Composite low-aluminum lattice brick and production method thereof

A composite type, checkered brick technology, applied in the field of refractory materials for large coke ovens, can solve the problems of reduced content, influence on use, easy cracking of checkered bricks, etc., and achieves low porosity, improved service life, and good resistance to rapid cooling and rapid heating. and anti-alkaline attack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

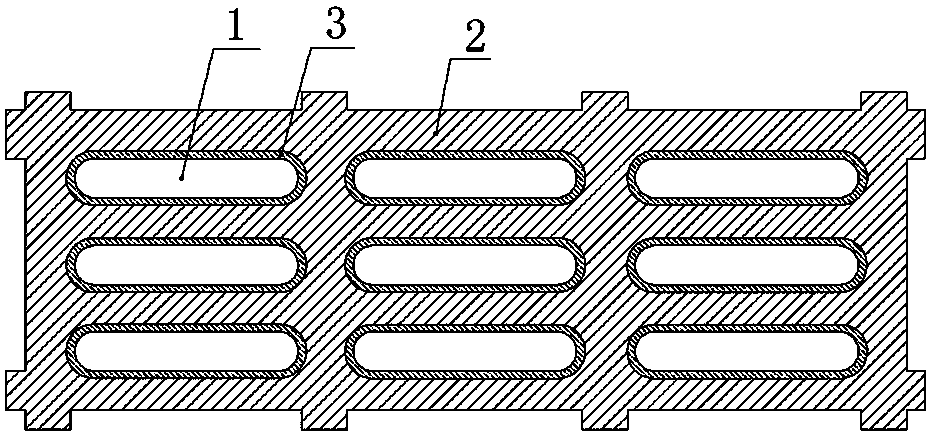

[0027] like figure 1 As shown, the composite low-aluminum checker brick of the present invention includes a clay brick base 2 with a plurality of airflow channels 1, and a high silicon coating layer 3 is compounded on the inner wall of the airflow channel 1.

[0028] The present invention will be described in more detail below through specific examples.

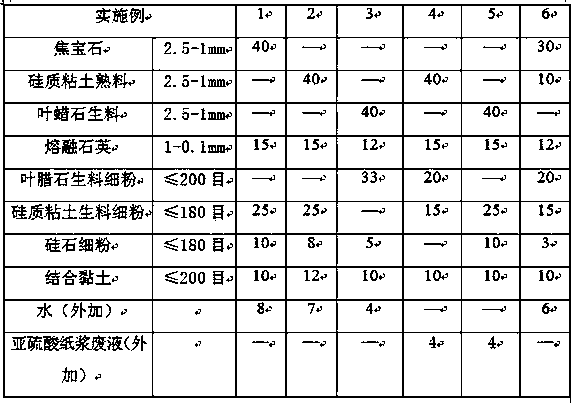

[0029] The following table 1 is the raw material composition (by weight percentage) of the clay brick matrix 2 in Examples 1-6:

[0030] Table 1

[0031]

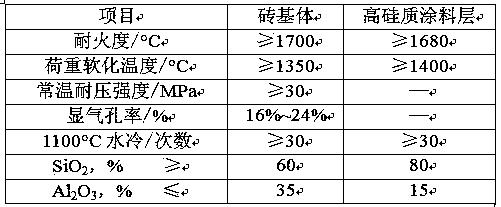

[0032] The following table 2 is the raw material composition (by weight percentage) of the high siliceous coating layer 3 in the embodiment 1~6:

[0033] Table 2

[0034]

[0035] The production method of composite low-aluminum checker brick of the present invention comprises the following steps (the production method of embodiment 1~6 is identical):

[0036] The first step, the preparation of adobe

[0037] Accurately weigh each raw material according to the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com