Efficient aluminum alloy refining agent and preparation method thereof

A refining agent and aluminum alloy technology, which is applied in the field of aluminum alloy processing, can solve the problems of high hydrogen content and non-metallic inclusion content, and achieve the effects of good impurity removal effect, strong degassing ability, and uniform microstructure compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

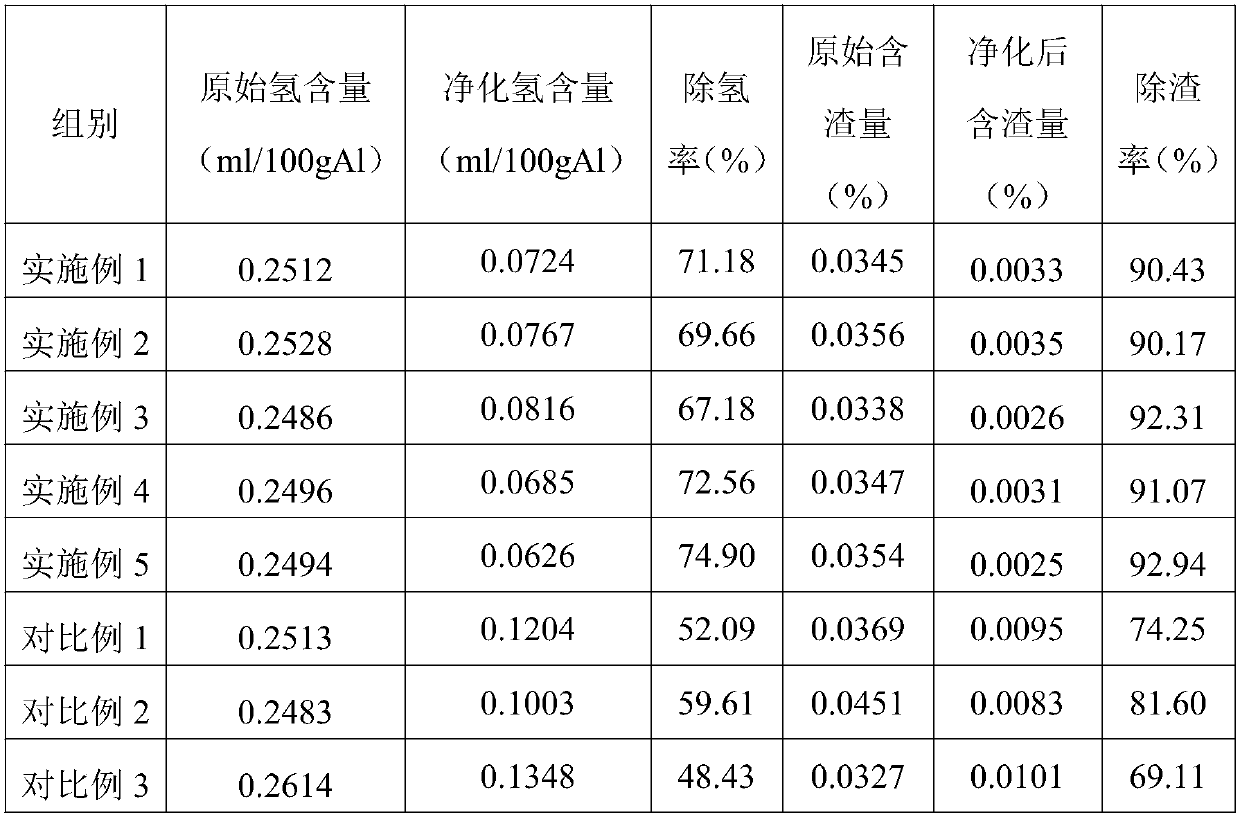

Examples

preparation example Construction

[0024] The preparation method of the high-efficiency refining agent for aluminum alloy comprising the above raw materials and components comprises the following steps:

[0025] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 120-130g / L, heat the solution to 72-75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, and dry the precipitate until the water content is ≤2% , crushed to a particle size of ≤2mm, and dehydrated under the condition of a vacuum of 0.5-0.8MPa to obtain F 3 La powder;

[0026] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 120-130g / L, heat the solution to 72-75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, and dry the precipitate until the water content is ≤2% , Grinding to particle size ≤ 2mm, and dehydrating under the condition of vacuum degree of 0.5-0.8MPa to obtain FNd powder;

[0027] S3: KCl, NaCl, KNO 3 , A1F 3 , MgF 2 、Na 3 A1F 6 、Na 2 SiF 6 Put the po...

Embodiment 1

[0030] A high-efficiency refining agent for aluminum alloys, in parts by weight, comprising the following components: 30 parts of KCl, 30 parts of NaCl, KNO 3 30 copies, A1F 3 11 parts, MgF 2 4 parts, Na 3 A1F 6 5 parts, Na 2 SiF 6 7 parts, FNd 0.2 parts, F 3 La0.7 parts;

[0031] The preparation method of the high-efficiency refining agent for aluminum alloy comprising the above raw materials and components comprises the following steps:

[0032] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 120g / L, heat the solution to 75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the precipitate to a water content of ≤2%, and crush to particle size ≤2mm, dehydration under the condition of vacuum degree of 0.6MPa to get F 3 La powder;

[0033] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 120g / L, heat the solution to 75°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the preci...

Embodiment 2

[0037] A high-efficiency refining agent for aluminum alloys, in parts by weight, comprising the following components: 40 parts of KCl, 24 parts of NaCl, KNO 3 40 copies, A1F 3 7 parts, MgF 2 3 parts, Na 3 A1F 6 4 parts, Na 2 SiF 6 3 parts, FNd 0.6 parts, F 3 La 0.5 parts;

[0038] The preparation method of the high-efficiency refining agent for aluminum alloy comprising the above raw materials and components comprises the following steps:

[0039] S1: La 2 o 3 Dissolve in hydrochloric acid and dilute to 130g / L, heat the solution to 74°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the precipitate to a water content of ≤2%, and crush to particle size ≤2mm, dehydration under the condition of vacuum degree of 0.5MPa to get F 3 La powder;

[0040] S2: put Nd 2 o 3 Dissolve in hydrochloric acid and dilute to 130g / L, heat the solution to 74°C, add 48% hydrofluoric acid, stir to obtain a precipitate, then wash, filter, dry the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com