Method for separating and recovering valuable metal from high-bismuth copper slag

A technology for separation and recovery of valuable metals, applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of increased labor intensity, low direct recovery rate, and deterioration of copper removal efficiency, and achieve convenient operation and comprehensive recovery High degree of environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

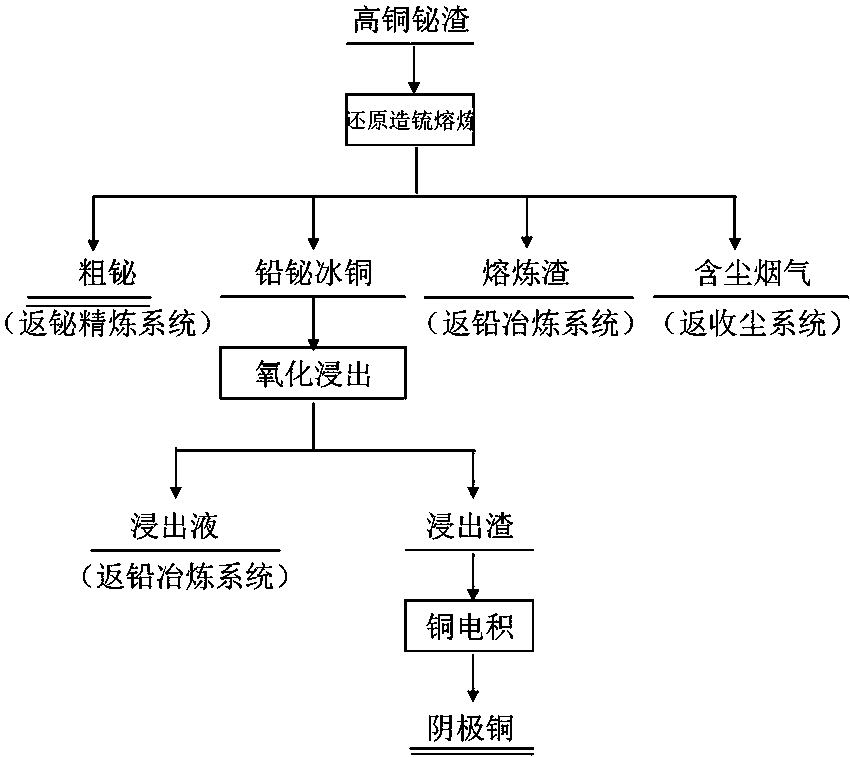

Image

Examples

Embodiment 1

[0018] (1) Put the high-copper-bismuth slag into the enrichment furnace for sulfur production and reduction. The temperature is controlled at 1150°C and kept for 3 hours. Obtain crude bismuth, lead-bismuth matte, smelting slag and dust-containing flue gas. Crude bismuth is sent to the refining system for further processing to recover bismuth, and the smelting slag is returned to the lead smelting system to comprehensively recover valuable metals such as Au and Ag, and the dust-containing flue gas is sent to dust collection system processing;

[0019] (2) Crush the lead-bismuth matte in step (1) to more than 300 mesh, add acid to adjust the slurry, and then add it to a high-pressure reactor for oxidation leaching. The oxygen pressure leaching conditions are: sulfuric acid concentration 180g / L, liquid-solid ratio 10:1, temperature 180°C, oxygen pressure in the kettle 3.0MPa, stirring speed 600 r / min, reaction time 4 h;

[0020] The main composition and weight percentage of the ...

Embodiment 2

[0024] (1) Put the high-copper-bismuth slag into the enrichment furnace for sulfur production and reduction. The temperature is controlled at 1200°C and kept for 3 hours. Obtain crude bismuth, lead-bismuth matte, smelting slag and dust-containing flue gas. Crude bismuth is sent to the refining system for further processing to recover bismuth, and the smelting slag is returned to the lead smelting system to comprehensively recover valuable metals such as Au and Ag, and the dust-containing flue gas is sent to dust collection system processing;

[0025] (2) Crush the lead-bismuth matte in step (1) to more than 300 mesh, add acid to adjust the slurry, and then add it to a high-pressure reactor for oxidation leaching. The oxygen pressure leaching conditions are: sulfuric acid concentration 160g / L, liquid-solid ratio 8:1, temperature 150°C, oxygen pressure in the kettle 3.0MPa, stirring speed 600 r / min, reaction time 4 h;

[0026] The main composition and weight percentage of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com