Functionalization hyper-crosslinked resin and preparation method thereof

A technology of ultra-high cross-linked resin and cross-linked resin, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of reducing the degree of ultra-high cross-linking of resin and unfavorable adsorption mass transfer , Functional groups occupy the pore space and other problems, to achieve good desorption performance and good regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. This embodiment describes the preparation method of functionalized ultra-high cross-linked resin.

[0031] (1) Add 50mL of 1,2-dichloroethane and 6g of chlorine balls into a 100mL three-necked flask equipped with a stirrer and a thermometer, and swell at room temperature for 12h.

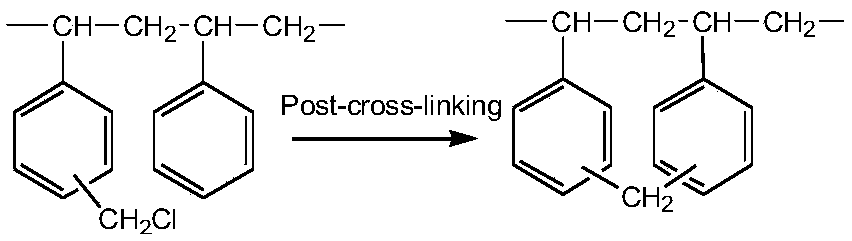

[0032] (2) Then add 1.2g of anhydrous aluminum chloride, the system is mechanically stirred at room temperature for 30 minutes, then the system is heated to 80°C within 15 to 30 minutes, and the timing is started. After 4 hours of reaction, stop the reaction, filter out the resin, and use Rinse with industrial ethanol and pure water, and then use industrial ethanol and pure water to wash 4 times under ultrasonic, 30min each time. After cleaning, the resin was moved into a blast drying oven at 70°C and dried for 12 hours to obtain a post-crosslinking resin. The post-crosslinking reaction of the resin is as follows: figure 1 shown.

[0033] (3) Take 5 g of post-crosslinking resi...

Embodiment 2

[0037] Embodiment 2. This embodiment describes the preparation method of functionalized ultra-high cross-linked resin.

[0038] (1) Add 50mL of 1,2-dichloroethane and 6g of chlorine balls into a 100mL three-necked flask equipped with a stirrer and a thermometer, and swell at room temperature for 12h.

[0039] (2) Then add 1.2g of anhydrous aluminum chloride, the system is mixed under mechanical stirring at room temperature, the temperature of the system is raised to 80 ° C, and the timing is started. After 4 hours of reaction, the reaction is stopped, the resin is filtered out, and the resin is mixed with industrial ethanol and pure water. Rinse, and then use industrial ethanol and pure water to wash 4 times under ultrasonic, each time for 30 minutes. After cleaning, the resin is moved into a 70°C blast drying oven and dried for 12 hours to obtain a post-crosslinking resin. The post-crosslinking reaction of the resin is as follows: figure 1 shown.

[0040] (3) Take 5g of post...

Embodiment 3

[0044] Embodiment 3. This embodiment describes the preparation method of functionalized ultra-high cross-linked resin.

[0045] (1) Add 50mL of 1,2-dichloroethane and 6g of chlorine balls into a 100mL three-necked flask equipped with a stirrer and a thermometer, and swell at room temperature for 12h.

[0046] (2) Then add 1.2g of anhydrous aluminum chloride, mix the system under mechanical stirring at room temperature, heat up the system to 80°C, start timing, after 4 hours of reaction, stop the reaction, filter out the resin, and use industrial ethanol and pure water Rinse, and then use industrial ethanol and pure water to wash 4 times under ultrasonic, 30min each time. After cleaning, the resin was moved into a blast drying oven at 70°C and dried for 12 hours to obtain a post-crosslinking resin. The post-crosslinking reaction of the resin is as follows: figure 1 shown.

[0047] (3) Take 5 g of post-crosslinking resin and 50 mL of dichloroethane in a 100 mL three-necked fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com