Flat heat pipe, manufacturing method and phase change heat storage and release device

A flat heat pipe, heat storage and release technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc. Compact structure, stable heat storage and release, and short thermal response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to facilitate those skilled in the art to understand and realize the present invention, the flat heat pipe, the manufacturing method of the flat heat pipe and the phase change heat storage and release device made of the flat heat pipe according to the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

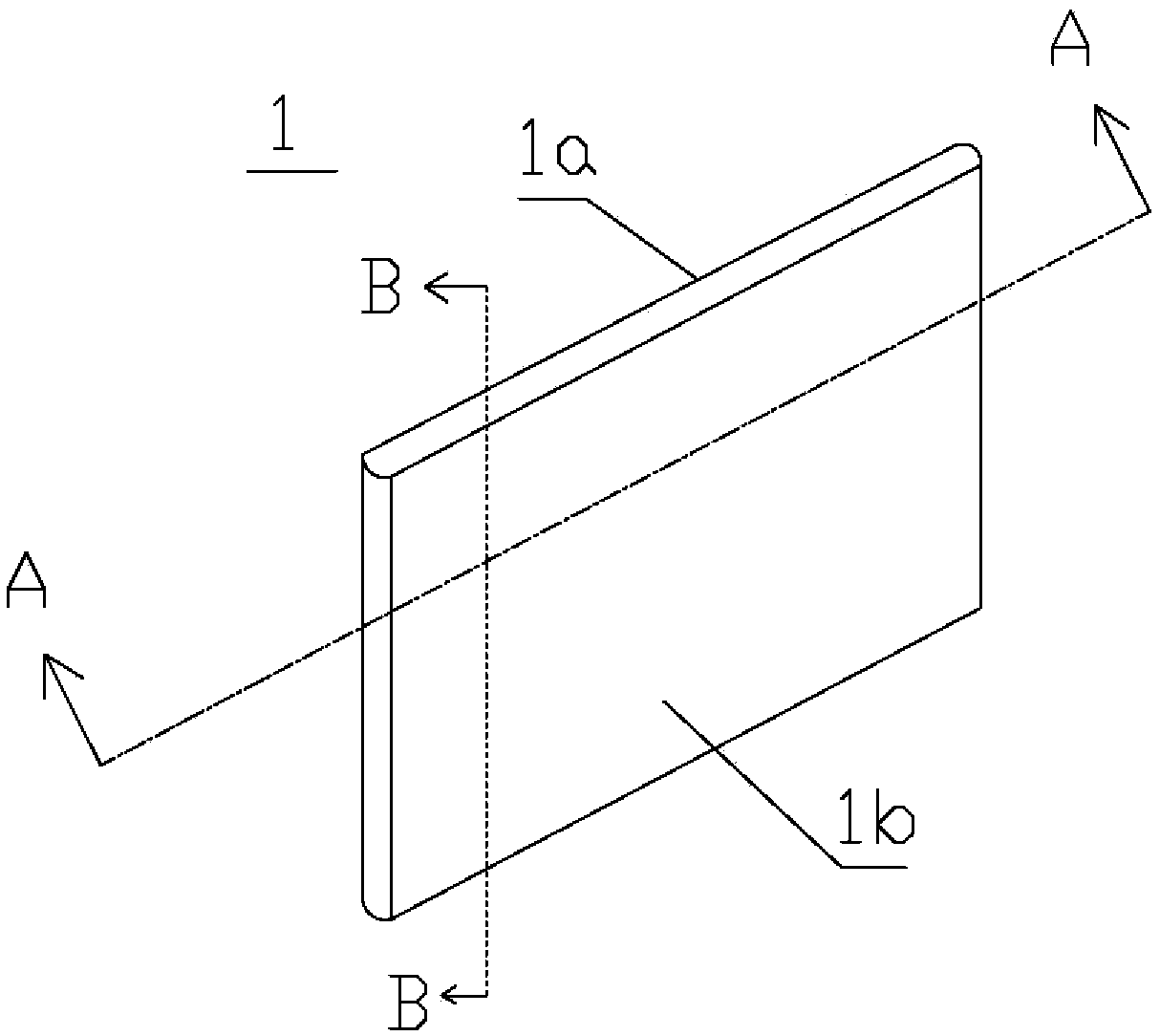

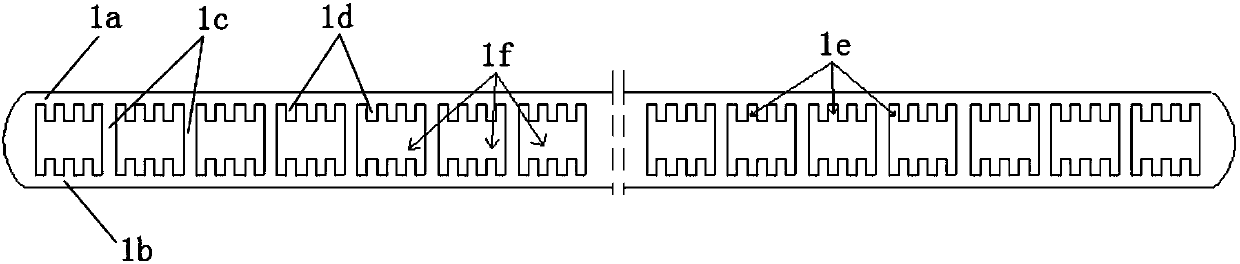

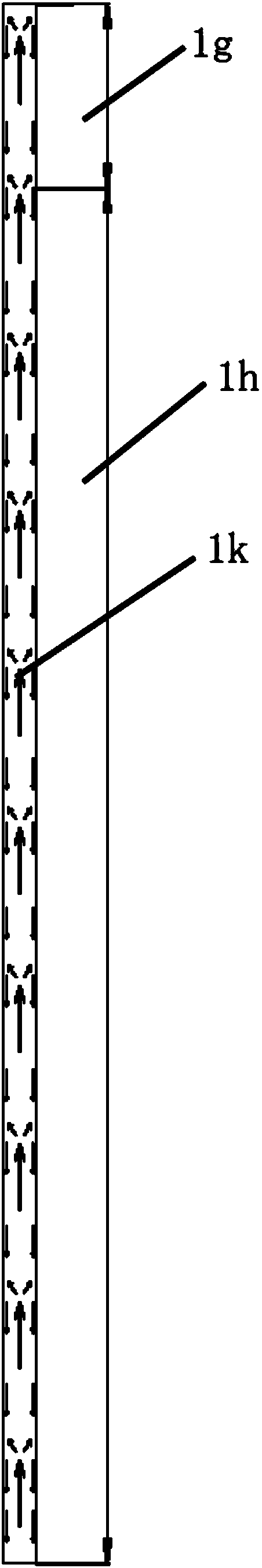

[0073] Such as figure 1 , figure 2 Shown is a flat heat pipe 1, including inner and outer plates 1a, 1b and a grid 1c, the grid 1c is fixedly connected with the inner walls of the inner and outer plates 1a, 1b, and divides the inner cavity of the flat heat pipe into a plurality of interconnected The cavity 1f, the inner walls of the inner and outer plates 1a, 1b are all provided with a plurality of protrusions 1d, and grooves 1e are formed between adjacent protrusions 1d or between the grid 1c and the protrusions 1d.

[0074] Such as figure 2 As shown, both the protrusion 1d and the groove 1e a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com