A kind of alternating micro-layered heat-conducting PBX mixed explosive and its preparation method

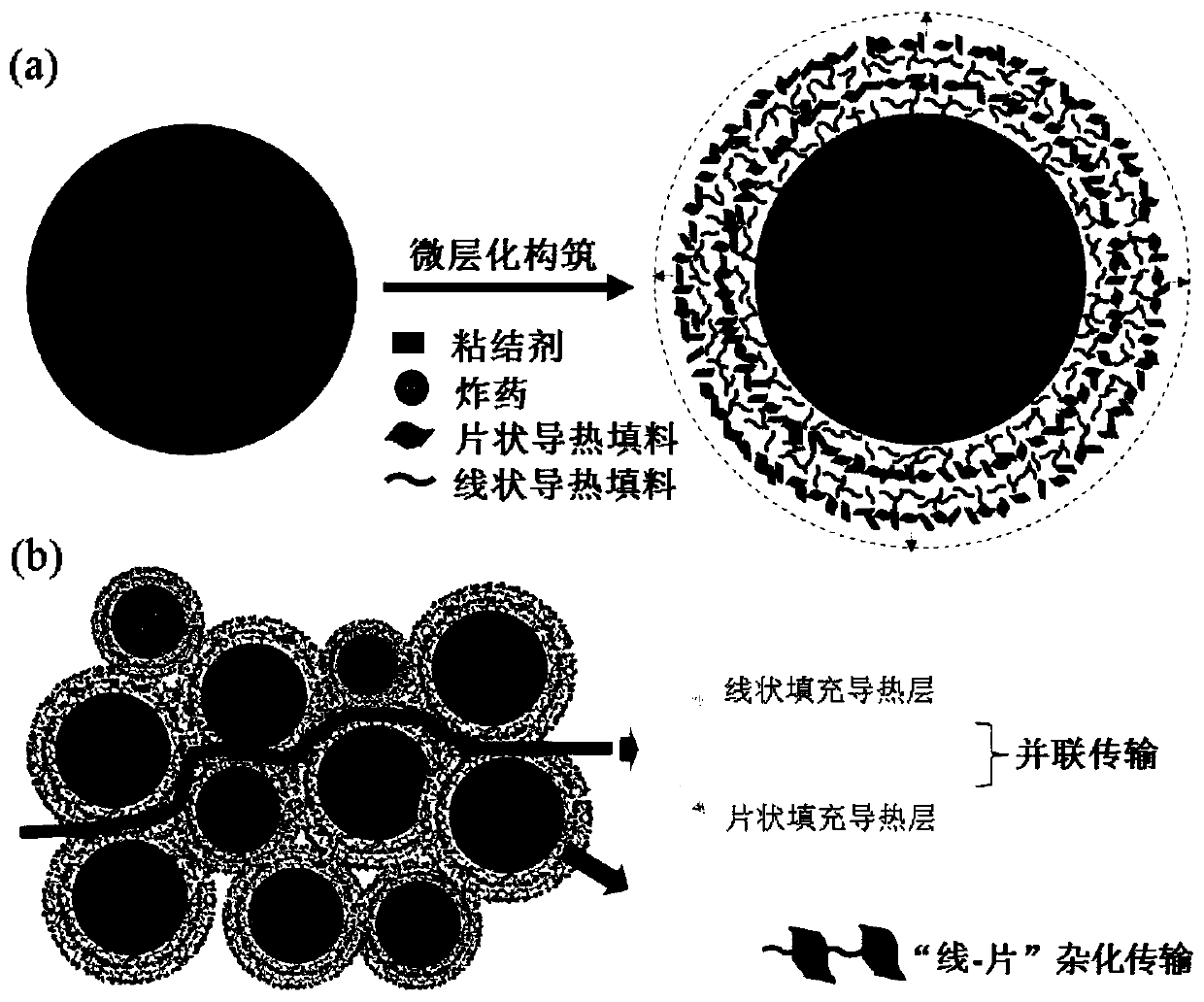

A technology of mixed explosives and microlayers, which is applied in the directions of explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, aromatic nitrated compositions, etc., can solve the requirements and limitations of improving and failing to meet the thermal conductivity of PBX mixed explosives Thermal conductivity and other issues, to achieve the effect of solving the low thermal conductivity, easy to implement, and improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Weigh 95g of 1,3,5-triamino-2,4,6-trinitrobenzene and 100g of deionized water, stir at 400rpm for 15min to form an explosive suspension, and heat it to 70°C with a water bath , dropwise add a polymer solution composed of 2.7g vinylidene fluoride and chlorotrifluoroethylene copolymer (monomer ratio 1:4), vacuumize at the same time, granulate the explosive powder, and stir the material for 5 minutes, filter and deionize the material After washing with water and drying, the pre-shaped PBX modeling powder can be obtained.

[0027] Step 2: Weigh 100g, 2g, 100g of deionized water, multi-walled carbon nanotubes, and zirconia ball milling beads respectively, and use a planetary ball mill for ball milling. , dry for use. Then, 0.45g of flake graphene and 0.05g of ball-milled linear carbon nanotubes were added to ethyl acetate, ultrasonically dispersed for 15min, and then added to 1.8g of vinylidene fluoride and chlorotrifluoroethylene copolymer (monomer In the polymer ...

Embodiment 2

[0030] Step 1: Weigh 95g of 1,3,5-triamino-2,4,6-trinitrobenzene and 100g of deionized water, stir at 400rpm for 15min to form an explosive suspension, and heat it to 70°C with a water bath , dropwise add a polymer solution made up of 2.7g vinylidene fluoride and chlorotrifluoroethylene copolymer (monomer ratio 1:1), vacuumize at the same time, granulate the explosive powder, and stir the material for 5 minutes, filter and deionize the material After washing with water and drying, the pre-shaped PBX modeling powder can be obtained.

[0031]Step 2: Weigh 100g, 2g, and 100g of deionized water, multi-walled carbon nanotubes, and zirconia ball-milled beads, respectively, and use a planetary ball mill to perform ball milling at a speed of 150-500rpm for 60min, filter, and wash with deionized water. Dry and set aside. Then 0.35g flake graphene and 0.15g ball-milled linear carbon nanotubes were added respectively in ethyl acetate, ultrasonically dispersed for 15min, and then respect...

Embodiment 3

[0034] Step 1: Weigh 93g of 1,3,5-triamino-2,4,6-trinitrobenzene, 100g of deionized water, stir at 400rpm for 15min to form an explosive suspension, and heat to 70°C in a water bath , add dropwise a polymer solution made of 3.6g of vinylidene fluoride and chlorotrifluoroethylene copolymer (monomer ratio 1:3), and vacuumize at the same time, the explosive powder is granulated, and after stirring for 5 minutes, filter and deionize the material After washing with water and drying, the preformed PBX modeling powder can be obtained.

[0035] Step 2: Weigh 100g, 2g, and 100g of deionized water, single-walled carbon nanotubes, and zirconia ball-milled beads, respectively, and use a planetary ball mill for ball milling at a speed of 150-500rpm for 60 minutes, filter, and wash with deionized water , dry and set aside. Then 0.5g of boron nitride nanosheets and 0.5g of ball-milled single-walled carbon nanotubes were added to ethyl acetate, ultrasonically dispersed for 15min, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com