A kind of preparation method of deuterated chloroform

A technology of deuterated chloroform and equation, applied in the field of preparation of deuterated chloroform, can solve the problems of inconvenient transportation and high price, and achieve the effects of easy separation and purification, low cost and few impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

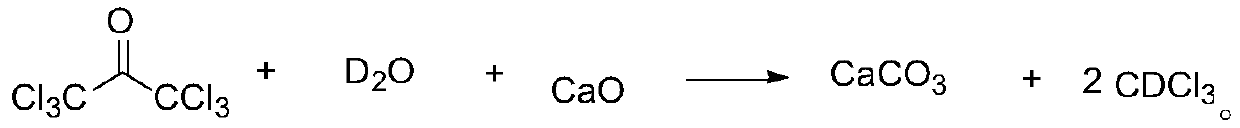

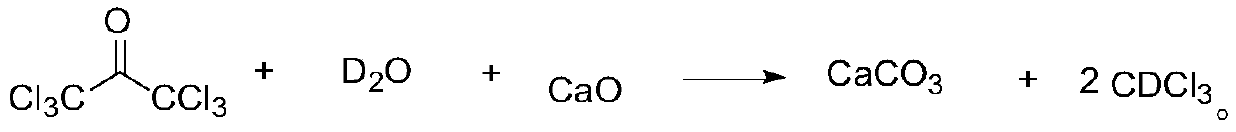

Image

Examples

Embodiment 1

[0016] Preparation of deuterated chloroform

[0017] Add 200 grams of hexachloroacetone and 30 grams of calcium oxide into a 500 ml three-necked flask with a reflux condenser, add 10 grams of heavy water dropwise while stirring, and complete the dropwise addition in about 10 minutes. Raise the temperature to 110°C for about 8 hours, and the reaction is over. , The reaction was changed to a distillation device, and the fraction at 60-61° C. was collected to obtain 115 grams of colorless transparent liquid with a yield of 95.8%.

[0018] Deuteration rate of deuterated chloroform

[0019] Accurately weigh 182mg of dimethyl terephthalate DMT and add it to a 100ml volumetric flask, dissolve it in 100ml of anhydrous methanol, after it is completely dissolved, take 1ml of the solution in the LC-MS sample bottle, and volatilize completely in an oven at 40°C. Then add 600ul deuterated chloroform to dissolve completely 1 H-NMR. The measured deuterium substitution rate is 99.85%.

Embodiment 2

[0021] Preparation of deuterated chloroform

[0022] Add 220 grams of hexachloroacetone and 28 grams of calcium oxide into a 500 ml three-neck flask with a reflux condenser, add 10 grams of heavy water dropwise while stirring, and the addition is completed in about 10 minutes, and the temperature is raised to 100 degrees for about 8 hours, and the reaction is over. , The reaction was changed to a distillation device, and the 60-61 ° C fraction was collected to obtain 110 grams of deuterated chloroform, with a yield of 91.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com