Zirconia machining equipment

A processing equipment, zirconia technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of high cost, low processing precision, high zirconia processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention provides a zirconia processing equipment. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

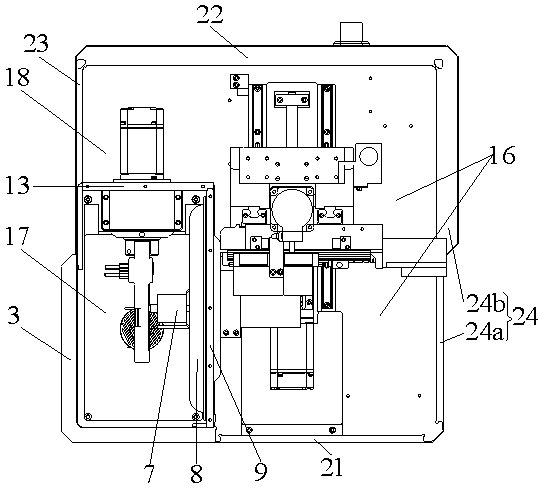

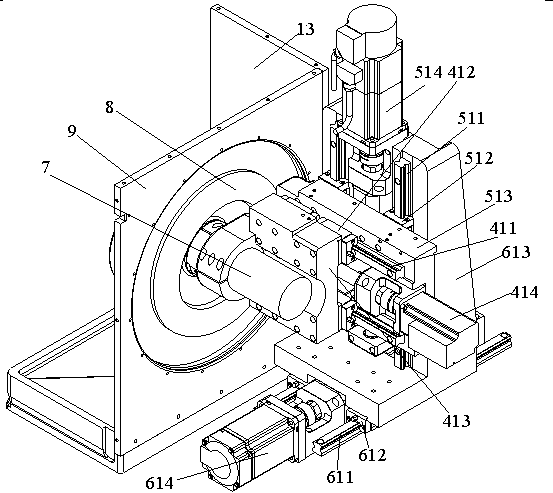

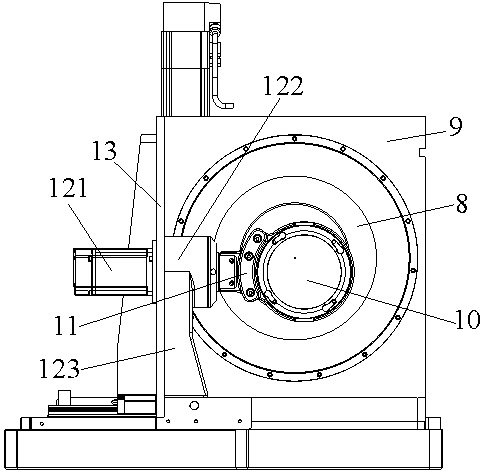

[0034] Such as Figure 1 to Figure 3 As shown, the zirconia processing equipment provided by the present invention includes a base 1, a shell assembly, a door body 3, an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis moving mechanism, a main shaft 7, a protective ring 8, and a fixed protective ring Shell 9, workbench 10, tool magazine 11, A-axis rotation mechanism 12, first support plate 13, negative pressure source 14, air outlet duct 15 and control system.

[0035] In a preferred embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com