Intelligent control system

A technology of control system and control cabinet, which is applied in the direction of general control system, control/regulation system, program control, etc., which can solve the problems of waste of resources, time-consuming and labor-intensive, and failure to achieve the degree of automation, so as to reduce labor intensity and realize remote control , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

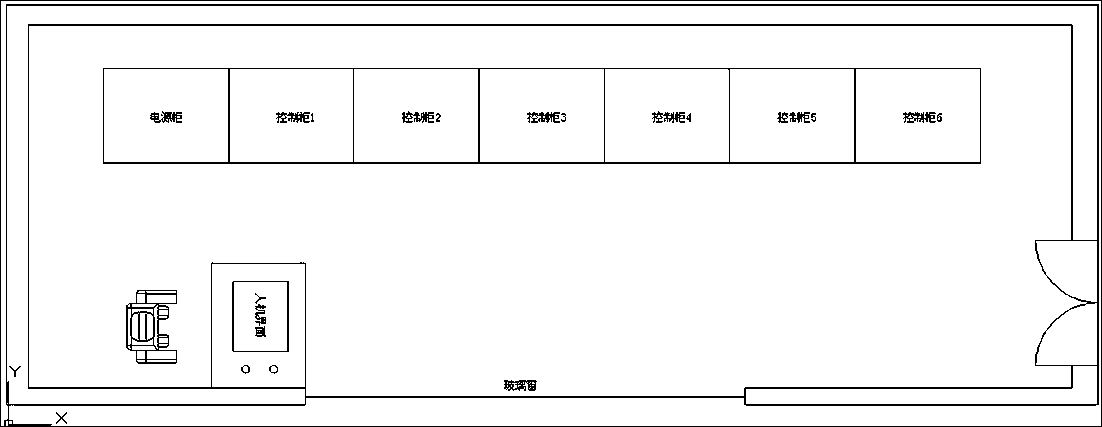

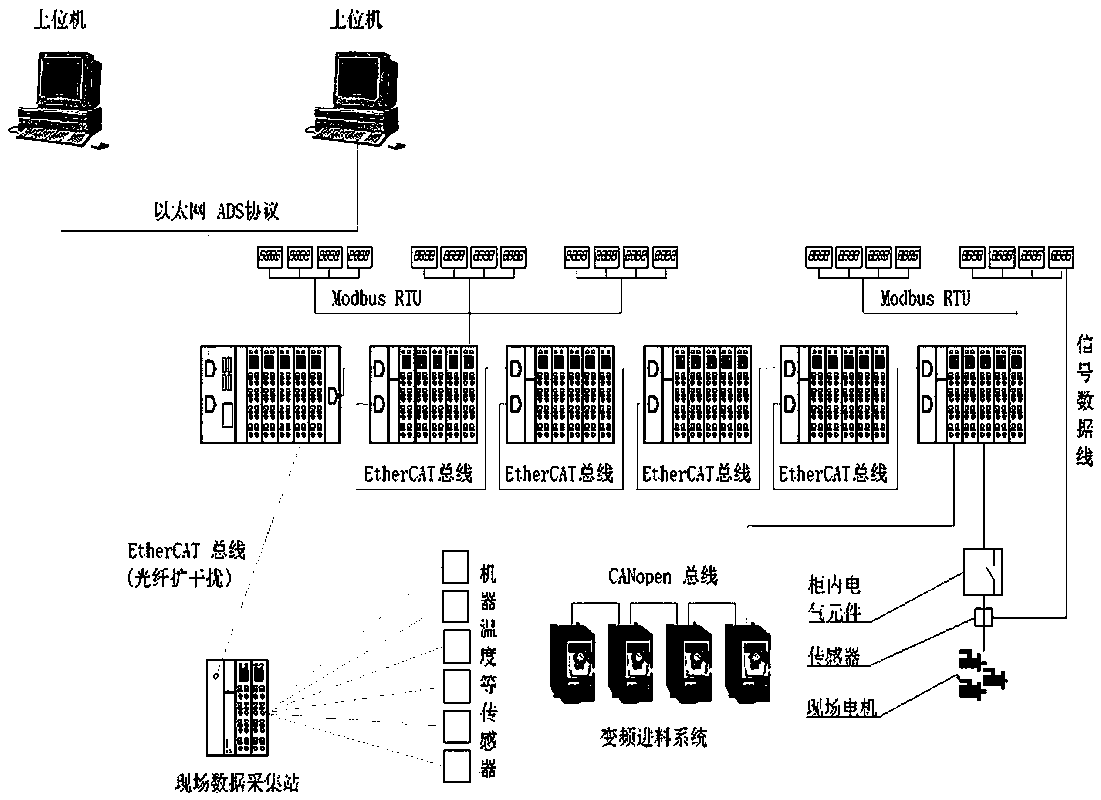

[0023] The intelligent control system provided by the present invention will be further described in conjunction with the accompanying drawings.

[0024] like Figure 1-2 As shown, the intelligent control system of waste tire processing equipment adopts high-performance PC produced by German BECKHOFF Company, and TwinCAT under WindowsNT (CE / ×P / 7) communicates with peripheral equipment through EtherCAT high-speed field bus, realizing a high-speed, efficient and stable control platform. The high-definition large-screen liquid crystal display device monitors the operating status of the device in real time through the full high-definition digital interface and modifies the device parameters online, providing users with an automatic control system with a compact structure, easy operation and maintenance, and realizing the humanized design concept.

[0025] Its working principle is: the control system uses a high-performance industrial PC as the upper computer, and a corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com