Lateral power device with mixed conduction mode and method of making same

A lateral power device and mode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electro-solid devices, etc., can solve the problems of low on-state voltage drop, reduced device loss characteristics, large turn-off loss, etc. Manufacturing difficulty, reducing turn-off loss, and improving the effect of breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

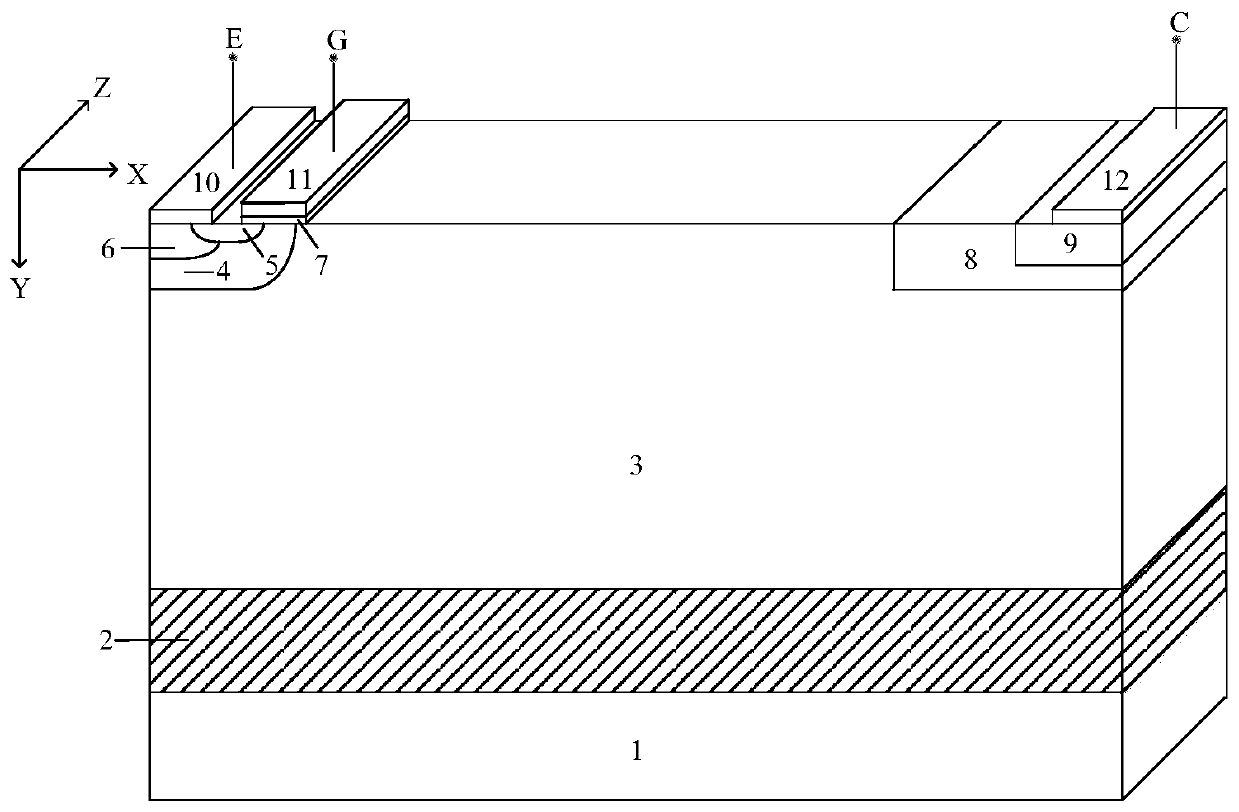

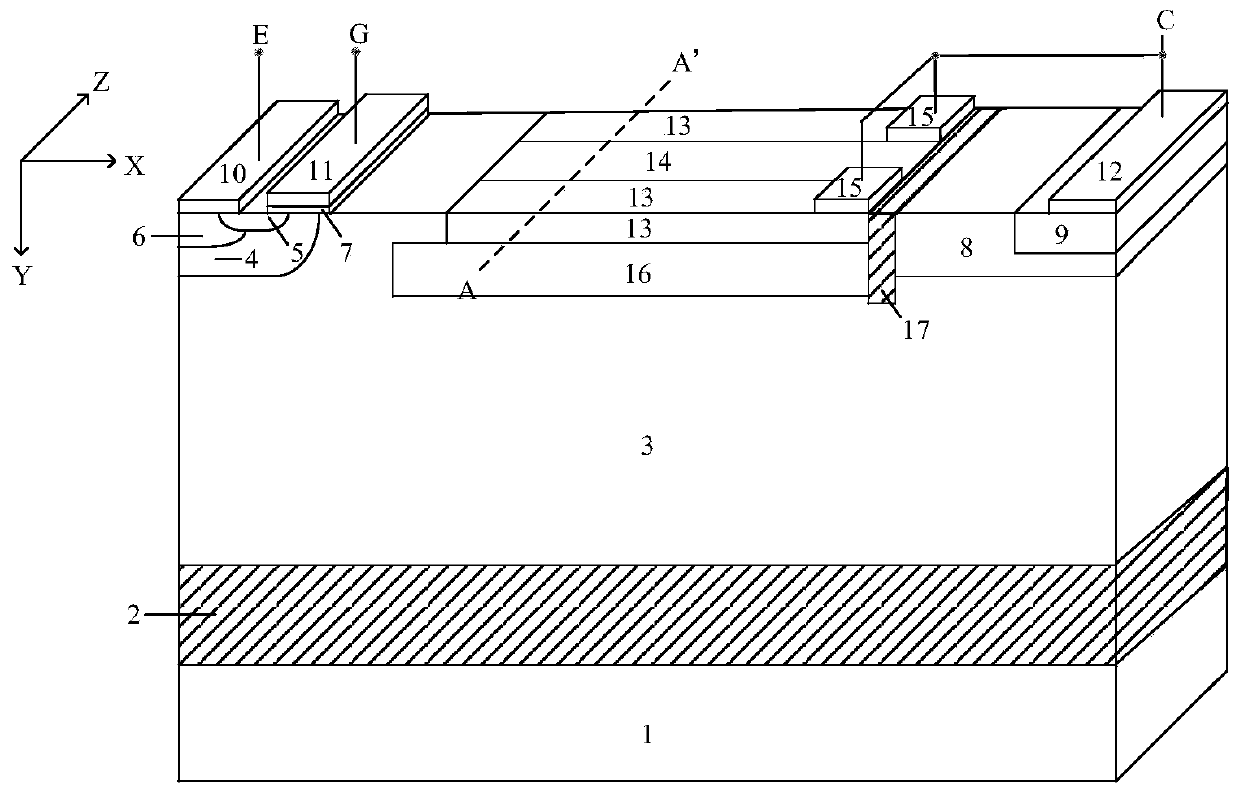

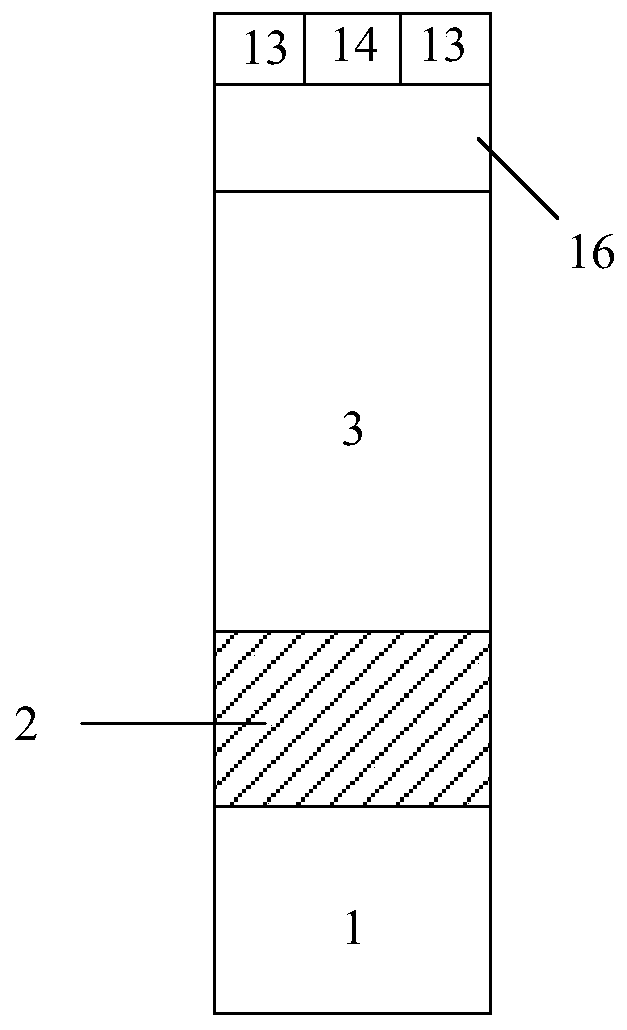

[0041] A transverse power device with mixed conduction mode, the cell structure and the cross-sectional view along line AA’ are as follows: figure 2 and image 3 As shown, it includes a P-type substrate 1, a buried oxide layer 2, and an N-type drift region 3 arranged in order from bottom to top; one end of the N-type drift region 3 is provided with a P-type base region 4, and the other end is provided with an N-type Buffer area 8; the P-type base region 4 is provided with an N-type source region 5 and a P-type contact region 6 above the interior, and the N-type buffer region 8 is provided with a P-type collector region 9 above the interior; the P-type contact There is an emitter 10 above the region 6 and part of the N-type source region 5; a part of the upper surface of the P-type collector region 9 has a collector 12; a gate dielectric layer 7 is also provided above the P-type base region 4. There is a gate electrode 11 above the dielectric layer 7. The length of the gate stru...

Embodiment 2

[0050] Such as Figure 4 with Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that there is an N-type layer 18 between the N-type strip 13, P-type strip 14 and the P-type RESURF layer 16, and the concentration of the N-type layer 18 is greater than The concentration of the N-type drift region 3. Compared with Embodiment 1, this embodiment can further improve the current conduction capability of the lateral MOSFET.

Embodiment 3

[0052] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the P-type RESURF layer 16 is composed of a first sub-region 161, a second sub-region 162, and a third sub-region 163 whose concentrations decrease from left to right. Compared with Embodiment 1, this embodiment can further increase the breakdown voltage of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com