Polyester-polyether temperature-sensitive gel with slow release of batimastat and preparation method thereof

A sustained-release preparation, batimastat technology, applied in pharmaceutical formulations, aerosol delivery, liquid delivery, etc., can solve problems such as poor oral bioavailability and inconvenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]30g of polyethylene glycol (Mn 1500) was dewatered under vacuum at 120°C for 4 hours in an oil bath, and after the temperature dropped to 80°C, under the protection of argon, according to the designed polylactide-glycolide (PLGA) terminal molecular weight and LA / GA ratio, add the calculated amount of glycolide (GA) and lactide (LA), and continue vacuuming to remove water for 15 minutes. Add stannous octoate (w / w, 30 mg / mL anhydrous toluene solution) with 0.15% monomer weight, and remove toluene by vacuuming at 80°C. The temperature of the oil bath was raised to 150°C for 12 hours. After the reaction was completed, the temperature was lowered to 120° C., and vacuum was applied for 2 hours. Pour the reaction product into hot water at 80°C while it is hot, stir and wash it thoroughly, let it stand for 10 minutes, discard the upper liquid, and freeze-dry the solid viscous precipitate at the bottom to obtain the product.

Embodiment 2

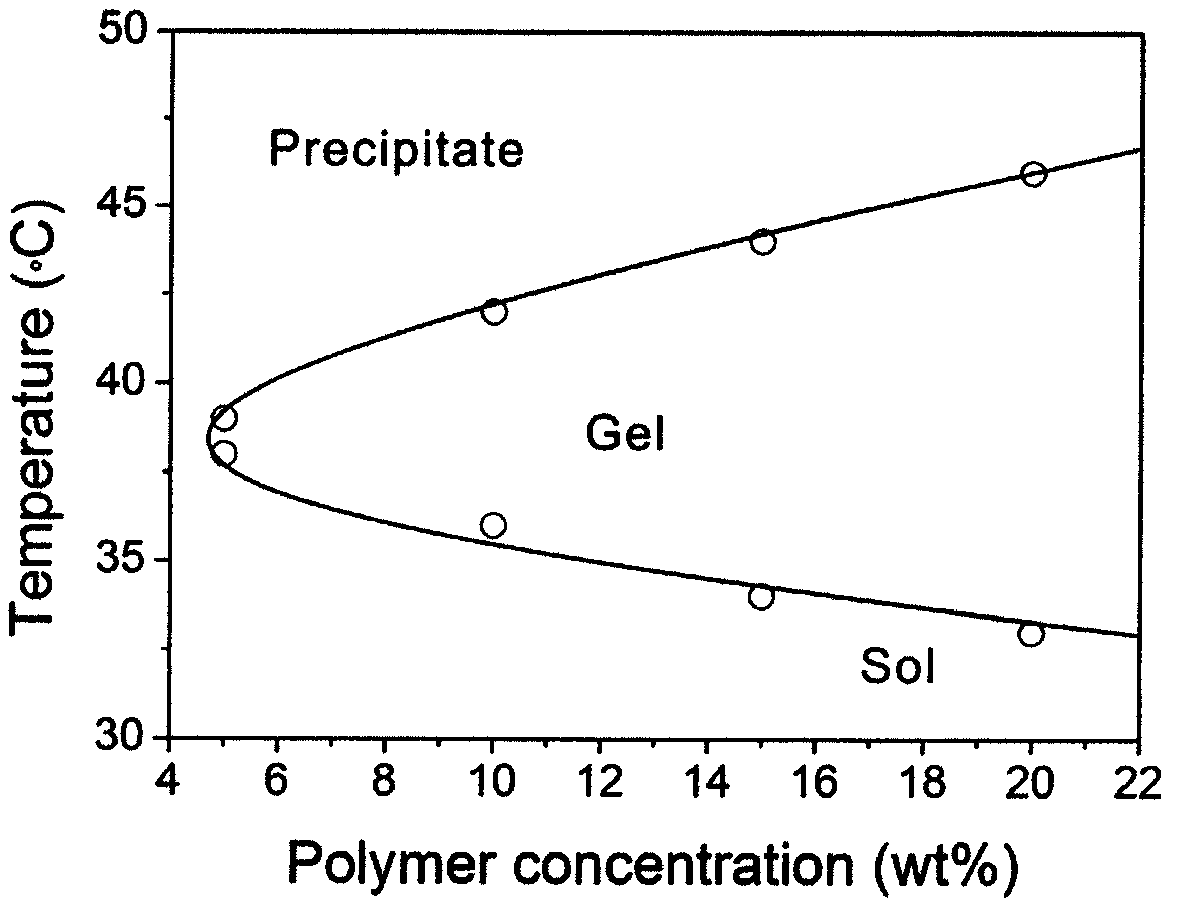

[0037] Using the preparation method in Example 1, controlling the feeding amount of the monomers glycolide (GA) and lactide (LA), to obtain polyester-polyether block copolymers with different molecular weight compositions and gelation temperatures.

[0038] Table 1 Molecular weight and gelation temperature of different polymers

[0039]

[0040] a) Gelling temperature: measured by inverted tube method, polymer concentration 20wt%

Embodiment 3

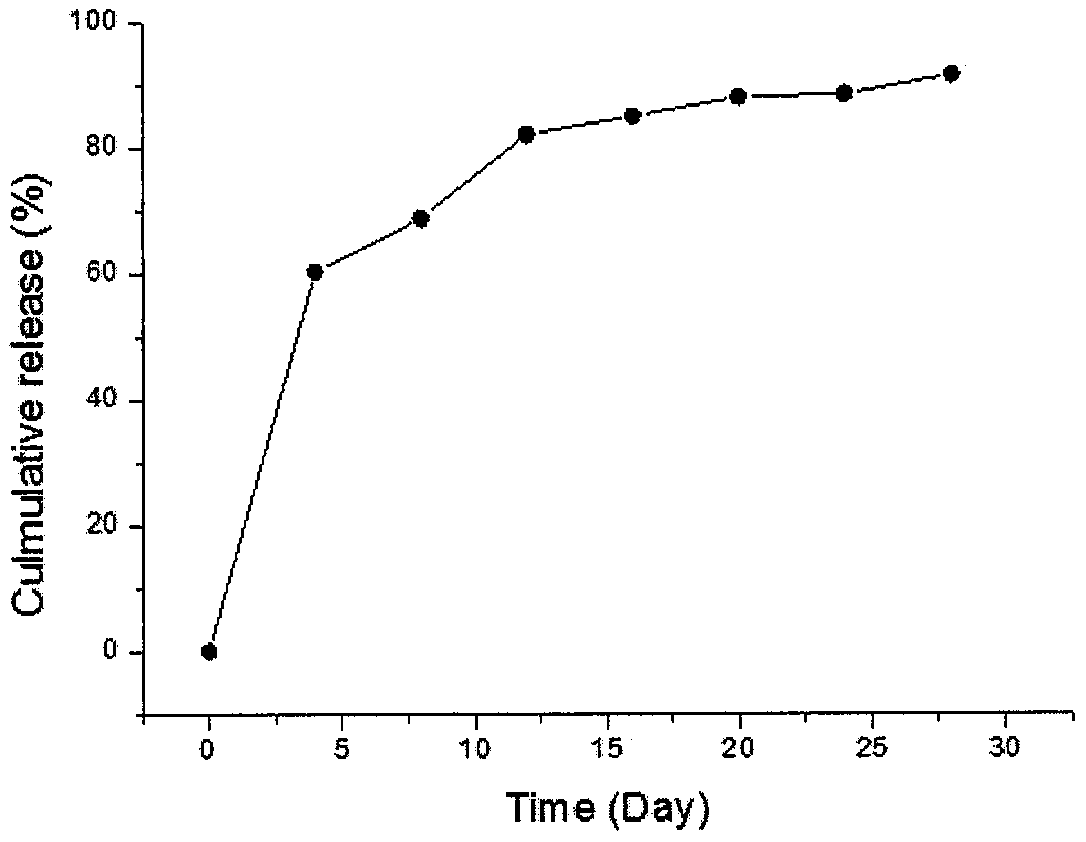

[0042] Utilizing the preparation method in Example 1, controlling the feed ratio of the monomers glycolide (GA) and lactide (LA), to obtain polyester-polyether block copolymers with different LA / GA ratios and degradation times.

[0043] Table 2 Different polymer monomer ratios and degradation time

[0044]

[0045] a) Degradation time: pH7.4 phosphate buffer solution is the degradation simulation solution, and the polymer concentration is 20wt%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com