Bimetallic organic framework antibacterial nanoparticles with photothermal effect, and preparation method and application thereof

An organic framework and nanoparticle technology, applied in the field of nanomaterials, can solve the problems of unstable thermal stability and chemical stability of antibacterial nanoparticles, no ion slow-release antibacterial effect, no photothermal effect, etc., so as to promote wound repair and healing. , promote destruction, enhance the effect of photothermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

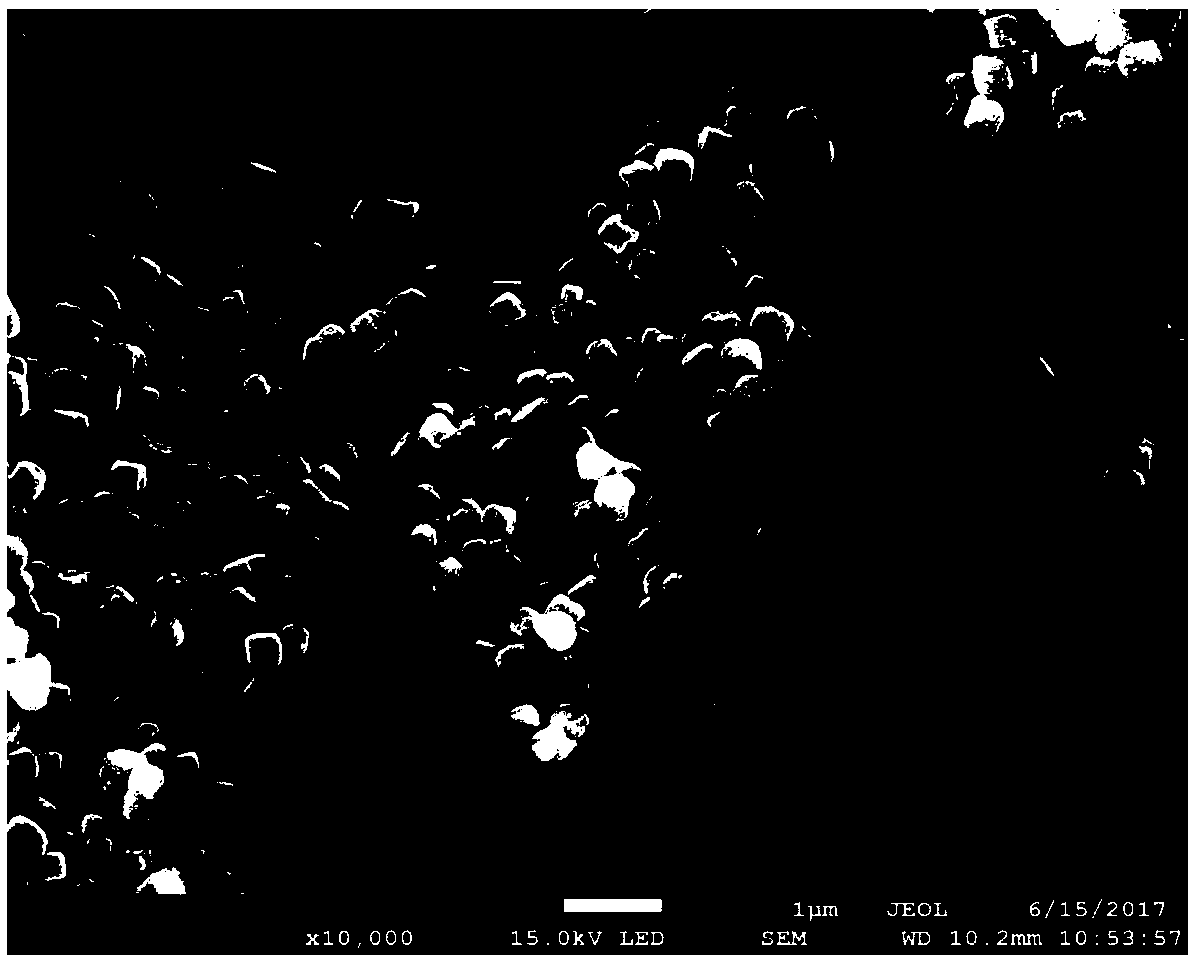

Embodiment 1

[0032] S1. Dissolve 263.4 mg (0.8 mmol) of potassium ferricyanide in 40 mL of deionized water and magnetically stir for 10 min to form a solution, and dissolve 109.04 mg (0.8 mmol) of anhydrous zinc chloride in 40 mL of deionized water and magnetically stir for 5 min to form Solution B, and solution A was added dropwise to solution B, mixed and stirred for 20 minutes, and set aside;

[0033] S2. Add 6 g of polyvinylpyrrolidone to the solution obtained in step S1 and stir for 30 minutes to make it evenly mixed, then add 0.01 M, 80 mL of hydrochloric acid, stir for 15 minutes to fully dissolve it, and leave it standing at 80° C. for aging and precipitation for 32 hours;

[0034] S3. Centrifuge the product obtained in step S2 at 12,000 rpm for 10 min, separate the product solution to obtain a blue precipitate, and centrifuge and wash with ethanol and deionized water for 3 times, respectively, to obtain the precipitate product;

[0035] S4. Place the product obtained in step S3 in...

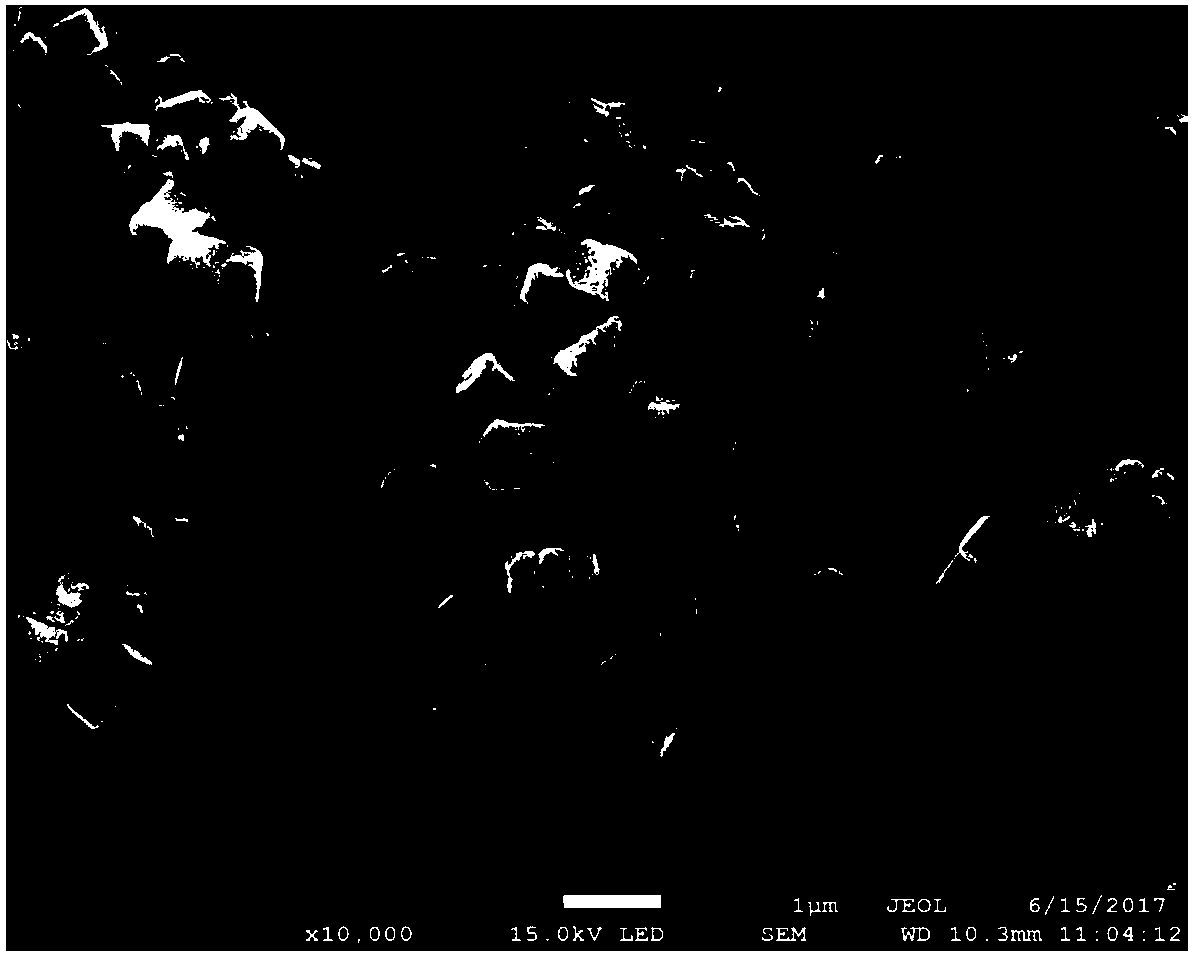

Embodiment 2

[0037] S1. Dissolve 263.4 mg (0.8 mmol) of potassium ferricyanide in 40 mL of deionized water and magnetically stir for 13 minutes to form A solution, and dissolve 81.78 mg (0.6 mmol) of anhydrous zinc chloride in 40 mL of deionized water and magnetically stir for 8 minutes to form Solution B, and solution A was added dropwise to solution B, mixed and stirred for 25 minutes, and set aside;

[0038] S2. Add 6 g of polyvinylpyrrolidone to the solution obtained in step S1 and stir for 40 minutes. After mixing evenly, add 0.01 M, 80 mL of hydrochloric acid, stir for 10 minutes to fully dissolve, and leave it at 82° C. for aging and precipitation for 30 hours;

[0039] S3. Centrifuge the product obtained in step S2 at 10,000 rpm for 15 minutes, separate the product solution to obtain a blue precipitate, and centrifuge and wash with ethanol and deionized water for 3 times, respectively, to obtain the precipitated product;

[0040] S4. Place the product obtained in step S3 in a freez...

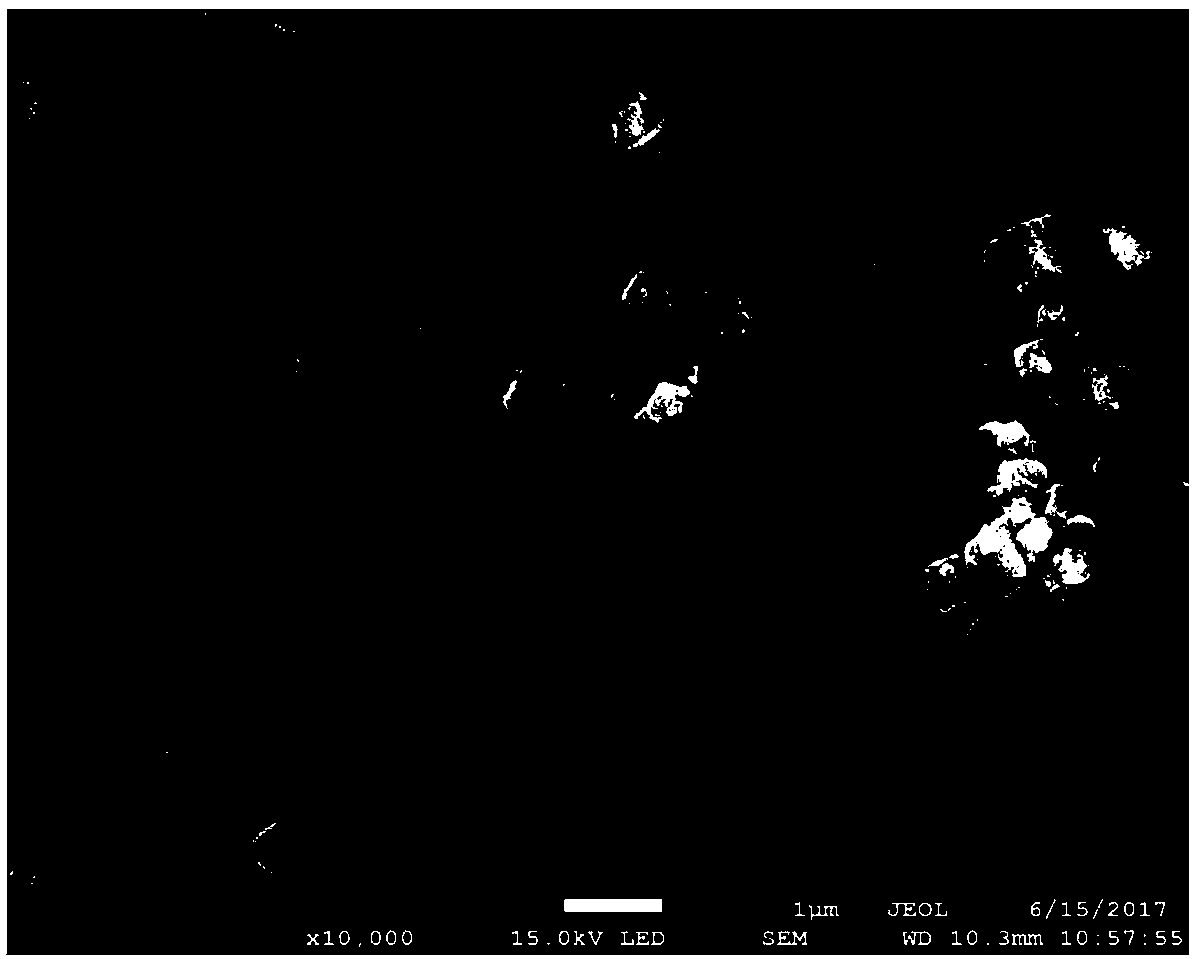

Embodiment 3

[0042] S1. Dissolve 263.4mg (0.8mmol) of potassium ferricyanide in 40mL of deionized water and magnetically stir for 11min to form A solution, and dissolve 54.526mg (0.4mmol) of anhydrous zinc chloride in 40mL of deionized water and magnetically stir for 3min to form Solution B, and solution A was added dropwise to solution B, mixed and stirred for 35 minutes, and set aside;

[0043] S2. Add 6 g of polyvinylpyrrolidone to the solution obtained in step S1 and stir for 50 minutes. After mixing evenly, add 0.01 M, 80 mL of hydrochloric acid, stir for 14 minutes to fully dissolve, and leave it at 84° C. for aging and precipitation for 28 hours;

[0044] S3. Centrifuge the product obtained in step S2 at 12,000 rpm for 10 min, separate the product solution to obtain a blue precipitate, and centrifuge and wash with ethanol and deionized water for 3 times, respectively, to obtain the precipitate product;

[0045] S4. Place the product obtained in step S3 in a freezer for 7 hours to fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com