Preparation method of LED remote excitation fluorescent powder layer

A phosphor layer and remote excitation technology, which is applied to semiconductor devices of light-emitting elements, light sources, lighting and heating equipment, etc. problems such as light extraction efficiency, to avoid yellowing and light decay, simplify the packaging process, and improve the effect of small production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for LED remote excitation phosphor layer, characterized in that: the method comprises the following steps:

[0033] (1) Preparation of alumina suspension: mix alumina and deionized water according to the required ratio to obtain a suspension with uniform dispersion of alumina;

[0034](2) Configure the adhesive: according to the needs, select the surface adhesive material used to configure the transparent colloid with the required concentration;

[0035] (3) Configure surfactant: obtain a certain concentration of surfactant solution;

[0036] (4) Prepare phosphor powder paste: according to the required luminescent characteristics, weigh a certain amount of phosphor powder, add the three solutions prepared in steps (1), (2), and (3), and stir well to obtain Phosphor paste required;

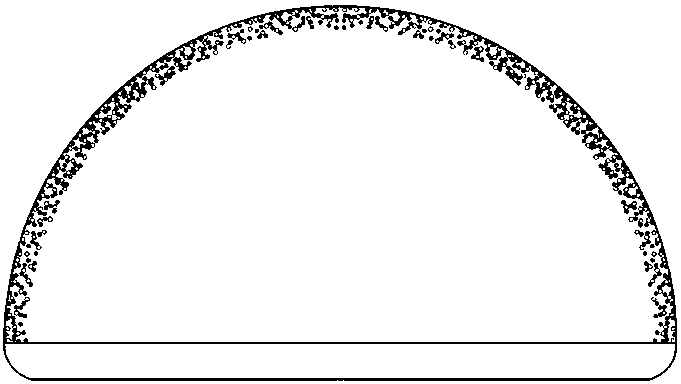

[0037] (5) Phosphor powder slurry coating and drying: use the selected coating method to coat the phosphor powder slurry on the inner wall of the lampshade, and then d...

Embodiment 2

[0040] According to the preparation method of the LED remote excitation phosphor layer described in Example 1, in the step (1), the alumina used is ultrafine nanometer γ-phase alumina, and its particle size is nano-scale particle size distribution , the concentration of the prepared alumina suspension is 10%~20%.

Embodiment 3

[0042] According to the preparation method of LED remote excitation phosphor layer described in embodiment 1 or 2, in step (2), the binder used is a water-soluble binder, mainly including polyethylene oxide, polyvinyl alcohol, hydroxyl One or more of ammonium methylcellulose, polyacrylic acid, ammonium polyacrylate, and polymethacrylic acid are mixed, and the concentration of the prepared water-soluble binder is 1% to 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com