Feed additive capable of reducing odor emission for pigs

A feed additive and odor emission technology, applied in animal feed, animal feed, application, etc., can solve problems such as poor effect, single addition, unsatisfactory deodorization effect, etc., to improve intestinal health, improve digestion and absorption efficiency, the effect of reducing the generation of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

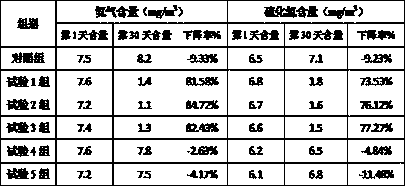

Examples

Embodiment 1

[0014] A pig feed additive capable of reducing odor emissions, characterized in that it consists of the following raw materials in parts by weight: 6 parts of refined lobster shell powder, 8 parts of poplar flowers, 7 parts of grape pomace, 9 parts of honeysuckle, 5 parts of mugwort leaves, and apple fruit 8 parts of gum oligosaccharide, 4 parts of bromelain, and the rest are carriers, and the carrier is composed of wheat flour and zeolite powder;

[0015] The preparation method of the refined lobster shell powder is as follows: wash the lobster shell, dry, crush and pass through a 60-mesh sieve to obtain the lobster shell powder, then add 10% acetic acid to the lobster shell powder according to the solid-to-liquid ratio of 1:2, and maintain Stir at 80°C for 1 hour, filter, dry the filter residue, add distilled water at a solid-to-liquid ratio of 1:4, add compound enzyme with 0.01% weight of the filter residue at the same time, adjust the pH to 5.5 with acetic acid, maintain a ...

Embodiment 2

[0019] A feed additive for pigs capable of reducing odor emissions, characterized in that it consists of the following raw materials in parts by weight: 8 parts of refined lobster shell powder, 10 parts of poplar flowers, 9 parts of grape pomace, 11 parts of honeysuckle, 7 parts of mugwort leaves, and apple fruit 11 parts of gum oligosaccharides, 6 parts of bromelain, and the rest are carriers, and the carriers are composed of wheat flour and zeolite powder;

[0020] The preparation method of the refined lobster shell powder is as follows: wash the lobster shell, dry, crush and pass through a 60-mesh sieve to obtain the lobster shell powder, then add 13% acetic acid to the lobster shell powder according to the solid-to-liquid ratio of 1:2.5, and maintain Temperature 85°C, stir for 1.5h, filter, dry the filter residue, then add distilled water according to the solid-to-liquid ratio of 1:5, add compound enzyme with 0.03% weight of the filter residue at the same time, adjust the p...

Embodiment 3

[0024] A feed additive for pigs capable of reducing odor emissions, characterized in that it consists of the following raw materials in parts by weight: 10 parts of refined lobster shell powder, 12 parts of poplar flowers, 11 parts of grape pomace, 13 parts of honeysuckle, 9 parts of mugwort leaves, and apple fruit 14 parts of gum oligosaccharides, 8 parts of bromelain, and the rest are carriers, and the carriers are composed of wheat flour and zeolite powder;

[0025] The preparation method of the refined lobster shell powder is as follows: wash the lobster shell, dry, pulverize and pass through a 60-mesh sieve to obtain the lobster shell powder, then add 15% acetic acid to the lobster shell powder according to the solid-to-liquid ratio of 1:3, and maintain Temperature at 90°C, stir for 2 hours, filter, dry the filter residue, then add distilled water at a solid-to-liquid ratio of 1:6, and at the same time add a complex enzyme with a weight of 0.04% of the filter residue, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com