Aerospace precision industrial cleaning agent

An aerospace precision and cleaning agent technology, applied in the field of cleaning agents, can solve problems such as potential safety hazards and affecting launch missions, and achieve the effects of reducing COD value, low cleaning cost, and mild cleaning conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 7

[0053] The proportioning of cleaning agent in embodiment 1 to embodiment 7 is shown in table 1.

[0054] The proportioning of each component in cleaning agent in table 1 embodiment 1 to embodiment 7

[0055]

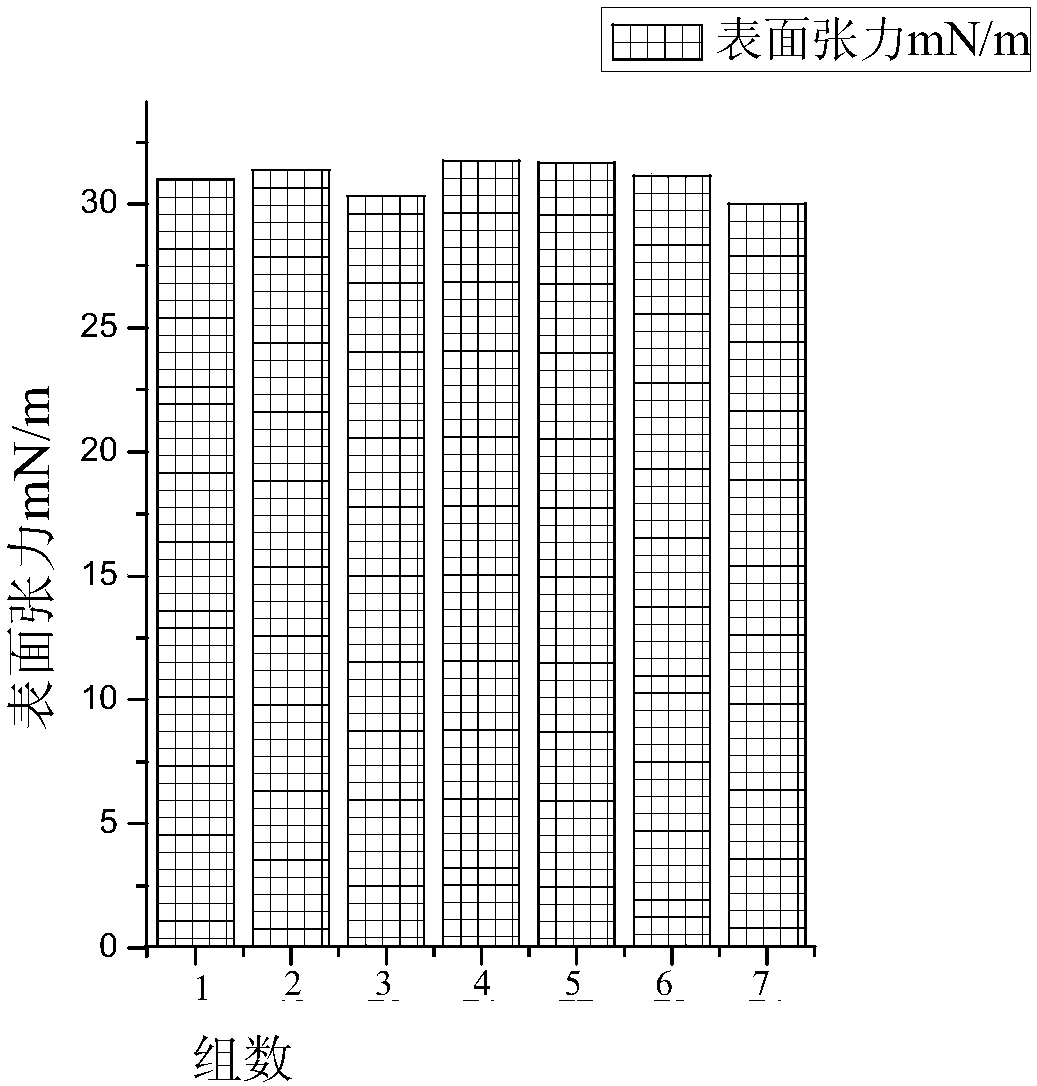

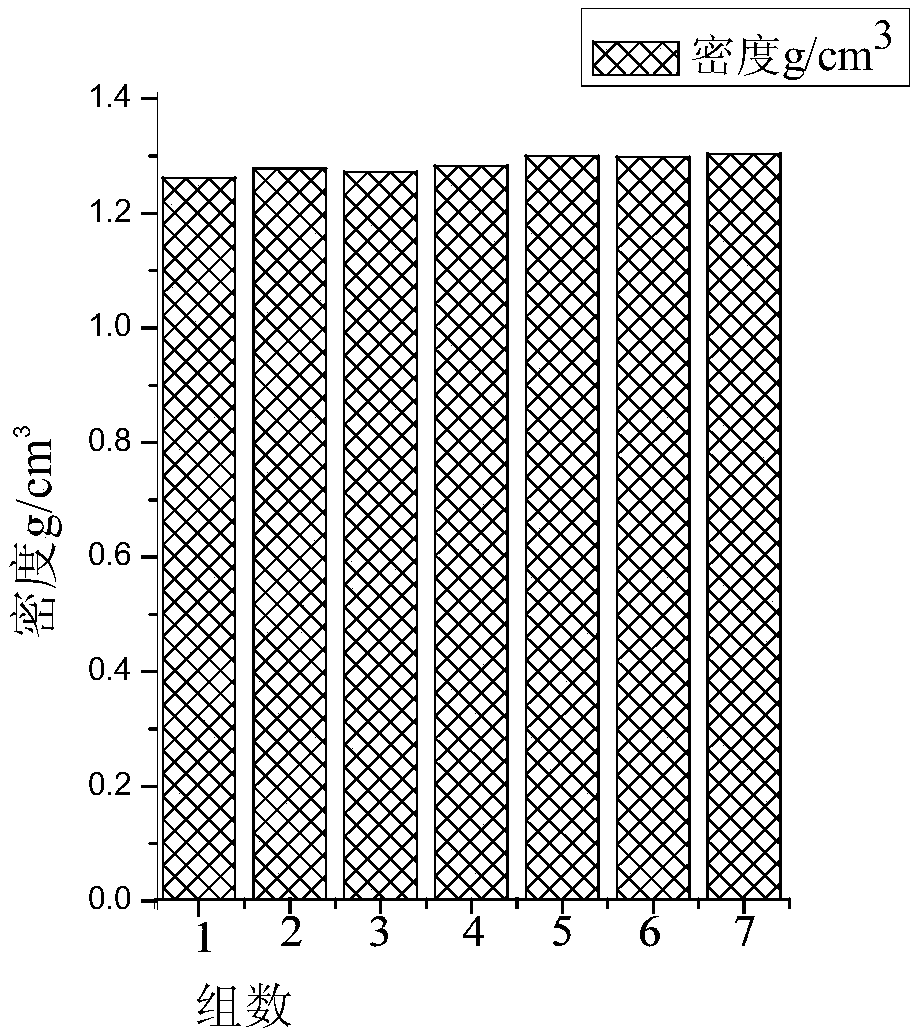

[0056] Carry out test experiment to the cleaning agent of embodiment 1 to embodiment 7.

[0057] (1) KB value analysis

[0058] The KB value of table 2 embodiment 1 to embodiment 7 cleaning agents

[0059]

[0060] The KB values of Embodiment 1 to Embodiment 7 are shown in Table 1. The KB value represents the index of the relative solubility of hydrocarbon solvents. The larger the KB value, the stronger the solvent solubility. For cleaning agent solutions, the KB value is not required to be too high. If the KB value is too high, the solubility is large.

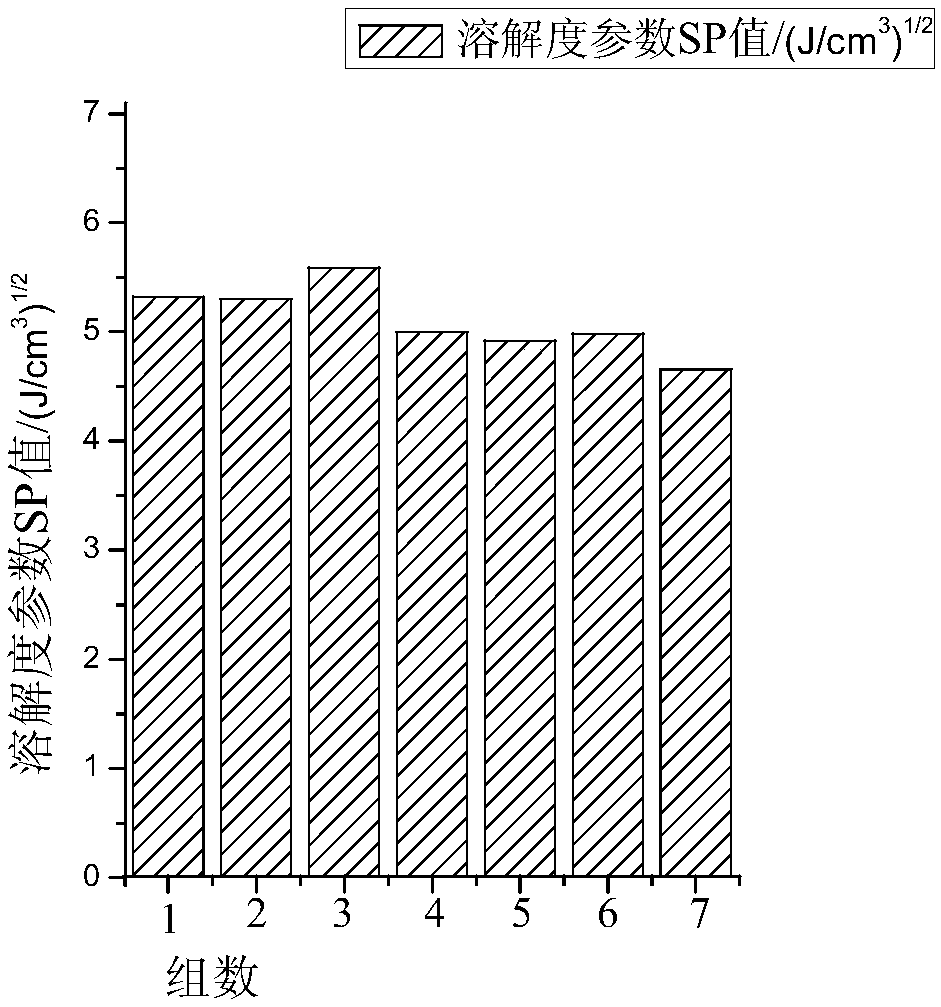

[0061] (2) Analysis of solubility parameter SP value

[0062] The solubility parameter SP value of embodiment 1 to embodiment 7 sees figure 1 ,from figure 1 It can be seen that the overall data is basicall...

Embodiment 8 to Embodiment 19

[0083] See Table 3 for the proportioning of the cleaning agents of Examples 8 to 19.

[0084] The proportioning of each component in table 3 embodiment 8 to embodiment 19

[0085]

[0086] Various performances of the cleaning agents of Examples 8 to 19 were tested. For specific test results, see Figure 7 to Figure 13 ,in, Figure 7 to Figure 13 The numbers A1, A2, A3, B1, B2, B3, C1, C2, C3, D1, D2 and D3 on the middle abscissa represent Embodiment 8 to Embodiment 19 in sequence.

[0087] (1) KB value analysis

[0088] Such as Figure 7 Shown, the KB value of embodiment 8 to embodiment 19 cleaning agent satisfies the requirement of precision cleaning agent in theory, and the KB value of precision cleaning agent can not be too high, if the metal material surface of cleaning has composite material, KB value can be too high Surface composite material dissolves, causing damage to cleaned material. Dichloromethane content is at 93%-95%, and when ethanol, ethyl acetate con...

Embodiment 20 to Embodiment 23

[0102] See Table 4 for the proportioning of the cleaning agents in Example 20 to Example 23.

[0103] The proportioning of each component in the cleaning agent of table 4 embodiment 20 to embodiment 23

[0104]

[0105] In Example 21 to Example 23, the mass percentage of nonionic surfactant in the cleaning agent is 2%, and the mass ratio of dichloromethane, ethanol and ethyl acetate in the cleaning agent is 93% respectively , 3% and 2%.

[0106] Nonionic surfactants used:

[0107] Performance parameters of EL-20: name: castor oil polyoxyethylene ether; appearance: light yellow liquid; hydroxyl value: 90-100; PH: 5-7.

[0108] Performance parameters of OP-10: name: octylphenol polyoxyethylene ether; appearance: yellow viscous liquid; hydroxyl value: 83-93; PH: 5-7.

[0109] Performance parameters of TWEEN-20: name: sorbitol polyoxyethylene ether; appearance: light yellow viscous liquid; hydroxyl value: 90-110; PH: 5-7.

[0110]Various performances of the cleaning agents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com