Segmented laser light source system

A laser light source, segmented technology, used in optics, optical components, instruments, etc., can solve problems such as uneven speckle effect, achieve good engineering achievability, reduce overall size, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

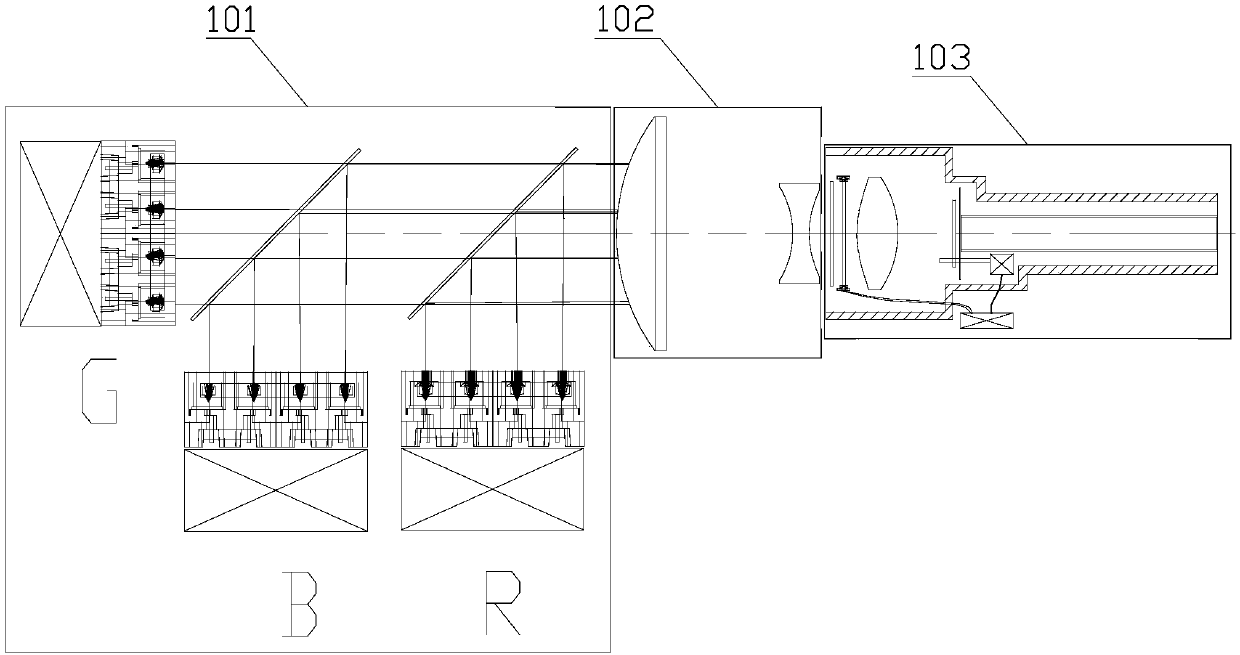

[0032] Such as figure 1 As shown, Embodiment 1 provides a segmented laser light source system, including a semiconductor laser light source 101, a telescopic beam reduction system 102, and a laser speckle extinction-homogenizer 103;

[0033] Such as figure 1 with figure 2 As shown, the semiconductor laser light source 101 includes an RGB diode array module, an array collimator lens, and a beam splitter. Dynamic diffusion wheel 204 , open-type shading plate 205 , homogenizing light guide rod 206 , mechanism housing 207 , and drive control board 208 .

[0034] The working principle of Embodiment 1 is: the RGB diode array modules output the laser light field in parallel through their corresponding array collimating lenses, and the laser light field is coupled into a laser light field with a common aperture through the beam splitter, and enters the telescopic beam reduction system 102 The telephoto beam reduction system 102 compresses the aperture of the laser light field, and...

Embodiment 2

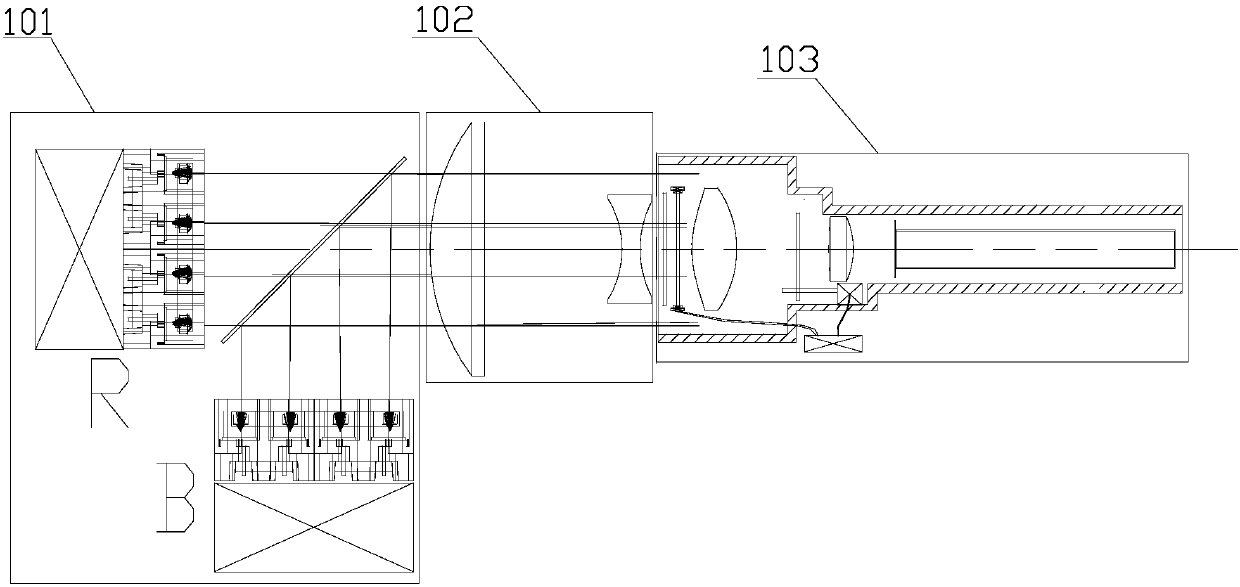

[0050] Such as image 3 As shown, Embodiment 2 provides a segmented laser light source system, including blue and red semiconductor laser light sources, a telescopic beam reduction system, and a laser speckle-dissipating homogenizer.

[0051] In this example, the blue and red semiconductor laser light sources include RB diode array module, array collimator lens, and beam splitter. The RB diode array module includes RB laser diode array, thermal copper plate, heat pipe, and heat sink; Arranged and installed on the respective heat-conducting copper plates. The heat-conducting copper plates are inserted with heat-conducting tubes. The heat-conducting tubes contain refrigerant. The arrangement and layout are consistent with the laser diode array, forming a one-to-one correspondence.

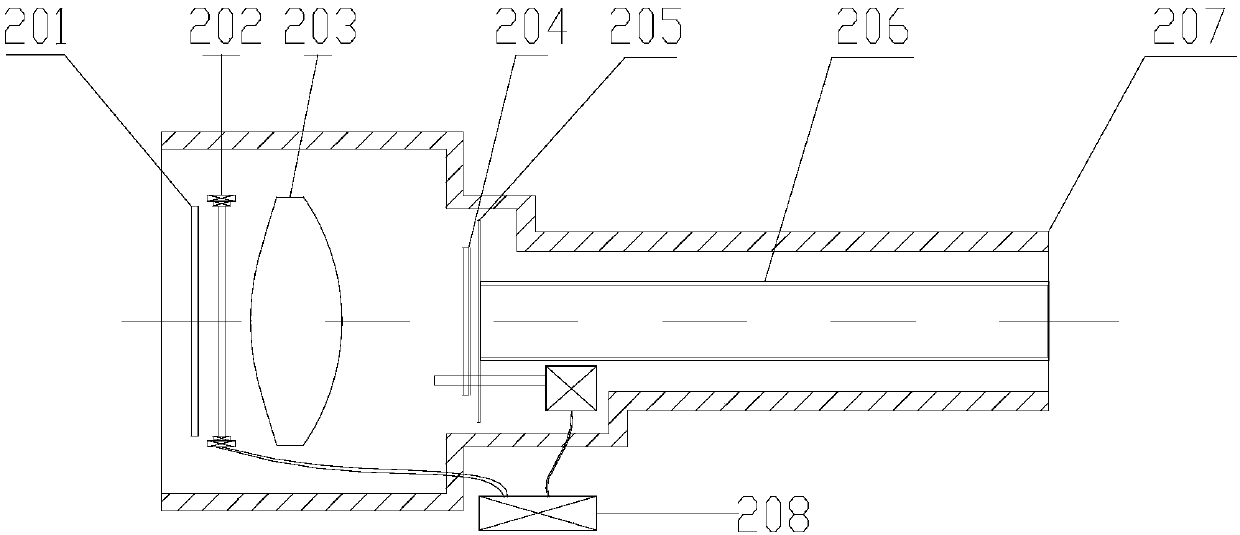

[0052] Similar to Example 1, the laser speckle dissipation-homogenizer in Example 2 includes a static diffuser 201, a phase adjuster 202, a condenser lens 203, an integrated fluorescence-filter whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com