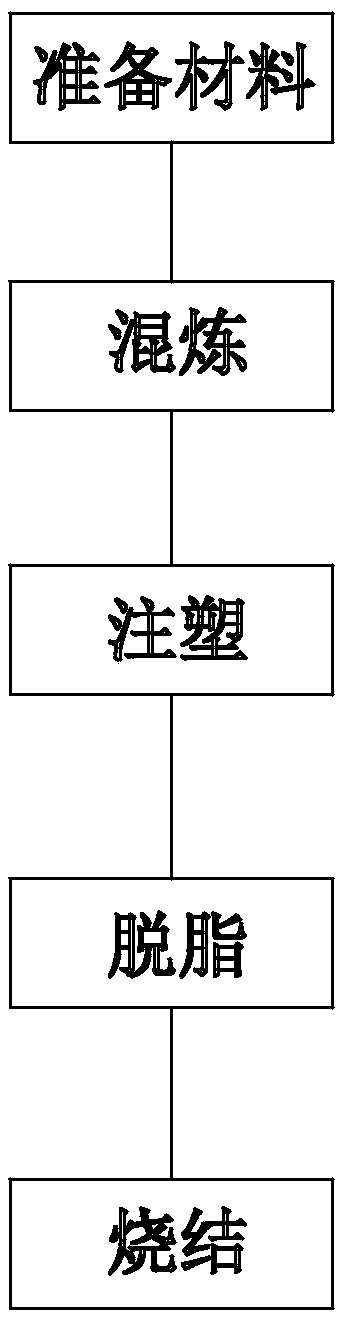

Manufacturing process of golf club head

A golf head and manufacturing process technology, which is applied to golf balls, golf clubs, metal processing equipment, etc., can solve the problems of long production cycle, high processing cost, large weight tolerance, etc., and achieve good product consistency and processing efficiency The effect of high, tight weight tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare 17-4 stainless steel powder with a particle size of D90≤22 μm, and prepare a binder, which includes polyoxymethylene resin, high-density polyethylene, ethylene-vinyl acetate copolymer, and stearic acid. The above components account for The ratio is 88:7:2:2:1. After preheating the stainless steel powder at 220°C for 15 minutes, add the adhesive. After the adhesive starts to melt, carry out banburying. After banburying for 15 minutes, cool down to 180°C and pass Screw extruded and cut into pellets; the material is extruded through the mold cavity, the amount of sol in the injection molding machine is more than 1.4 times the injection weight of the Golf ball head, the pressure during injection molding is 160mpa, the speed is 40mm / s, and the mold temperature is 85 ℃; use nitric acid to catalyze degreasing, the acid feed rate is 2g / min, and the degreasing time is 15h; vacuum sintering in a graphite furnace, the sintering temperature is 1300°C when sintering 17-4 stai...

Embodiment 2

[0034] Prepare 304 stainless steel powder with a particle size of D90≤22μm, and prepare a binder, which includes polyoxymethylene resin, high-density polyethylene, ethylene-vinyl acetate copolymer, and stearic acid. The above-mentioned components are 88:7:2:2:1, after preheating the stainless steel powder at 230°C for 15 minutes, add the binder, the binder starts to melt and then carry out banburying, after 20 minutes of banburying, cool down to 190°C and extrude through the screw Take out and cut into pellets; the material is extruded through the mold cavity, the amount of injection molding machine sol is more than 1.4 times the injection weight of the Golf ball head, the pressure during injection molding is 220mpa, the speed is 80mm / s, and the mold temperature is 95°C; Catalyzed degreasing with nitric acid, the amount of acid feed is 4g / min, and the degreasing time is 18h; Vacuum sintering in a graphite furnace, the sintering temperature is 1380°C when sintering 304 stainless...

Embodiment 3

[0036] Prepare 316 stainless steel powder with a particle size of D90≤22μm, and prepare a binder, which includes polyoxymethylene resin, high-density polyethylene, ethylene-vinyl acetate copolymer, and stearic acid. The above-mentioned components are 88:7:2:2:1, after preheating the stainless steel powder at 225°C for 15 minutes, add the binder, the binder starts to melt and then carry out banburying, after 18 minutes of banburying, cool down to 185°C and extrude through the screw Take out and cut into pellets; the material is extruded through the mold cavity, the amount of injection molding machine sol is more than 1.4 times the injection weight of the Golf ball head, the pressure during injection molding is 190mpa, the speed is 60mm / s, and the mold temperature is 90°C; Catalyzed degreasing with nitric acid, the amount of acid input is 3g / min, and the degreasing time is 16h; Vacuum sintering in graphite furnace, when sintering 316 stainless steel, the sintering temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com