Method for preparation of graphene electrode MoS2 field effect transistor through thermal reduction

A field-effect transistor and graphene electrode technology, which is applied in the field of large-scale preparation of high-performance MoS2 field-effect transistors, can solve the problems of complex preparation process of MoS2 field-effect transistors and inapplicability to large-scale manufacturing, and solve the problem of photoresist residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The substantive features and remarkable progress of the present invention will be further described below through specific implementation, but the present invention is by no means limited to the described embodiments.

[0011] The specific implementation steps are as follows:

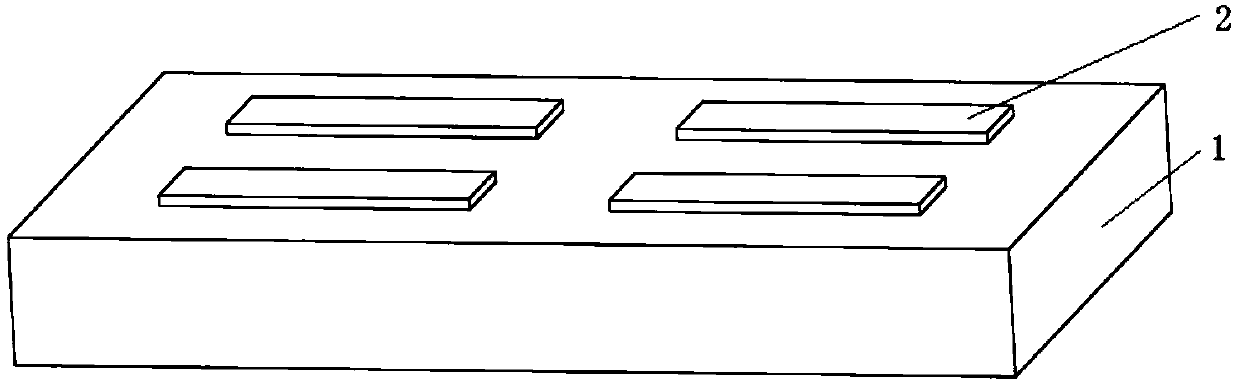

[0012] 1. Add 0.03g MoO 3 The powder and 0.01g S powder were placed in different quartz cups in the tube furnace. MoO 3 Keep the distance from S powder at 18-20cm. SiO 2 / Si substrate on MoO 3 Above the powdered quartz cup. Heat the tube furnace to 650° C. and pass Ar gas (10-20 sccm) into the tube furnace for 30-60 min to obtain a single layer of MoS2.

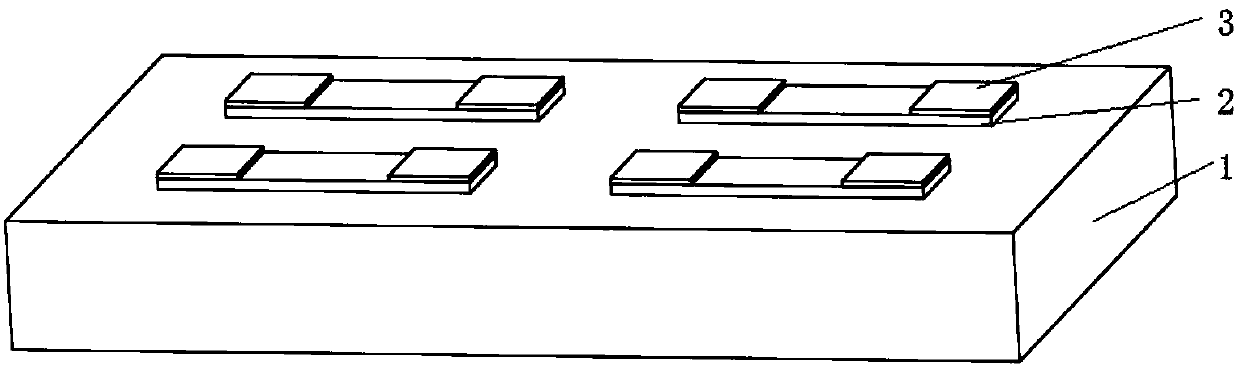

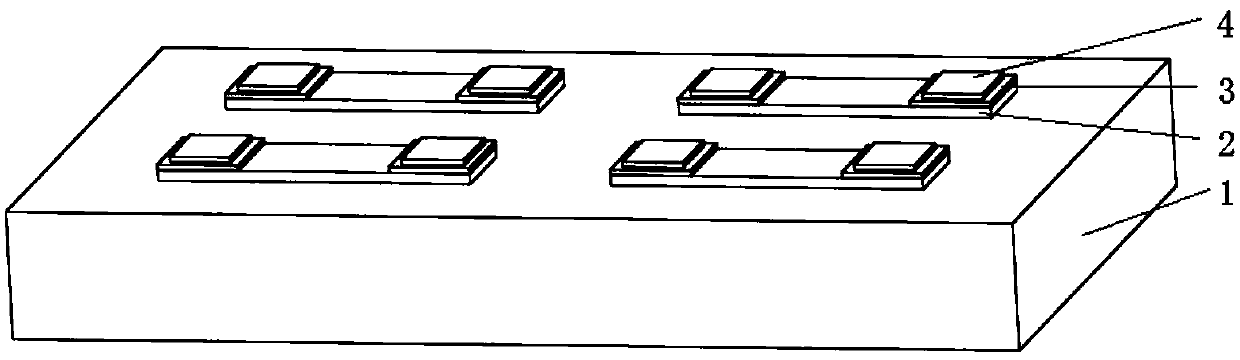

[0013] 2. On the prepared MoS2 sample, deposit PPA / SiO respectively 2 / PPA(20nm / 3nm / 9nm), and use the thermal scanning probe to directly write the size and shape of the desired MoS2 channel. Use O 2 / N 2 Thinning of 9nm PPA by reactive ion etching followed by CHF 3 Reactive Ion Etching SiO 2 layer, finally using O 2 Reactive ion etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com