Battery cell, battery pole piece and preparation method thereof, battery

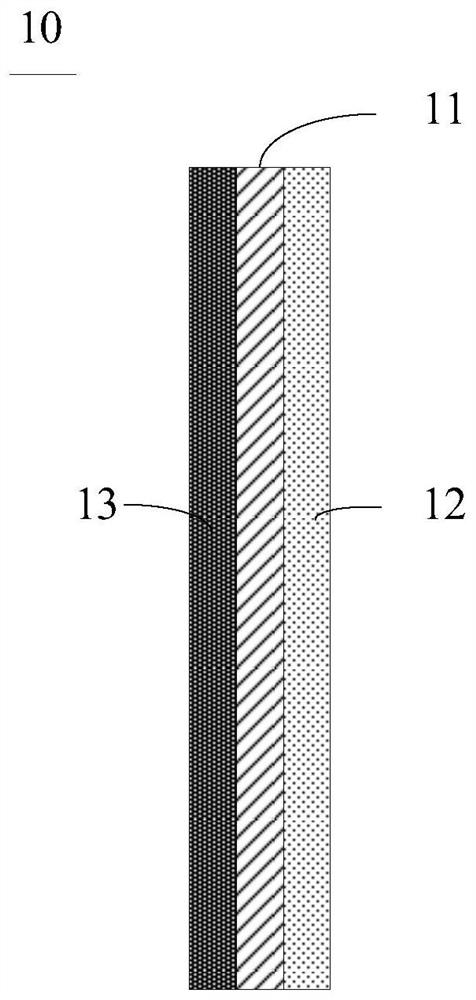

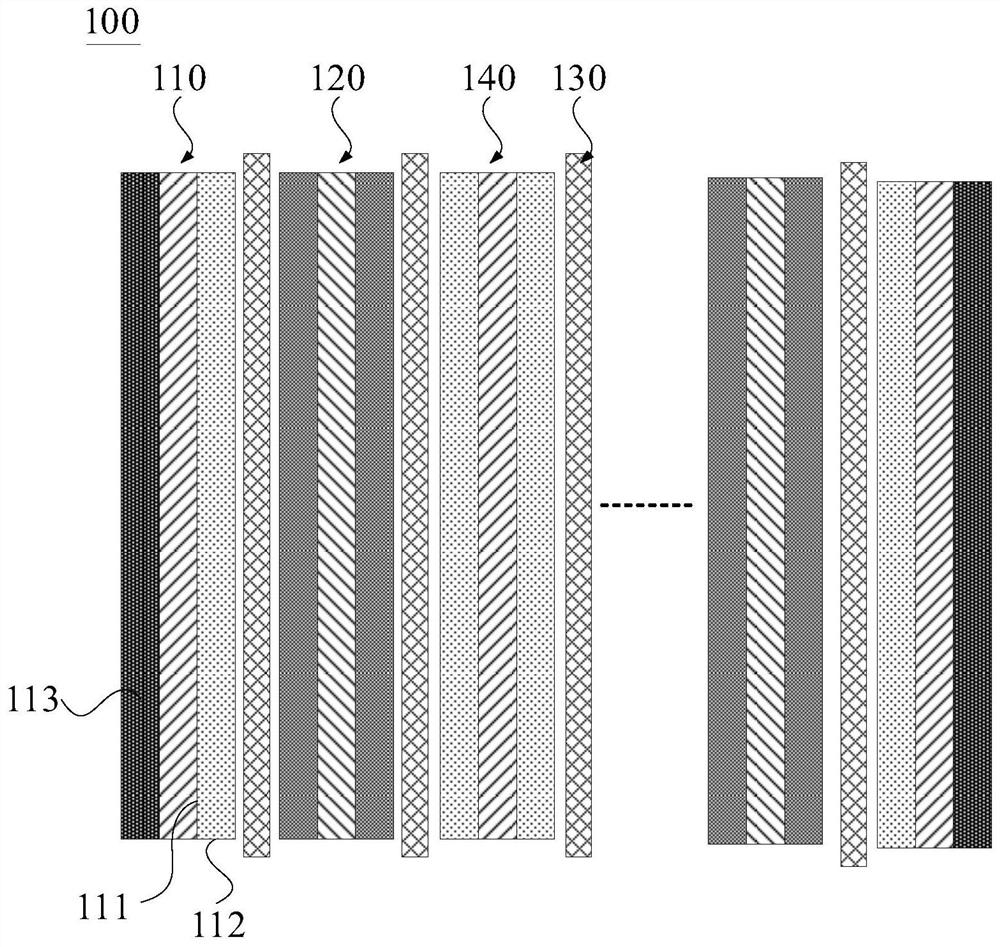

A battery cell and negative pole piece technology, applied in the field of battery pole piece and its preparation, and battery core, can solve the problems of affecting lithium ion transmission, adverse effects of battery rate performance and low temperature performance, and sacrificing battery electrochemical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

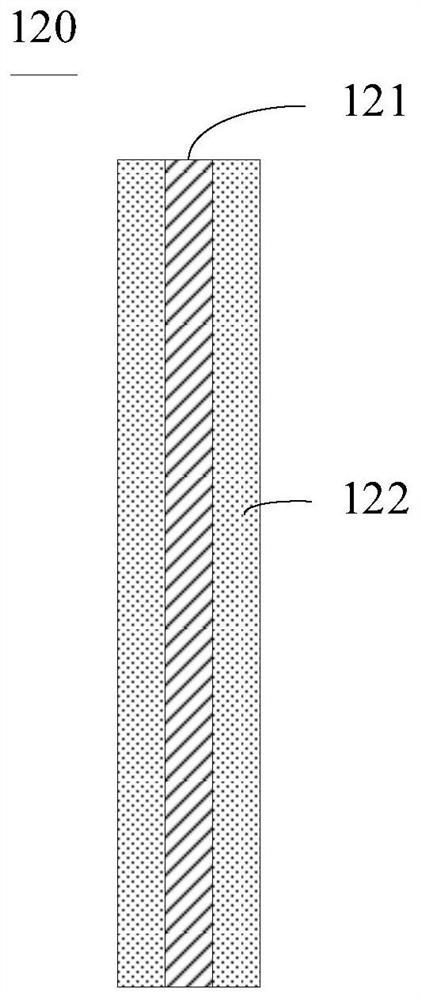

[0042] Another embodiment of the present invention provides a method for preparing the above battery pole piece, comprising the following steps:

[0043] S1. A current collector is provided.

[0044] In this specific embodiment, the current collector is copper foil. It can be understood that in other embodiments, the current collector may be a current collector made of other materials.

[0045] S2. Coating an active material coating on one surface of the current collector to form an active material coating.

[0046] In this specific embodiment, the active material coating is a negative electrode active material coating.

[0047] Specifically, graphite, conductive agent, binder and auxiliary agent are mixed, and a negative electrode active material coating is made through a homogenization process, and then a coating machine is used to coat the negative electrode active material coating on one surface of the current collector. After continuous oven drying, an active material ...

Embodiment 1

[0083] 1. Preparation of negative electrode active material coating

[0084] Add graphite, conductive carbon black, sodium carboxymethyl cellulose, water-based styrene-butadiene latex SBR and deionized water into the homogenizer mixer in batches according to the mass ratio of 91.5:6:1.2:1.3:102, and the order of addition is deionized Water, sodium carboxymethyl cellulose, conductive carbon black, graphite and water-based styrene-butadiene latex SBR, before adding graphite, rotate at 15r / min, rotate at 300r / min and stir for 300min, after adding graphite, rotate at 15r / min, rotate at 800r / min 1. Stir for 150min under the condition of vacuum degree of -85KPa. After the homogenization is completed, a uniformly dispersed negative electrode active material coating is obtained, and the coating is placed in a transfer tank, and stirred at a low speed of 15r / min, and set aside.

[0085] 2. Preparation of flame retardant coating

[0086] The inorganic flame retardant ammonium polyphosp...

Embodiment 2

[0095] Example 2 is basically the same as Example 1, except that the mass ratio of flame retardant, solvent, anti-settling agent, adhesive and surfactant in the flame-retardant coating of Example 2 is 6.5:7.7:0.05:0.05: 0.005.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com