A drawing type inertial friction welding method and device

A friction welding and drawing technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of poor welding quality stability, difficult manufacturing and processing, complex process parameters, etc., and achieve short welding time and improved Good mechanical properties and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

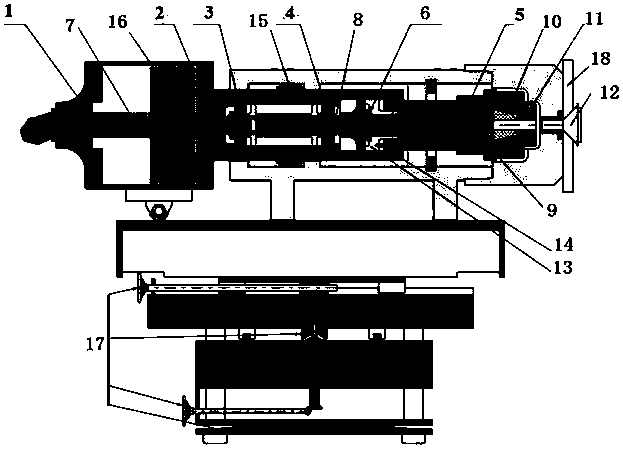

[0074] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0075] The invention discloses a pull-type inertial friction plug repair welding method, which is applied to repair welding of defects in storage tanks of spacecraft, and includes the following steps:

[0076] (1) Preparation before welding

[0077] (1.1) Joint design and processing

[0078] Make a plug hole matching the welding position of the stopper rod at the welding defect of the storage tank by machining, and process the stopper rod;

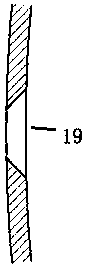

[0079] Such as figure 2 As shown, the plug hole is a tapered hole structure, and its cone angle is 40-90°. The diameter of the small end of the plug hole is set as D1, and the diameter of the large end is D2;

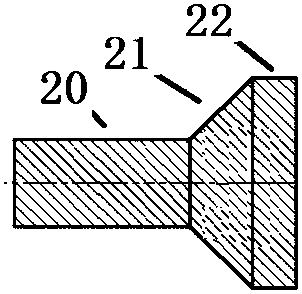

[0080] Replace defective welds with stoppers such as image 3 As shown, the stopper rod includes three coaxial parts, which are clamping section, welding section 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com