride nanosheets, including plasma-type tungsten oxide and graphite-phase carbon nitride nanosheets, plasma-type tungsten oxide is attached to the surface of graphite-phase carbon nitride nanosheets, and the plasmonic Body type tungsten oxide is.

[0038] In this embodiment, the mass ratio of plasma-type tungsten oxide and graphite-phase carbon nitride nanosheets is 1:3.

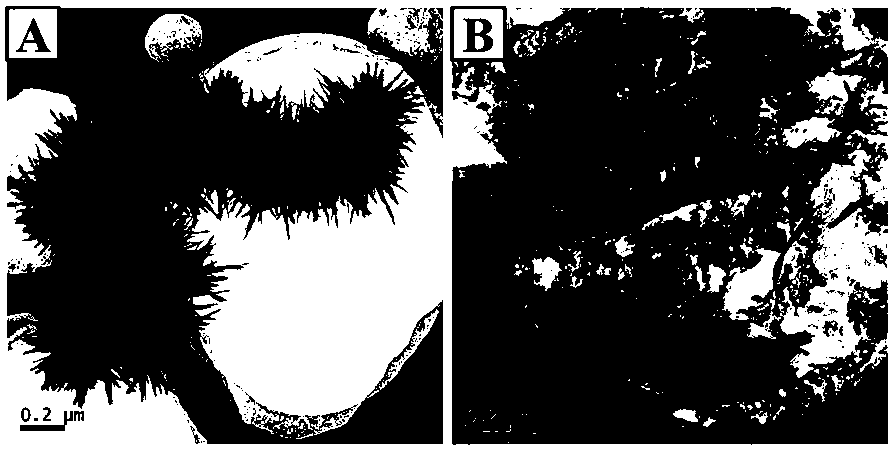

[0039] In this embodiment, the plasma-type tungsten oxide is composed of nanowires and has a sea urchin structure.

[0040] In this embodiment, plasma-type tungsten oxide is attached to the surface of graphite-phase carbon nitride nanosheets by means of self-assembly to form a grass structure.

[0041] A method for preparing the plasma-type tungsten oxide modified graphite phase carbon nitride nanosheet composite photocatalyst of the above-mentioned embodiment, comprising the following steps:

[0042] (1) Prepar...

Embodiment 2

[0056] A kind of graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide is basically the same as the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide in embodiment 1, the difference is: implement The mass ratio of plasma-type tungsten oxide and graphite-phase carbon nitride nanosheets in the plasma-type tungsten oxide-modified graphite-phase carbon nitride nanosheet composite photocatalyst of Example 2 is 1:2.5.

[0057] A preparation method of the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide is basically the same as the preparation method of the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide in Example 1, The difference is that the amount of graphitic carbon nitride nanosheets used in Example 2 is 80 mg.

[0058] The plasma-type tungsten oxide-modified graphite-ph...

Embodiment 3

[0060] A kind of graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide is basically the same as the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide in embodiment 1, the difference is: implement The mass ratio of plasma-type tungsten oxide and graphite-phase carbon nitride nanosheets in the plasma-type tungsten oxide-modified graphite-phase carbon nitride nanosheet composite photocatalyst of Example 3 is 1:4.

[0061] A preparation method of the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide is basically the same as the preparation method of the graphite phase carbon nitride nanosheet composite photocatalyst modified by plasma type tungsten oxide in Example 1, The difference is that the amount of graphitic carbon nitride nanosheets used in Example 3 is 120 mg.

[0062] The plasma-type tungsten oxide-modified graphite-pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com