Composition for preparing weather-resistant bright white paint and preparation method of composition

A technology of composition and white topcoat, applied in the direction of coating, etc., can solve problems such as poor weather resistance, achieve good adhesion, accelerate solvent release, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

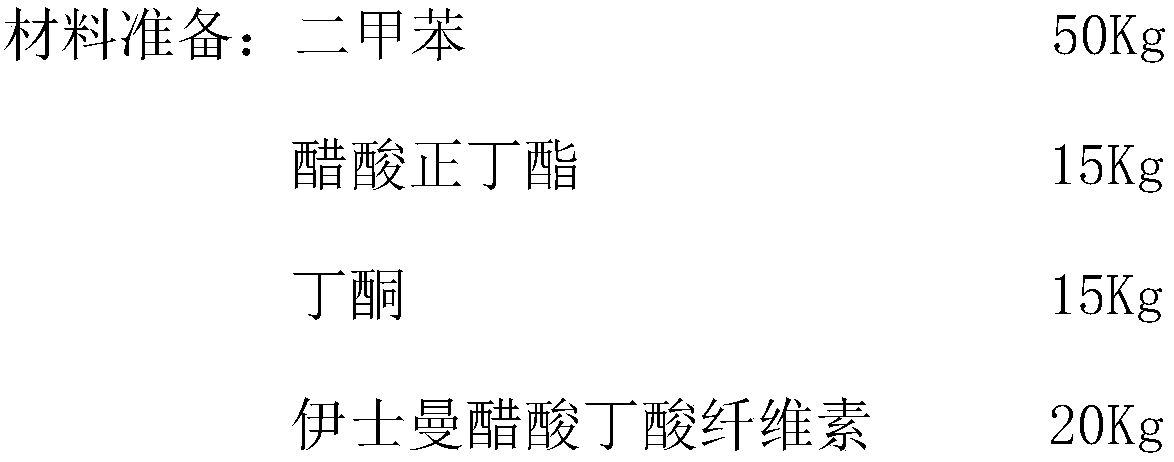

[0022] 1) Preparation of 20% concentration of cellulose acetate solution:

[0023]

[0024] Preparation process: Select a clean and satisfactory dispersion tank, put in 50Kg of xylene, 15Kg of n-butyl acetate, 15Kg of methyl ethyl ketone, put 20Kg of Eastman cellulose acetate butyrate at a low speed of 400-600 rpm, and stir Evenly, the fineness is less than or equal to 10um when the machine is shut down for inspection, and it is filtered with a 200-mesh filter and then packed into barrels for use.

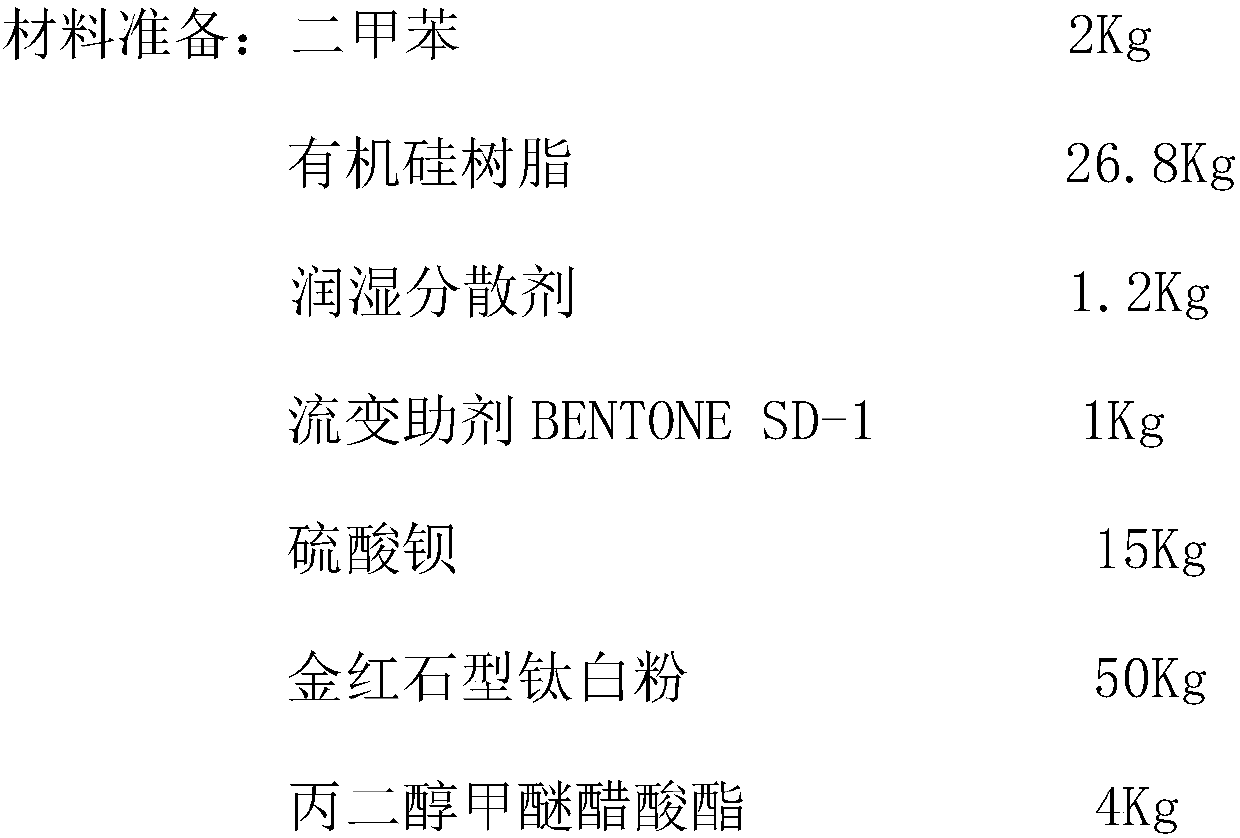

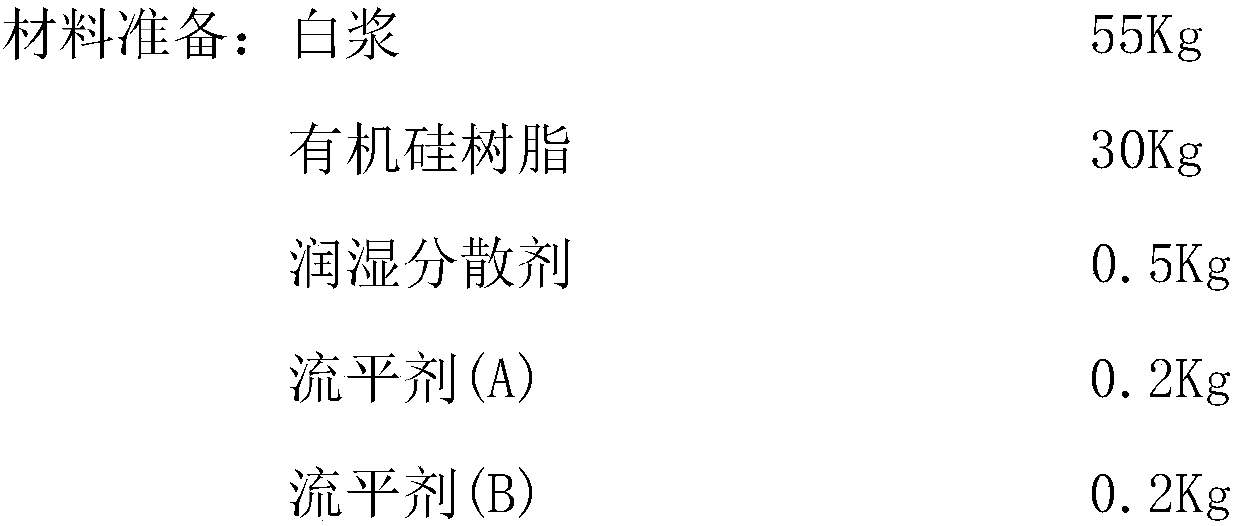

[0025] 2) Preparation of white pulp:

[0026]

[0027] Preparation process: Select a clean and satisfactory dispersion tank, add 2Kg of xylene, 26.8Kg of silicone resin, and 1.2Kg of wetting and dispersing agent in turn, stir at a low speed of 600 to 800 rpm for 10 minutes to fully uniform, and at a low speed At 600~800 rpm, add 1Kg rheological additive BENTONESD-1, 15Kg barium sulfate, 50Kg rutile titanium dioxide, add 4Kg PMA (propylene glycol methyl ether acetate) to wash...

Embodiment 2

[0044] 1) Preparation of 20% concentration of cellulose acetate solution:

[0045]

[0046] Preparation process: Select a clean and satisfactory dispersion tank, put in 50Kg of xylene, 15Kg of n-butyl acetate, 15Kg of methyl ethyl ketone, put 20Kg of Eastman cellulose acetate butyrate at a low speed of 400-600 rpm, and stir Evenly, the fineness is less than or equal to 10um when the machine is shut down for inspection, and it is filtered with a 200-mesh filter and then packed into barrels for use.

[0047] 2) Preparation of white pulp:

[0048]

[0049]Preparation process: Select a clean and satisfactory dispersion tank, add 2Kg of xylene, 26.8Kg of silicone resin, and 1.2Kg of wetting and dispersing agent in turn, stir at a low speed of 600 to 800 rpm for 10 minutes to fully uniform, and at a low speed At 600~800 rpm, add 1Kg rheological additive BENTONESD-1, 15Kg barium sulfate, 50Kg rutile titanium dioxide, add 4Kg PMA (propylene glycol methyl ether acetate) to wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com