Equipment for treating wastewater with hypophosphite and phosphite

A phosphite and wastewater treatment technology, which is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of large amount of sludge generated in the system, poor chemical mixing effect, increased chemical consumption and sludge Production volume and other issues, to achieve the effect of reducing chemical consumption and sludge production, small sludge production, and reduced sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the present invention will be described in detail with reference to the drawings. Hereinafter, the same symbol is used for the same member.

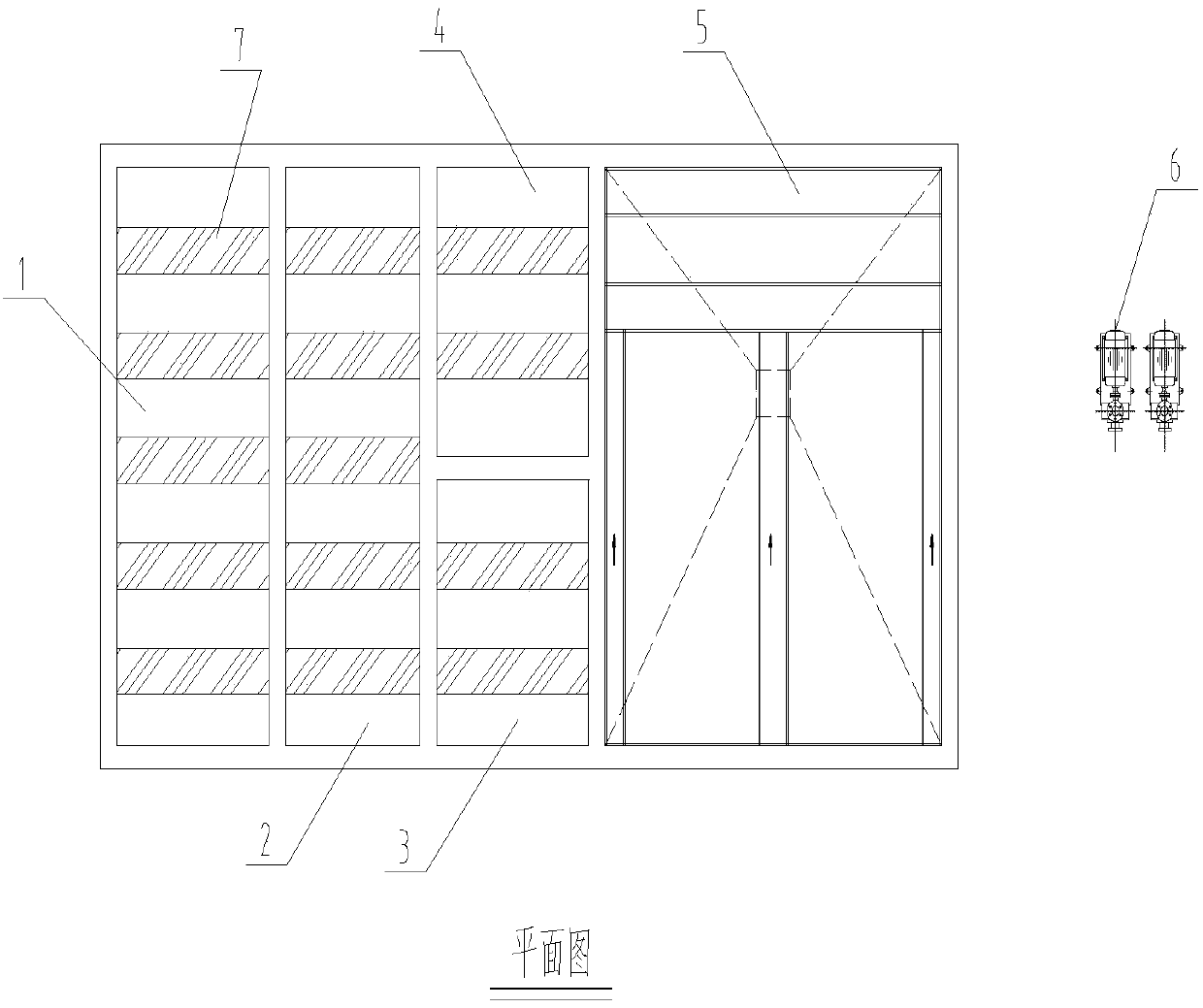

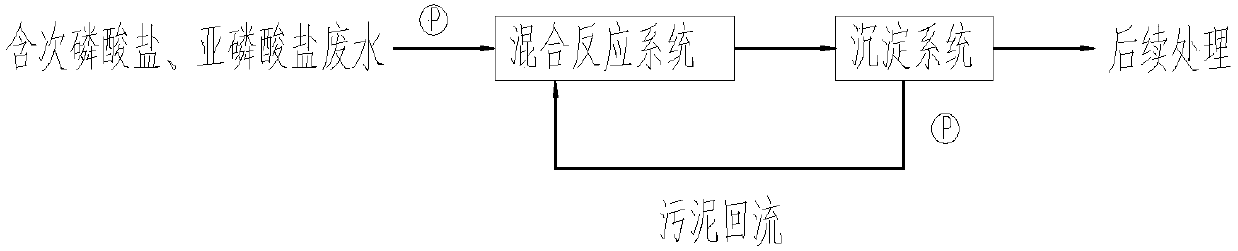

[0013] Such as figure 1 Shown, the present invention provides containing hypophosphite, phosphite waste water treatment equipment, and described equipment is made up of mixed reaction system and sedimentation system, and described mixed reaction system is used for adding Fenton medicament and coagulant, oxidizes hypophosphorous acid Salt and phosphite pollutants are used to generate calcium orthophosphate suspensions, which are beneficial to subsequent precipitation removal. The first Fenton reaction tank (1), the second Fenton reaction tank (2), the coagulation reaction tank (3), and the flocculation reaction Pool (4) and folded plate (7), described settling system is used for gravity separation calcium orthophosphate precipitate, removes total phosphorus pollution, backflow part sludge to the first Fenton reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com