Compound type desensitizing agent for pyrotechnic composition of fireworks

A fireworks and firecracker, composite technology, applied in the directions of non-explosive desensitizer/passivator, non-explosive/non-thermal agent component, explosive, etc. Deliquescence and other problems, to achieve the effect of good blasting power, strong working ability and slow burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of composite desensitizing agent for fireworks and firecrackers pyrotechnic powder, consisting of the following components in parts by weight: 40 parts of magnesium oxide, 5 parts of calcium stearate, 1 part of bismuth trioxide, bicyclic 10 parts of pentadiene iron and 5 parts of phthalic anhydride. According to the above proportions, each component is weighed and fully stirred and sieved to obtain a 120-mesh impurity-free passivator product.

Embodiment 2-5

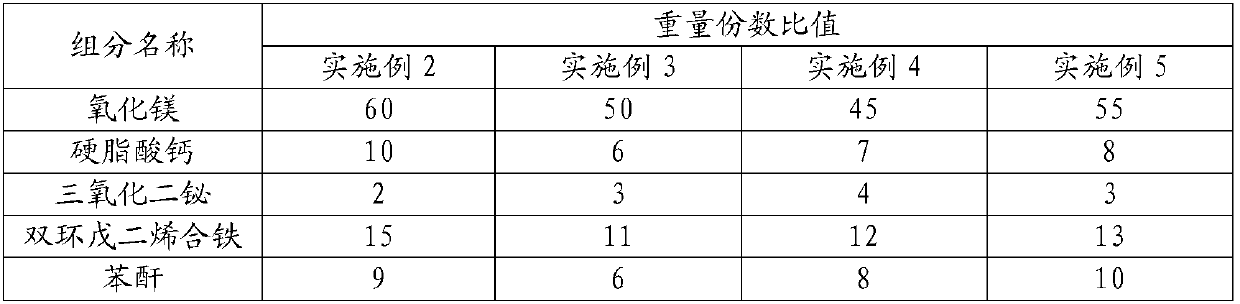

[0017] Embodiment 2-5 is different from embodiment 1 in that the proportioning of each component is different, see the following table:

[0018]

[0019] The composite desensitizers prepared in the above-mentioned embodiments can be compounded by the manufacturers themselves according to the effect requirements to obtain passivation-type fireworks and firecrackers to open explosives, propellants, and low-sensitivity, high-stability bright beads. for example:

[0020] Explosives: Prepared according to the ratio of parts by weight, composite insensitive agent: aluminum powder: potassium perchlorate = 10:10:20, and mix well according to the general method. The detonating explosive prepared with this compound desensitizing agent has the same amount of charge as the traditional detonating explosive of 3.6 g under the condition of 12 g bright beads in the inner cylinder, and the detonating width is 15-20 meters in diameter, which is up to the standard.

[0021] Propellant: Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com