Continuous rotary biomass pyrolysis carbonization equipment

A biomass pyrolysis and rotary technology, which is used in rotary carbonization furnaces, biofuels, special forms of dry distillation, etc., can solve the problems of polluting energy, waste, and inability to recycle combustible gases, so as to reduce environmental pollution and save energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

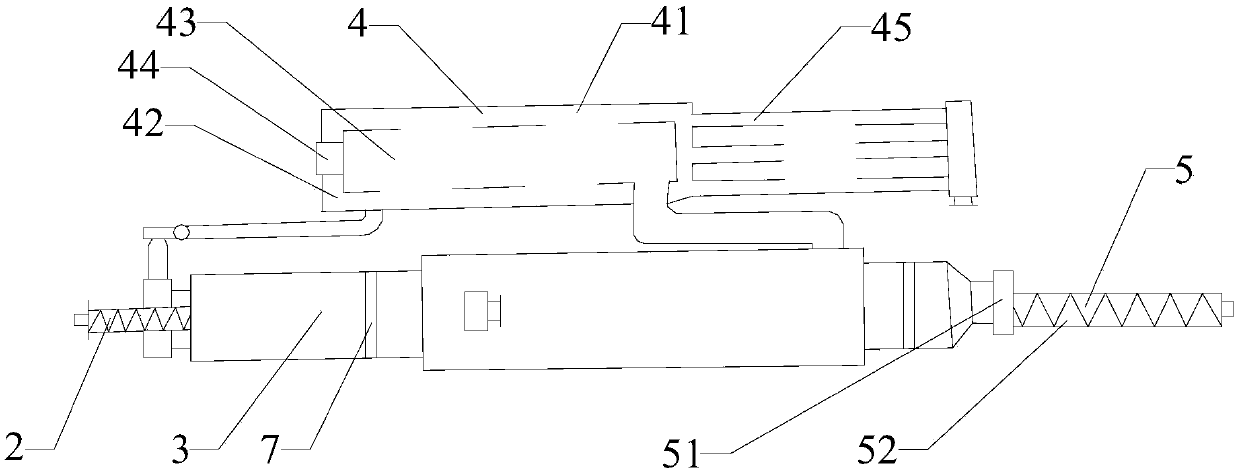

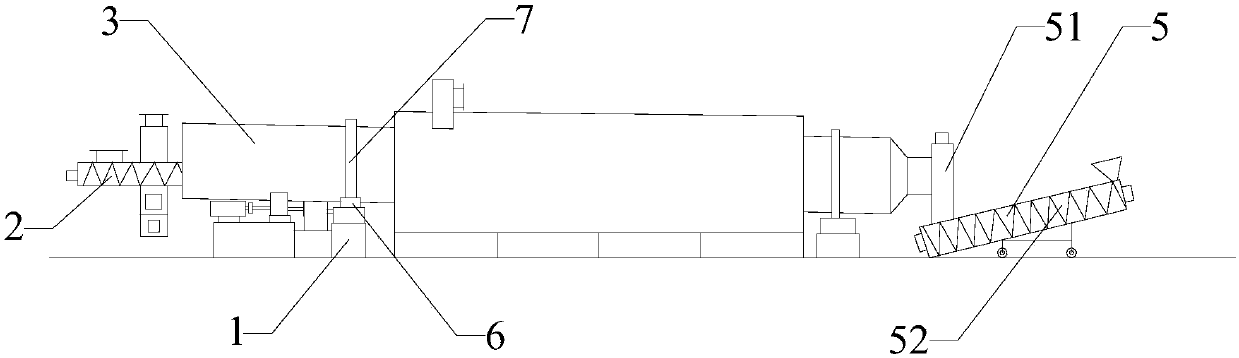

[0038]A continuous rotary biomass pyrolysis carbonization equipment, including a base 1, a screw feeder 2, a carbonization converter 3, a heating device 4 and a carbon cooling device 5; the base 1 is provided with a screw feeder 2, carbonization Converter 3, heating equipment 4 and carbon cooling equipment 5; the end of the screw feeder 2 is connected to the beginning of the carbonization converter 3, the outer surface of the middle section of the carbonization converter 3 is provided with a heat preservation furnace body, and the middle section of the carbonization converter 3 Vent holes are provided, and the middle section of the carbonization converter 3 communicates with the heat preservation furnace through the vent holes; the heating equipment 4 includes a high-temperature furnace 41, and the high-temperature furnace 41 is provided with an energy storage chamber 42 and a combustion chamber 43. The energy storage chamber 42 is arranged outside the combustion chamber 43. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com