New energy material for motor vehicles, and applications thereof

A technology for new energy materials and motor vehicles, applied in the field of energy and chemical industry, can solve the problems of long charging time, energy exhaustion, short cruising range, etc., and achieve the effects of simple and easy preparation method, cost reduction, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

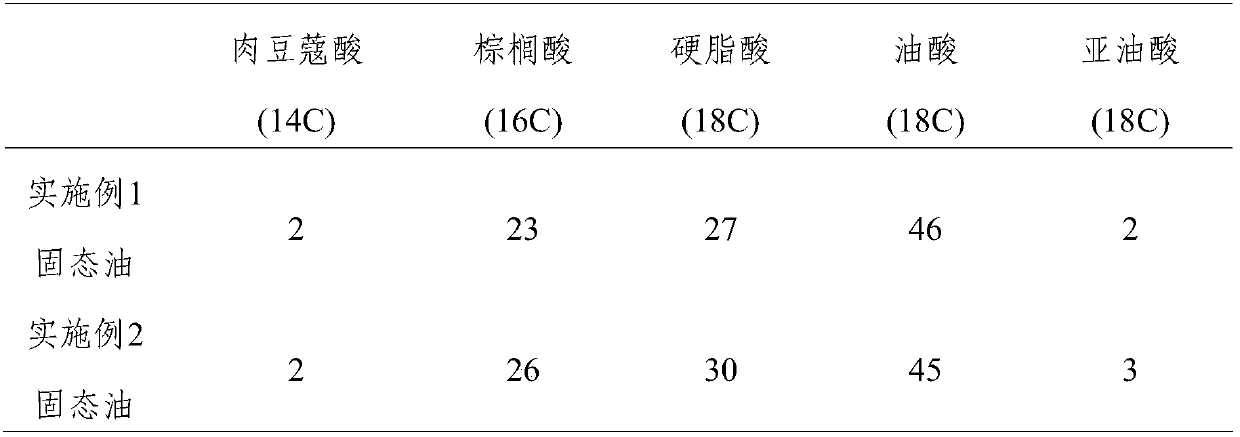

[0021] Example 1 Preparation of new energy materials for motor vehicles

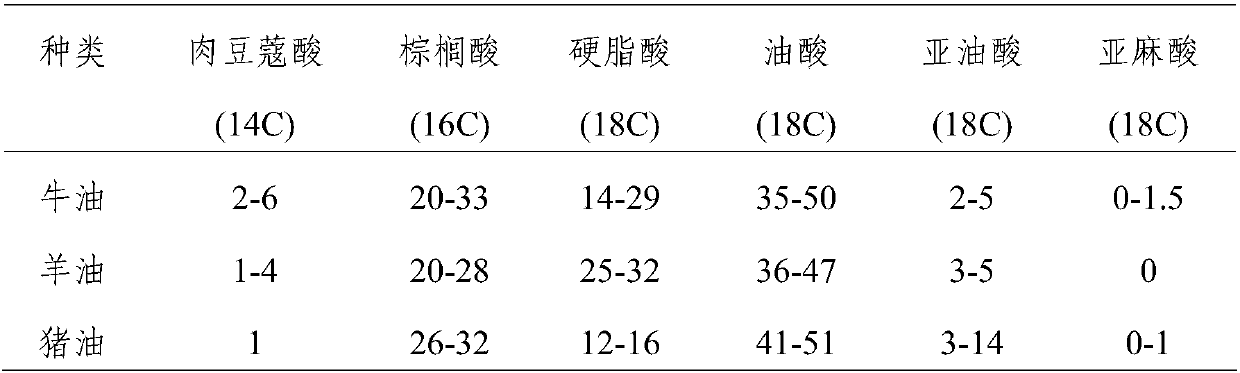

[0022] Take beef suet 5000g, add in the reactor after chopping, add 25000mL damping fluid to dissolve then, add catalyzer---hormone-sensitive lipase 25g (enzyme activity 400-900U / mg) of bovine in reactor again, at 37 The reaction was carried out at ℃ for hydrolysis reaction, the reaction time was 24h, centrifuged, the water phase was removed, and cooled to room temperature to obtain a mixture of fatty acids (mainly including myristic acid, palmitic acid, stearic acid, oleic acid, linoleic acid, etc.) and glycerin.

[0023] Gained solid oil is equipped with certain catalyst or ignition agent, for example adds gasoline (gasoline heat value is 4.6 * 10 by 10% of described solid oil weight) 7 J / Kg), used for the energy of motor vehicles such as automobiles and tractors.

Embodiment 2

[0024] Example 2 Preparation of new energy materials for motor vehicles

[0025] Weigh 3000g of sheep suet, chop it up and add it to the reactor, then add 15000mL of water to dissolve it, and then add the catalyst—15g of sheep hormone-sensitive lipase (enzyme activity 350-830U / mg) to the reactor, at 37°C The next step is to carry out the hydrolysis reaction, the reaction time is 22h, centrifuge, remove the water phase, and cool to room temperature to obtain a mixture of fatty acids (mainly including palmitic acid, stearic acid, oleic acid, linoleic acid, etc.) and glycerin.

[0026] The obtained solid oil is matched with a certain catalyst or igniter, for example, industrial ethanol is added according to 10% of the weight of the solid oil, and used for the energy source of motor vehicles such as automobiles and tractors.

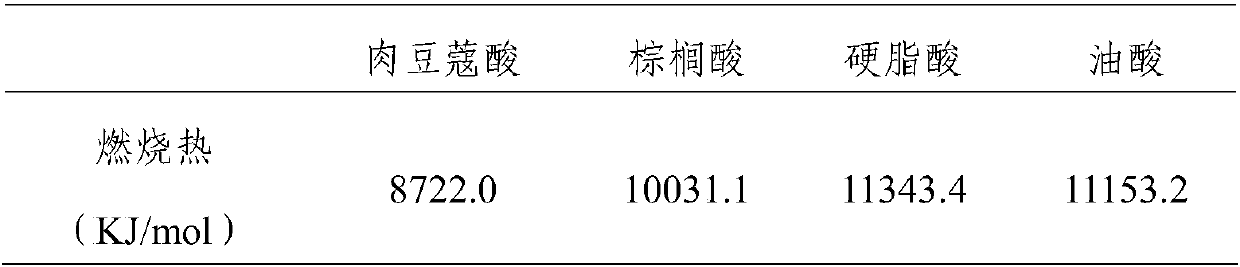

[0027] Table 2 shows the combustion calorific values of several fatty acids with relatively high content in the solid oil prepared in Examples 1 and 2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com