Composite partition board

A composite partition wall and substrate layer technology, which is applied in the field of building panels, can solve the problems of low strength, easy cracking of joints, and single function of partition boards, so as to improve bonding strength, prevent joint cracking, and achieve strong bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

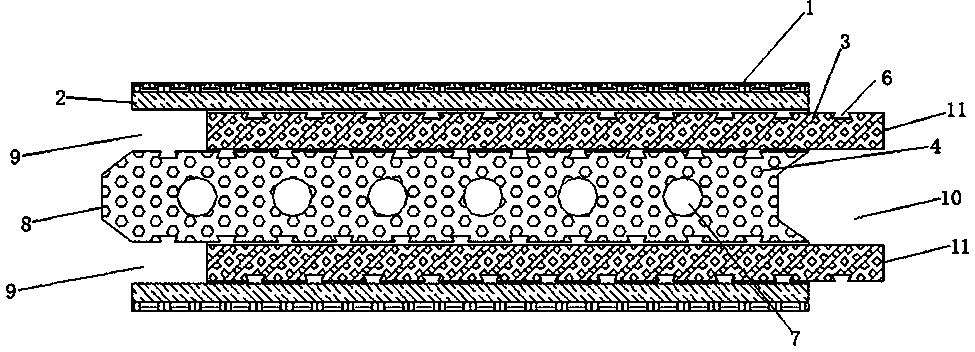

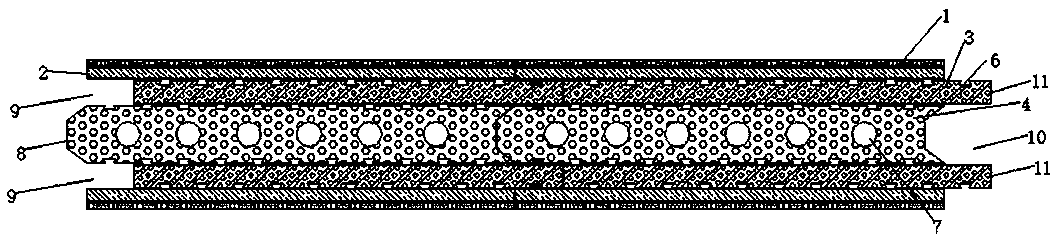

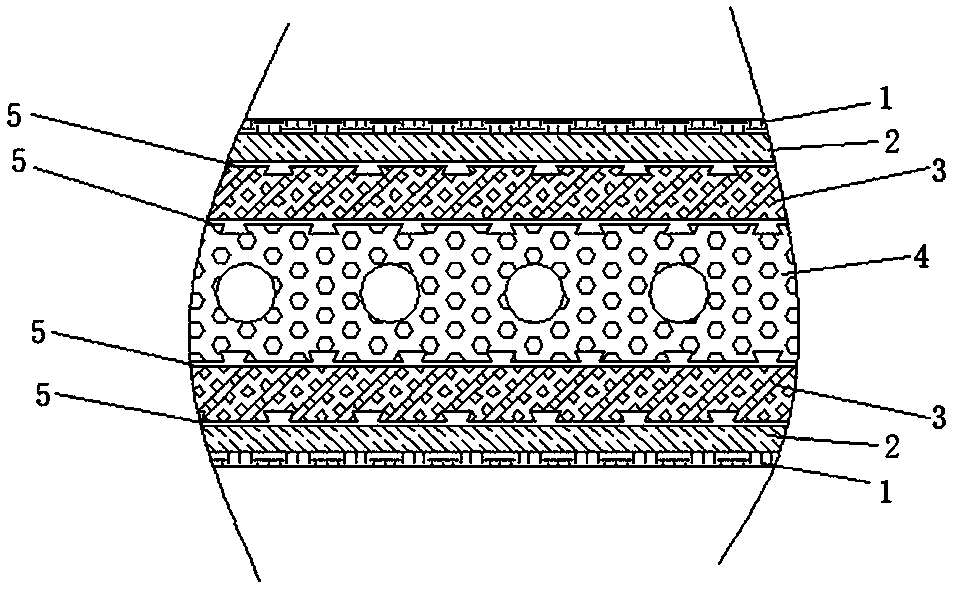

[0025] Example: such as Figure 1 to Figure 7 As shown, a composite partition wall panel of the present invention includes a finishing layer 1, a substrate layer 2, a sound insulation layer 3, an insulating layer 4 and an adhesive layer 5; the finishing layer 1 is arranged on the outer surface of the substrate layer 2, The veneer layer 1 is a natural wood veneer decorative panel or a technical wood veneer decorative panel. The veneer layer 1 is fixed on the outer surface of the substrate layer 2 in the factory through the factory prefabrication process, eliminating the need to apply putty on the construction site Wet work for leveling and pasting the finish layer 1; the substrate layer 2 is a calcium silicate board or asbestos-free fiber cement board for heat preservation; the sound insulation layer 3 is a damping sound insulation board for sound insulation, and has environmental protection, fire prevention, heat preservation Mildew, moisture-proof and high strength, high impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com