Preparation method of lithium-sulfur battery diaphragm

A lithium-sulfur battery and separator technology, which is applied in the field of preparation of lithium-sulfur battery separators, can solve the problems of poor cycle stability, poor rate characteristics, and damage to the positive electrode sulfur-containing structure of lithium-sulfur batteries, and achieves inhibition of polysulfide diffusion, good mechanical and conductivity, avoiding the effect of shuttling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The third embodiment of the present invention further provides a method for preparing a lithium-sulfur battery separator. The preparation method of the lithium-sulfur battery diaphragm comprises the following steps:

[0035] S1: providing a diaphragm base; and

[0036] S2: forming a functional layer on a surface of the diaphragm substrate, the method for forming the functional layer includes:

[0037] S21: laying a first carbon nanotube layer on the surface of the membrane substrate;

[0038] S22: Provide a plurality of manganese dioxide nanoparticles and a plurality of graphene oxide sheets, disperse the plurality of manganese dioxide nanoparticles and a plurality of graphene oxide sheets in a solvent to obtain a mixture, and uniformly deposit the mixture on the A first graphene oxide composite layer is formed on the surface of the first carbon nanotube layer;

[0039] S23: laying a second carbon nanotube layer on the surface of the first graphene oxide composite la...

Embodiment 1

[0058] The sulfur-carbon nanotube composite electrode is used as the positive electrode, the metal lithium sheet is used as the negative electrode, and the 1,3-dioxolane (DOL) / ethylene glycol dimethyl ether (DME)-based bis(trifluoromethanesulfonic acid) ) lithium imide (LiTFSI) as the electrolyte to form a lithium-sulfur battery. Among them, the mass proportion of sulfur loaded on the positive pole piece is 75 wt%.

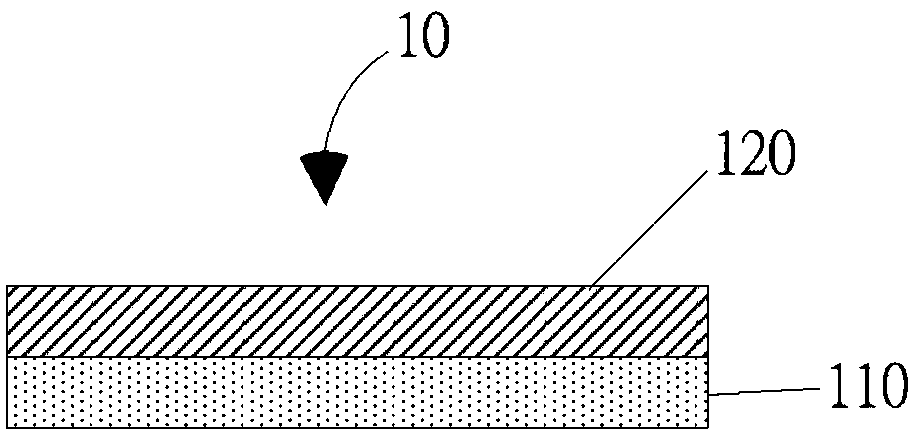

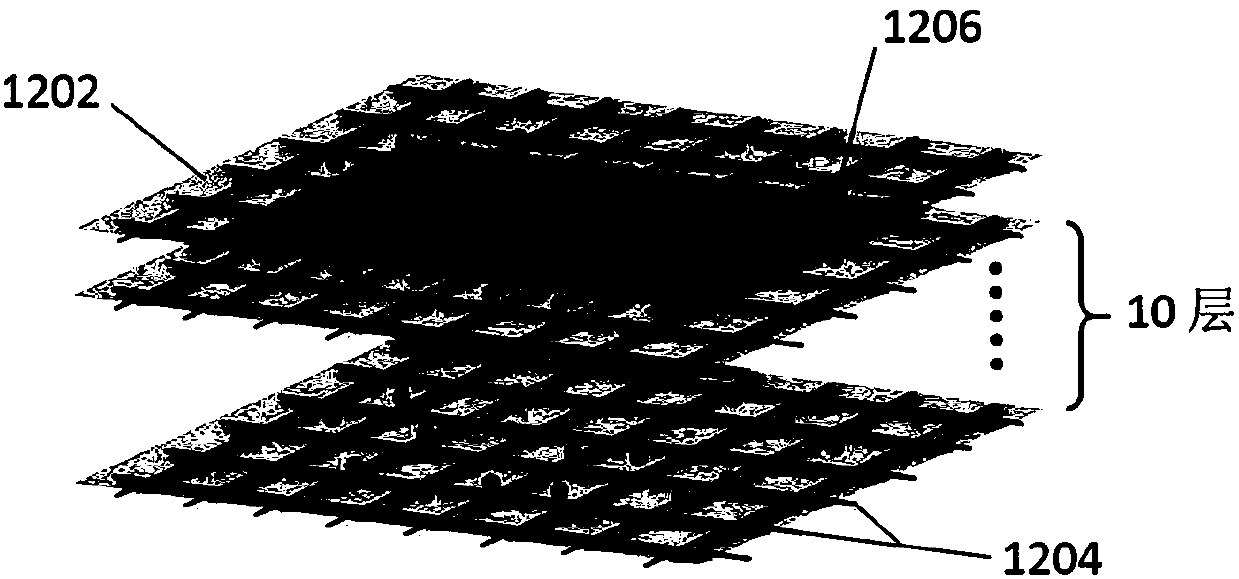

[0059] The lithium-sulfur battery diaphragm in this embodiment includes a diaphragm substrate and a functional layer, the diaphragm substrate is a polyethylene film with a thickness of 20 microns, and the functional layer includes 10 layers of graphene oxide sheets and 10 layers of carbon nanotube layers alternately arranged on the one surface of the membrane base. Multiple MnO 2 The nanoparticles are adsorbed on graphene oxide sheets, and the multiple MnO 2 Nanoparticles are embedded in the interlayer formed by the carbon nanotube layer and the graphene oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com