Multifunctional emulsion paint as well as preparation method and application thereof

A latex paint and emulsion technology, applied in latex paint, biocide-containing paint, conductive paint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

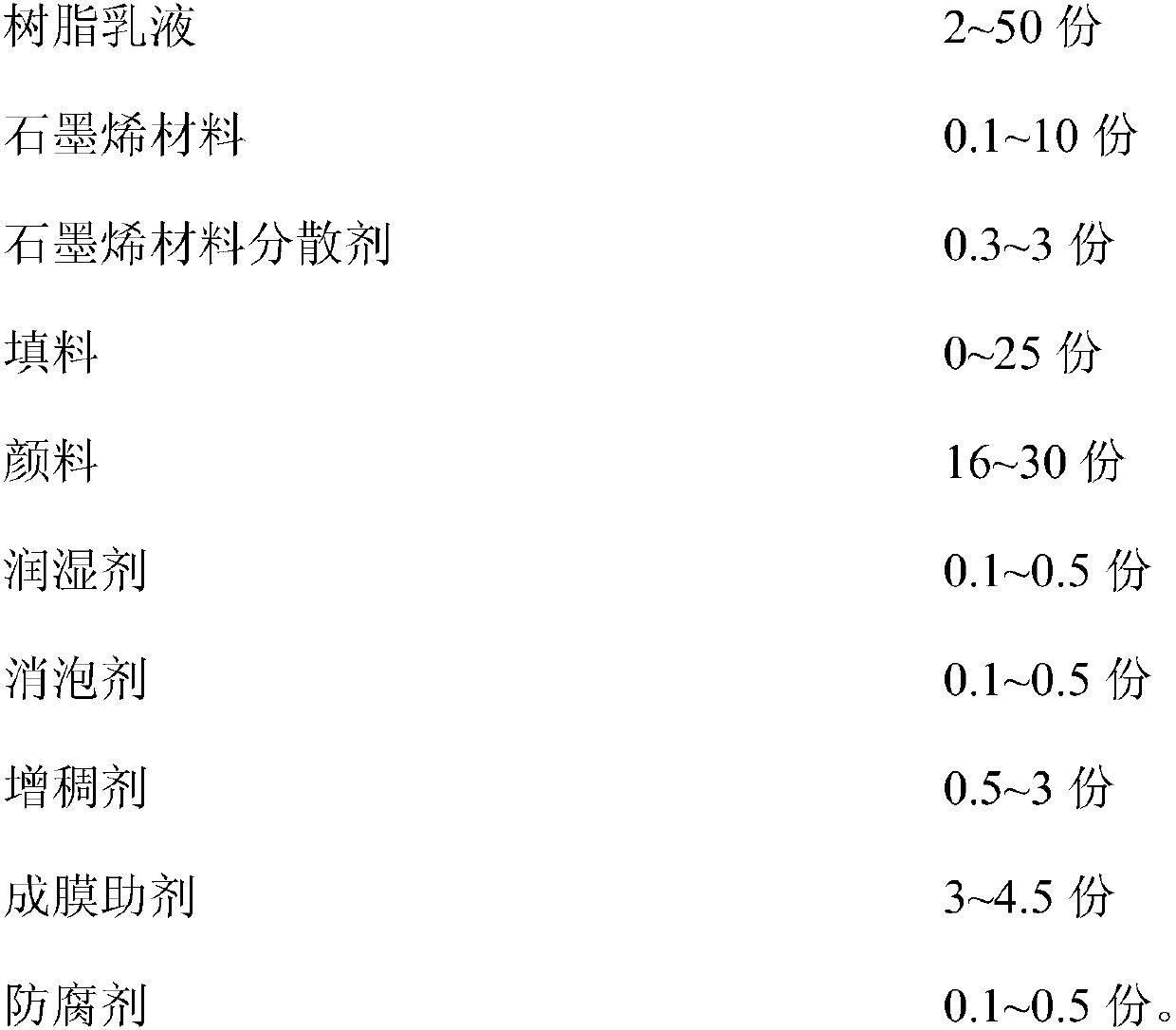

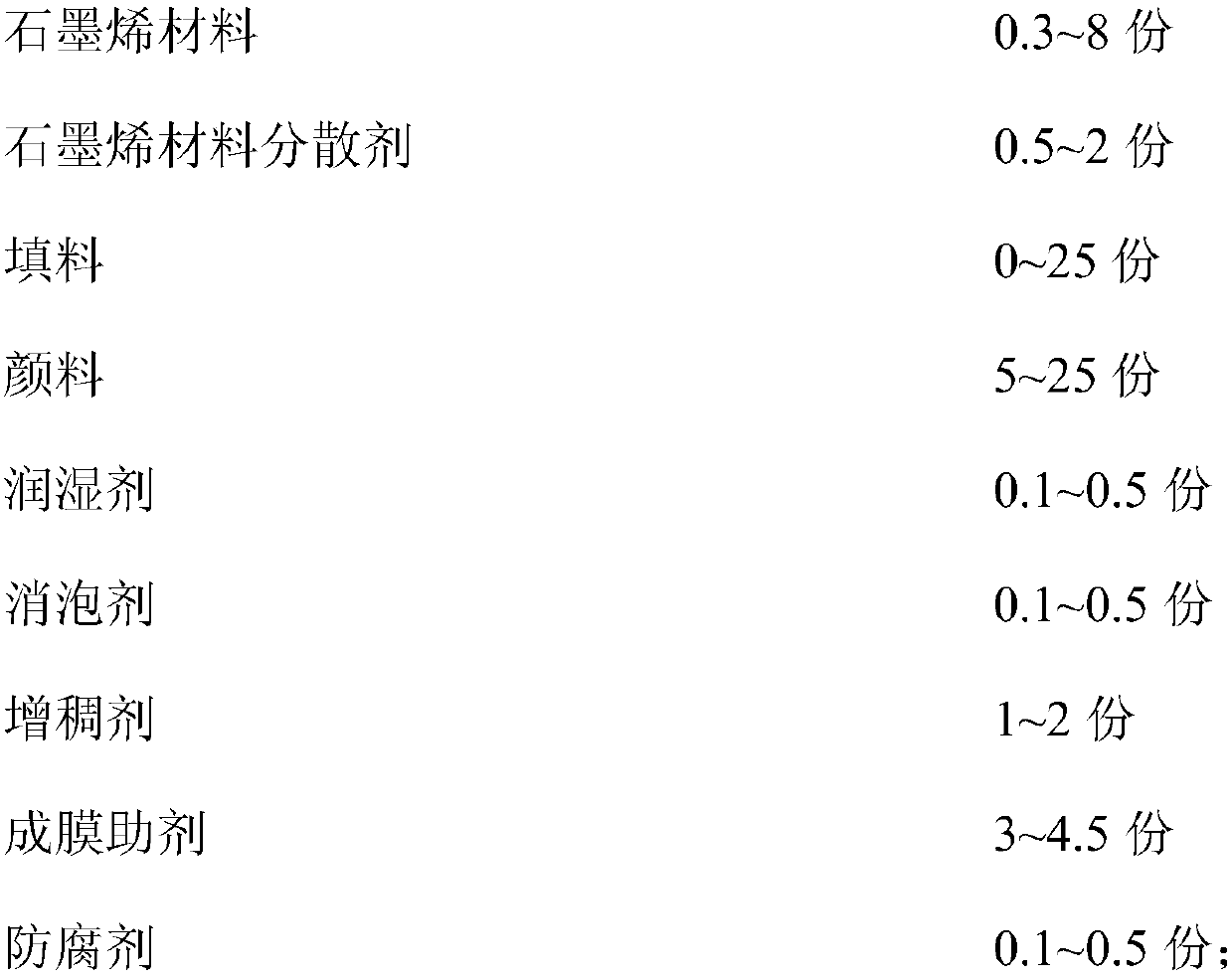

Method used

Image

Examples

Embodiment 1

[0079] A kind of preparation method of multifunctional latex paint, it comprises the steps:

[0080] (1) Mix 40.0kg acrylate emulsion, 14.0kg light calcium carbonate, 8.0kg talcum powder, 8.0kg titanium dioxide, 0.2kg wetting agent os-405, 3.5kg ethylene glycol butyl ether and 0.3kg preservative XG- 215 Mix evenly by means of strong mechanical stirring and mechanical grinding to obtain the first emulsion;

[0081] (2) 0.5kg Graphene A and 0.5kg polyvinylpyrrolidone K90 are added to 2.5kg water, Graphene material is dispersed in water, obtains Graphene material predispersion;

[0082] (3) 74.0kg first emulsion and 3.5kg graphene material pre-dispersion liquid, 2.5kg hydroxyethyl cellulose, 0.5kg polyoxyethylene polyoxypropylene pentaerythritol ether, 20.0kg pigment are fully mixed to obtain multifunctional latex paint anticipation ;

[0083] (4) filter the multifunctional latex paint and expect to obtain the multifunctional latex paint.

Embodiment 2

[0085] (1) Mix 40.0kg acrylate emulsion, 14.0kg light calcium carbonate, 8.0kg talcum powder, 8.0kg titanium dioxide, 0.2kg wetting agent os-405, 3.5kg ethylene glycol butyl ether and 0.3kg preservative XG- 215 Mix evenly by means of strong mechanical stirring and mechanical grinding to obtain the first emulsion;

[0086] (2) 1.0kg Graphene C and 0.5kg polyvinylpyrrolidone K90 are added to 2.5kg water, Graphene material is dispersed in water, obtains Graphene material predispersion;

[0087] (3) 74.0kg first emulsion and 3.5kg graphene material pre-dispersion liquid, 2.5kg hydroxyethyl cellulose, 0.5kg polyoxyethylene polyoxypropylene pentaerythritol ether, 20.0kg pigment are fully mixed to obtain multifunctional latex paint anticipation ;

[0088] (4) filter the multifunctional latex paint and expect to obtain the multifunctional latex paint.

Embodiment 3

[0090] (1) Mix 40.0kg acrylate emulsion, 14.0kg light calcium carbonate, 8.0kg talcum powder, 8.0kg titanium dioxide, 0.2kg wetting agent os-405, 3.5kg ethylene glycol butyl ether and 0.3kg preservative XG- 215 Mix evenly by means of strong mechanical stirring and mechanical grinding to obtain the first emulsion;

[0091] (2) 2.0kg Graphene A and 0.5kg polyvinylpyrrolidone K90 are added to 2.5kg water, Graphene material is dispersed in water, obtains Graphene material predispersion;

[0092] (3) the first emulsion of 74.0kg and 3.5kg polyvinylpyrrolidone K90, 2.5kg hydroxyethyl cellulose, 0.5kg polyoxyethylene polyoxypropylene pentaerythritol ether, 20.0kg pigment are fully mixed to obtain multifunctional latex paint;

[0093] (4) filter the multifunctional latex paint and expect to obtain the multifunctional latex paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com