Electroplating wastewater recycling process and electroplating wastewater recycling apparatus

A technology of electroplating wastewater and recycling equipment, which is applied in the direction of water/sewage treatment, metallurgical wastewater treatment, neutralization water/sewage treatment, etc. It can solve the problems of electroplating wastewater that cannot be recycled and resource waste, and achieve the reduction of pollutant discharge. Low investment, reliable system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of electroplating wastewater recycling process of the present invention comprises the following steps:

[0031] 1) Preliminarily filter the electroplating wastewater stock solution to be treated to adjust the pH value, collect after removing the particulate suspended impurities in the electroplating wastewater stock solution, and obtain the treatment solution A; wherein the preliminary filtration includes sand filter and carbon filter, sand filter (30CMH): Used to intercept suspended solids, colloids and other particulate impurities in water, thereby removing impurities in water (when the pH value of the drainage is alkaline and without acid adjustment, the interception effect is better), and the equipment is judged according to the water inlet and outlet pressure during operation , when the pressure difference is greater than 1.5KG, manual backwashing is used; carbon filter (30CMH): activated carbon absorbs and removes organic matter, colloids, micro...

Embodiment 2

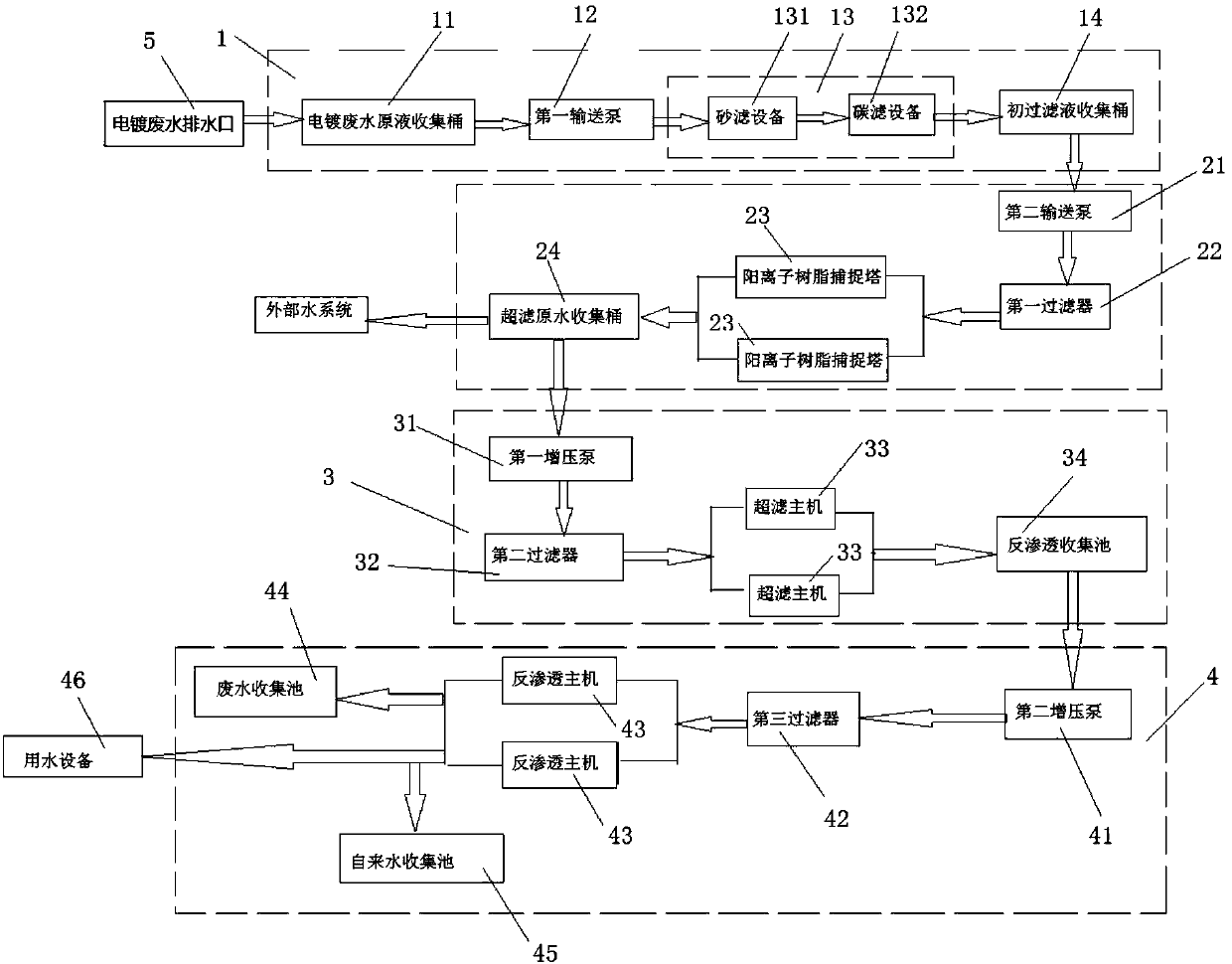

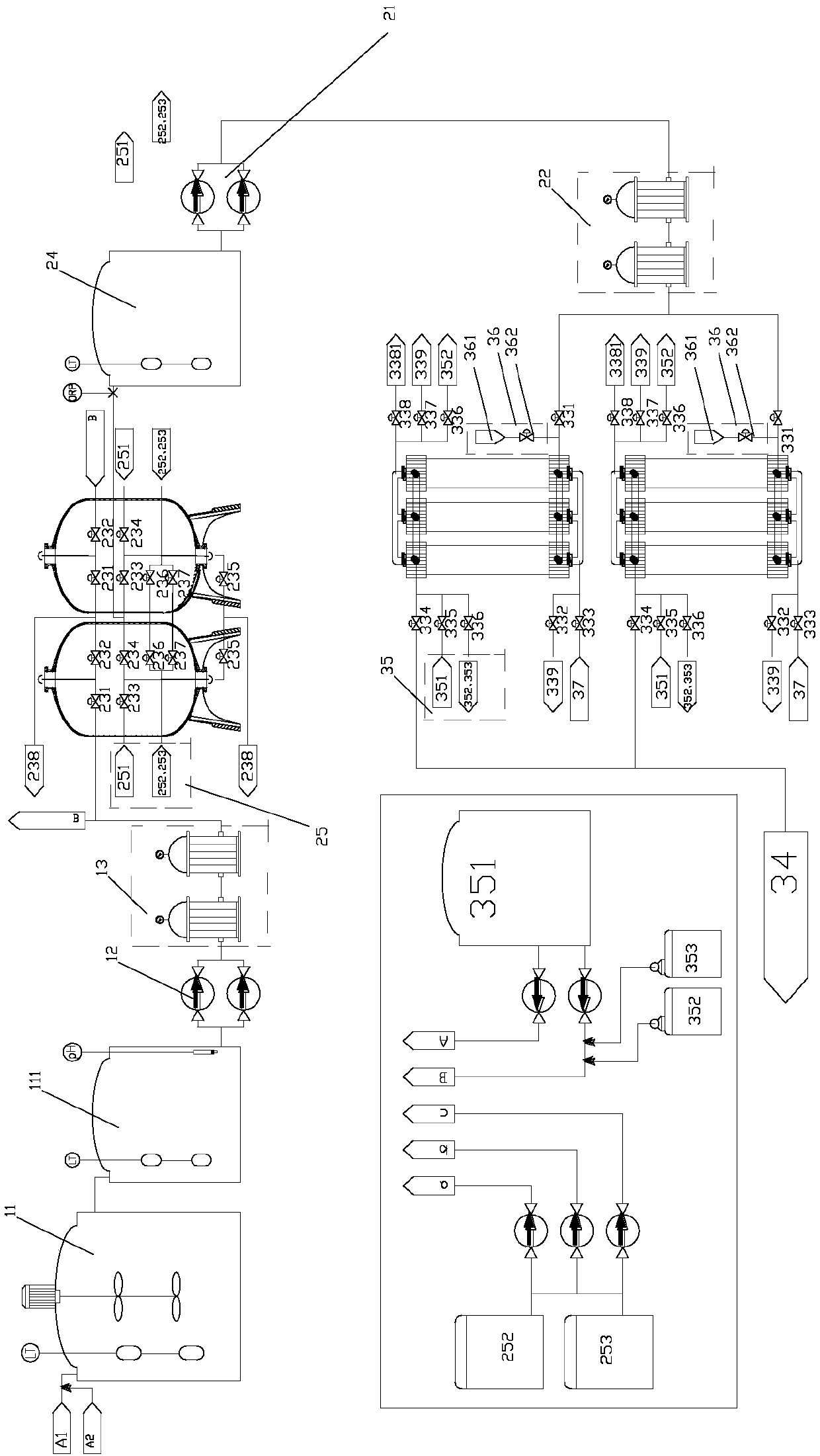

[0037] Example 2 A kind of electroplating wastewater recovery process equipment constructed according to a kind of electroplating wastewater recovery process in Example 1, including a pretreatment unit 1 for removing suspended particles in electroplating wastewater, for removing metal ions in electroplating wastewater The cationic resin exchange unit 2, the ultrafiltration unit 3 for intercepting macromolecules in the electroplating wastewater, the reverse osmosis unit 4 and the controller for reducing the conductivity of the treated water, the water inlet of the pre-treatment unit is connected with the outside to be treated The electroplating wastewater outlet is connected, the water outlet of the pretreatment unit is connected with the water inlet of the cationic resin exchange unit, and the water outlet of the cationic resin exchange unit is divided into two paths, the first path is discharged according to the electroplating water standard, and the second path is connected to...

Embodiment 3

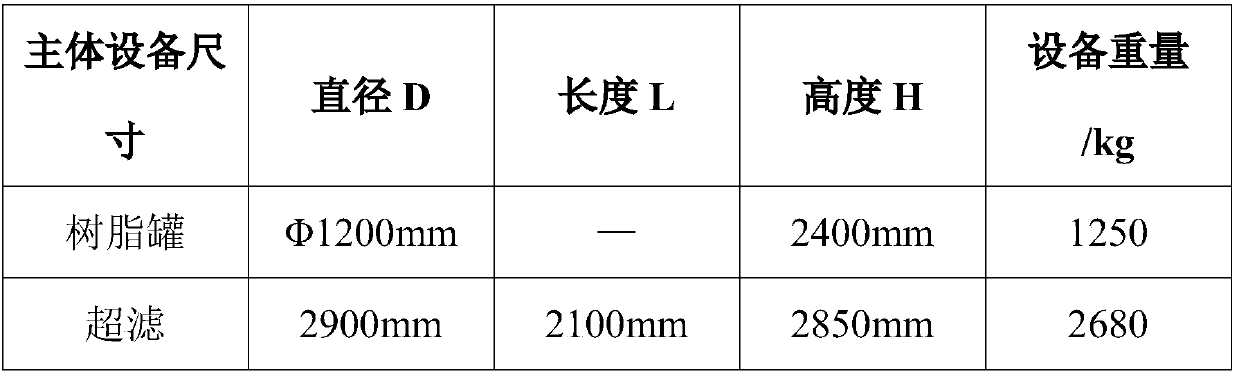

[0050] Embodiment 3 This embodiment is an appropriate improvement to Embodiment 2: the pretreatment unit 1 electroplating wastewater stock solution collection bucket 11 (with a capacity of 5 m 3 ) downstream of the overflow water tank 111 (capacity is 3m 3 ), the filter equipment 13 is changed into two consecutive bag filters (accuracy is 50 μm, and the treatment flow rate is 30m 3 / h), and a stirrer and a liquid level switch (LT) are established in the electroplating wastewater stoste collection bucket 11, and a liquid level switch (LT) and a pH meter are provided in the overflow water tank; the first delivery pump is a group, and The conveying capacity is 30m 3 / h frequency conversion delivery pump; and the electroplating wastewater stock solution needs to add acid to adjust the pH value to 9.5-11 before entering the electroplating wastewater stock solution collection barrel 11;

[0051] The cation resin capture tower 23 of the cation resin exchange unit is two sets of hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com