Envelope sustained-release fertilizer containing organic matter double-layer coating and preparation technology of envelope sustained-release fertilizer

A technology of controlled release fertilizer and preparation process, applied in the field of slow and controlled release fertilizer, can solve the problems of slow fertilizer effect, high cost of coating material, and high price of slow and controlled release fertilizer, and achieves advantages in price, strong slow release and structure. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

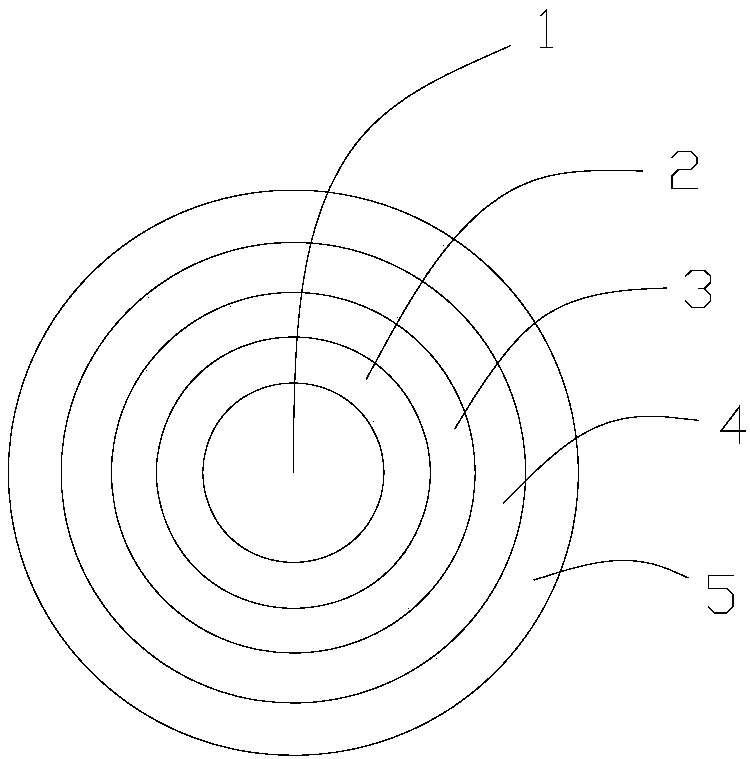

Image

Examples

Embodiment 1

[0034] Take 230g of urea (particle size between 2mm-3mm), pour it into BY-300 coating machine, spray 10mL of internal binder: 8% polyvinyl alcohol solution on the rotating urea with spray gun, Add a small amount of 40g fermented distiller's grains for many times-slightly shake and put into the sample sieve of the material, so that the material powder is evenly scattered on the surface of the rotating wet urea particles, and is adhered by the binder on the surface of the urea particles. When the surface of the urea particles is no longer wet, spray the external binder and add wrapping materials. This is repeated several times until the binder and lees are all used up. After the coating process is completed, take out the coated urea particles.

[0035] Control the coating temperature at 60-80°C, mix 9g of rosin and 6g of paraffin, add to the coating drum to melt. Then put the urea that has wrapped the inner coating material layer into the coating drum, and add a certain amount of...

Embodiment 2

[0038] Take 220g of urea (2mm-3mm), pour it into BY-300 coating machine, spray the inner binder in the form of mist with a spray gun on the rotating urea: 10mL of 8% polyvinyl alcohol solution, add 40g in small amounts several times Fermented distiller's grains: Slightly shake the sample sieve into the material, so that the material powder is evenly scattered on the surface of the rotating wet urea particles, and is adhered by the binder on the surface of the urea particles. When it is rotated, the surface of the urea particles is no longer wet. After the coating is completed, take out the urea particles.

[0039] Control the coating temperature at 60-80°C, mix 9g of rosin and 6g of paraffin, add to the coating drum to melt. Then put the urea wrapped in the inner film into the coating drum, and add a certain amount of outer film material: 180g oyster powder, stir evenly, turn off the heating, and then turn on the speed button to start the coating drum. Rotate, and after 40-50 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com