Junction temperature test method of AlGaN/GaN high electron mobility transistor

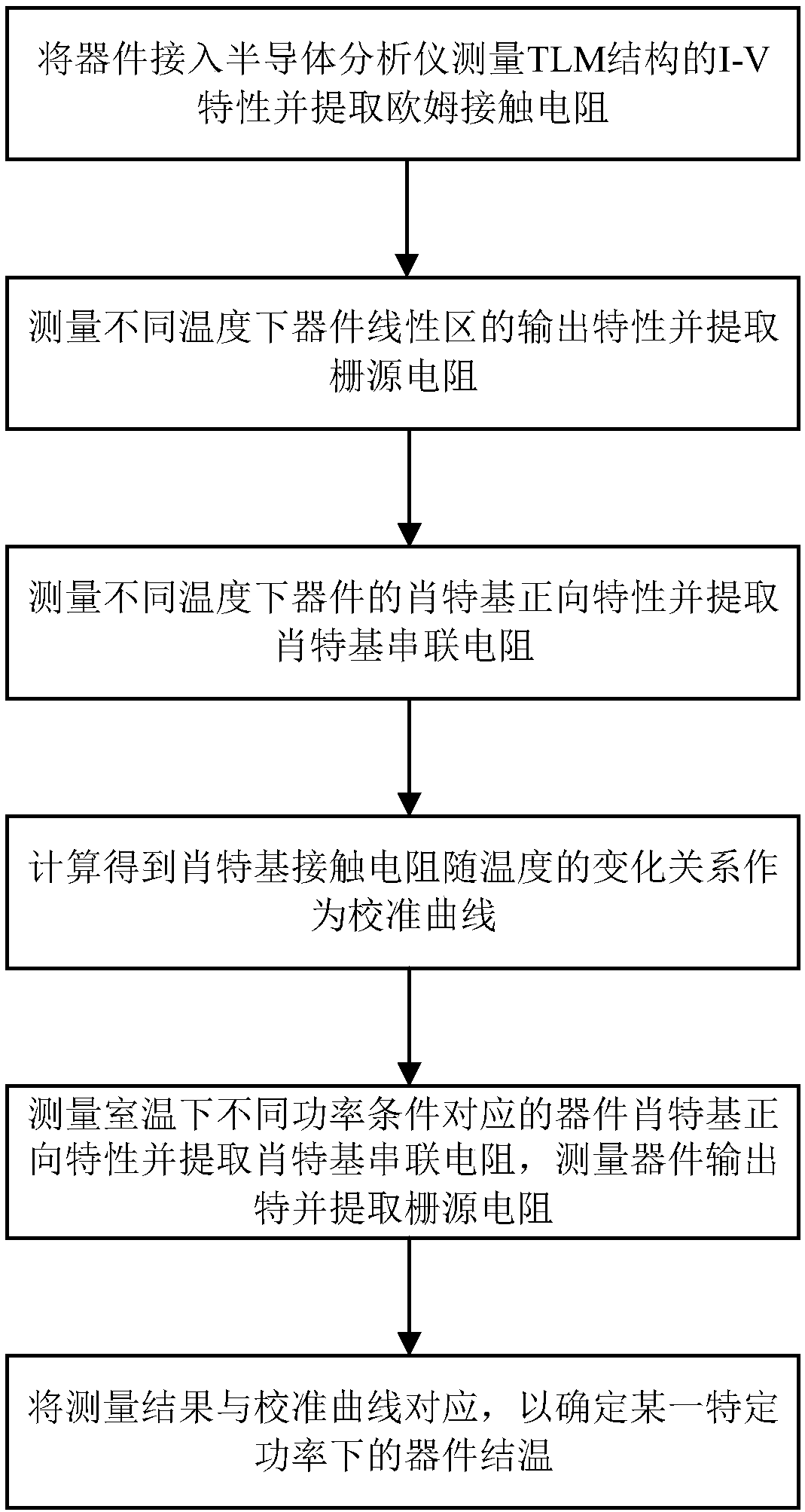

A technology with high electron mobility and transistors, which is applied in semiconductor/solid-state device testing/measurement, circuits, electrical components, etc. It can solve problems such as large error in measurement results, failure to meet measurement requirements, and underestimation of device junction temperature. Simplicity, increased accuracy, and easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Testing the junction temperature of an AlGaN / GaN HEMT device on a sapphire substrate.

[0019] Step 1, measure the ohmic contact resistance R of the transmission line model TLM structure C .

[0020] 1a) Place the tested AlGaN / GaN high electron mobility transistor HEMT device on the sapphire substrate on the probe station, apply a voltage to the transmission line model TLM structure through the semiconductor parameter analyzer, and set the voltage range from -0.5V to 0.5V ;

[0021] 1b) Test the current-voltage I-V characteristics of the TLM structure of the transmission line model, and extract the ohmic contact resistance R of the device under test C ;

[0022] Step 2, measure the on-resistance R of the AlGaN / GaN high electron mobility transistor HEMT device ON0 .

[0023] 2a) Place the tested AlGaN / GaN high electron mobility transistor HEMT device on the probe station, the source is grounded, and the gate voltage is set to V GS and drain voltage V ...

Embodiment 2

[0043] Embodiment 2: Testing the junction temperature of an AlGaN / GaN HEMT device on a silicon carbide substrate.

[0044] Step 1, measure the ohmic contact resistance R of the transmission line model TLM structure C .

[0045] Step 1 of this example is the same as Step 1 of Embodiment 1.

[0046] Step 2, measure the on-resistance R of the AlGaN / GaN high electron mobility transistor HEMT device ON0 .

[0047] 2a) Place the tested AlGaN / GaN high electron mobility transistor HEMT device on the probe station, the source is grounded, and the gate voltage is set to V GS and drain voltage V DS The pulse width is 500ns, the pulse period is 1ms, and the gate static bias point is V GSQ with the source statically biased at the point V DSQ is 0V, the drain voltage V DS From 0V to 12V, the gate voltage V is applied to it through the semiconductor parameter analyzer GS and drain voltage V DS ;

[0048] 2b) Adjust the temperature controller to apply different external temperatures...

Embodiment 3

[0068] Embodiment 3: Junction temperature test of AlGaN / GaN HEMT device on silicon substrate

[0069] Step 1, measure the ohmic contact resistance R of the transmission line model TLM structure C .

[0070] This step is the same as Step 1 in Example 1.

[0071] Step 2, measure the on-resistance R of the AlGaN / GaN high electron mobility transistor HEMT device ON0 .

[0072]2a) Place the tested AlGaN / GaN high electron mobility transistor HEMT device on the probe station, the source is grounded, and the gate voltage is set to V GS and drain voltage V DS The pulse width is 500ns, the pulse period is 1ms, and the gate static bias point is V GSQ with the source statically biased at the point V DSQ is 0V, the drain voltage V DS From 0V to 12V, the gate voltage V is applied to it through the semiconductor parameter analyzer GS and drain voltage V DS ;

[0073] 2b) Adjust the temperature controller to apply different external temperatures to the device, measure the output cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com