Quaternized polymer brush antibacterial material based on Si-ATRP (Surface-initiated Atom Transfer Radical Polymerization) method and preparation method of antibacterial material

A technology of polymer brushes and antibacterial materials, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problems of silver ion instability, low antibacterial immediate effect, heat resistance Insufficient resistance and other problems, to achieve the effect of easy industrial production, low cost, good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

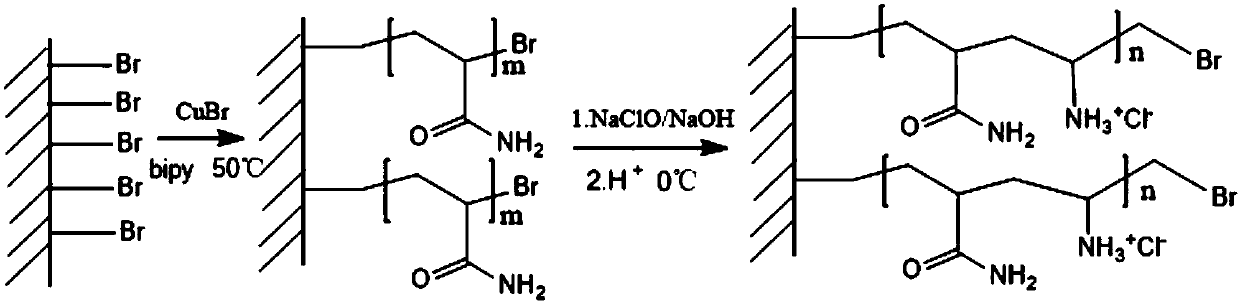

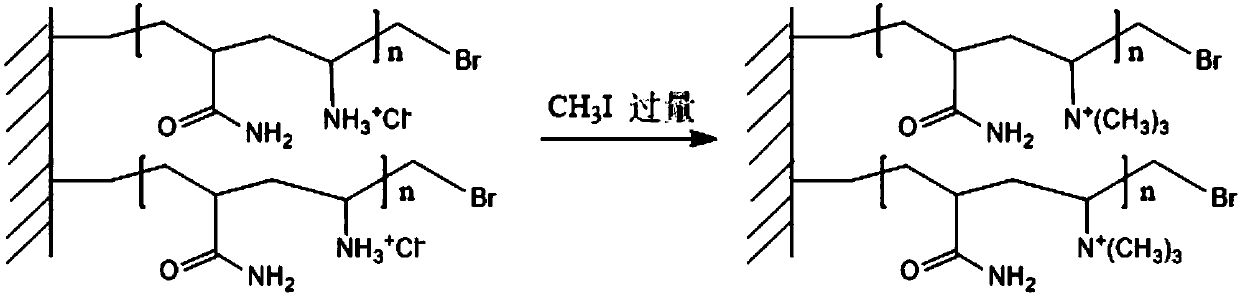

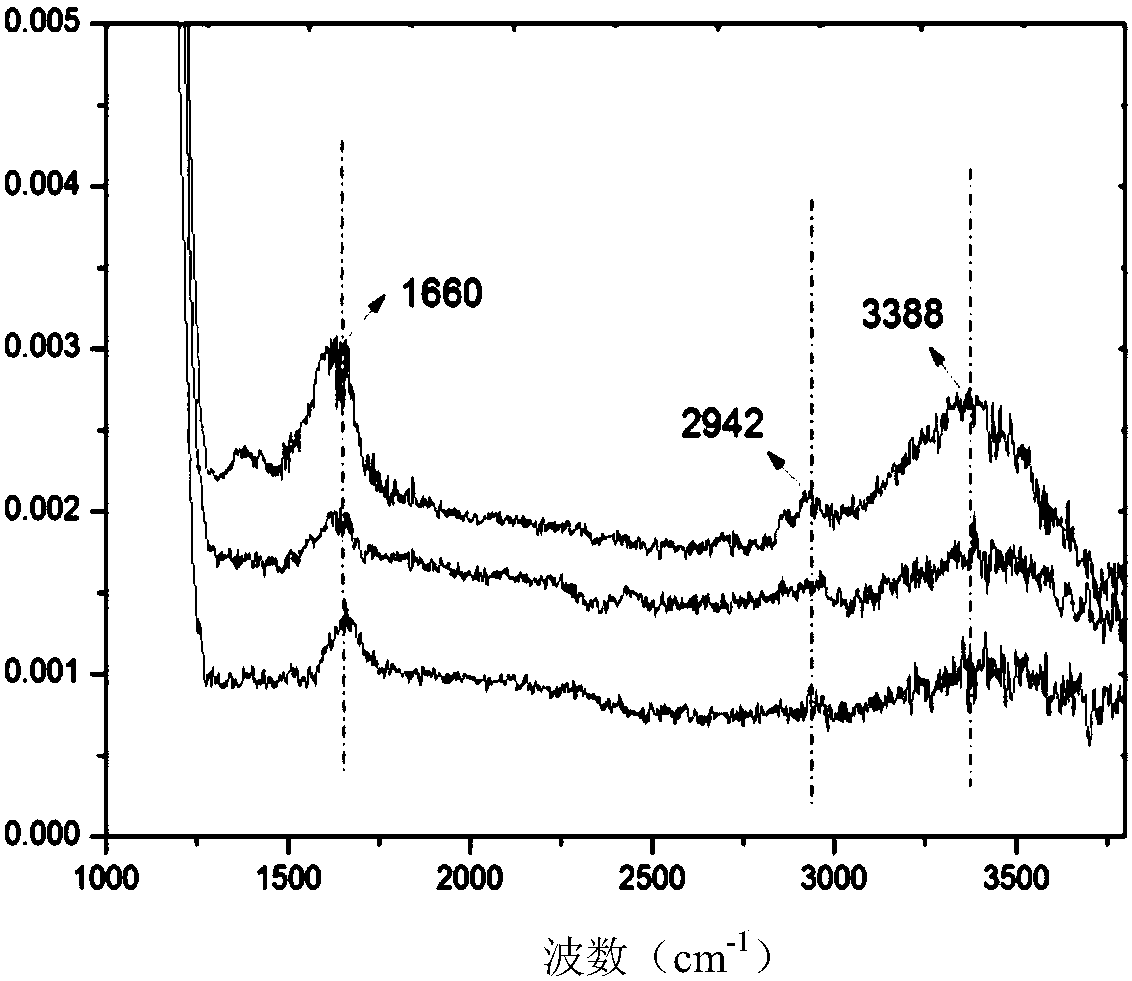

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of the quaternized polymer brush antibacterial material based on Si-ATRP method, comprises the following steps:

[0040] (1) Hydroxylation and amination treatment of glass and fixation of initiator

[0041] (1-1) Use a glass sheet with a size of 20*10mm, soak it in a solution of methanol:HCl (V:V)=1:1 for 30 minutes, then ultrasonically clean it in ethanol and deionized water for 15 minutes, and then place it in a concentration of Soak in 1mol / L sodium hydroxide solution for 1 hour, wash the glass slide with a large amount of deionized water, blow it dry with nitrogen, put it in a drying oven at 60°C and dry it thoroughly to obtain hydroxylated glass;

[0042] (1-2) Configure a 3-aminopropyltriethoxysilane water (APTES) solution with a volume fraction of 1% (it needs to be stirred at room temperature (25°C) for 2 hours during preparation, and mixed with 0.22um 2 filter membrane); soak the hydroxylated glass sheet in APTES aqueous solution f...

Embodiment 2

[0051] A kind of preparation method of the quaternized polymer brush antibacterial material based on Si-ATRP method, comprises the following steps:

[0052] (1) Hydroxylation and amination treatment of glass and fixation of initiator

[0053] (1-1) Use a glass sheet with a size of 20*10mm, soak it in a solution of methanol:HCl (V:V)=1:1 for 30 minutes, then ultrasonically clean it in ethanol and deionized water for 15 minutes, and then place it in a concentration of Soak in 1mol / L sodium hydroxide solution for 2 hours, wash the glass slide with a large amount of deionized water, blow dry with nitrogen, put it in a drying oven at 60°C and dry it thoroughly to obtain hydroxylated glass;

[0054] (1-2) Configure a 3-aminopropyltriethoxysilane water (APTES) solution with a volume fraction of 1% (it needs to be stirred at room temperature (25°C) for 2 hours during preparation, and mixed with 0.22um 2 filter membrane); soak the hydroxylated glass sheet in APTES aqueous solution for...

Embodiment 3

[0061] A kind of preparation method of the quaternized polymer brush antibacterial material based on Si-ATRP method, comprises the following steps:

[0062] (1) Hydroxylation and amination treatment of glass and fixation of initiator

[0063] (1-1) Use a glass sheet with a size of 20*10mm, soak it in a solution of methanol:HCl (V:V)=1:1 for 30 minutes, then ultrasonically clean it in ethanol and deionized water for 15 minutes, and then place it in a concentration of Soak in 1mol / L sodium hydroxide solution for 2 hours, wash the glass slide with a large amount of deionized water, blow dry with nitrogen, put it in a drying oven at 60°C and dry it thoroughly to obtain hydroxylated glass;

[0064] (1-2) Configure a 3-aminopropyltriethoxysilane water (APTES) solution with a volume fraction of 1% (it needs to be stirred at room temperature (25°C) for 2 hours during preparation, and mixed with 0.22um 2 filter membrane); soak the hydroxylated glass sheet in APTES aqueous solution for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com