Method of preparing battery level lithium carbonate by using salt lake lithium ores

A lithium carbonate, battery-level technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of low output, unfavorable industrial production, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

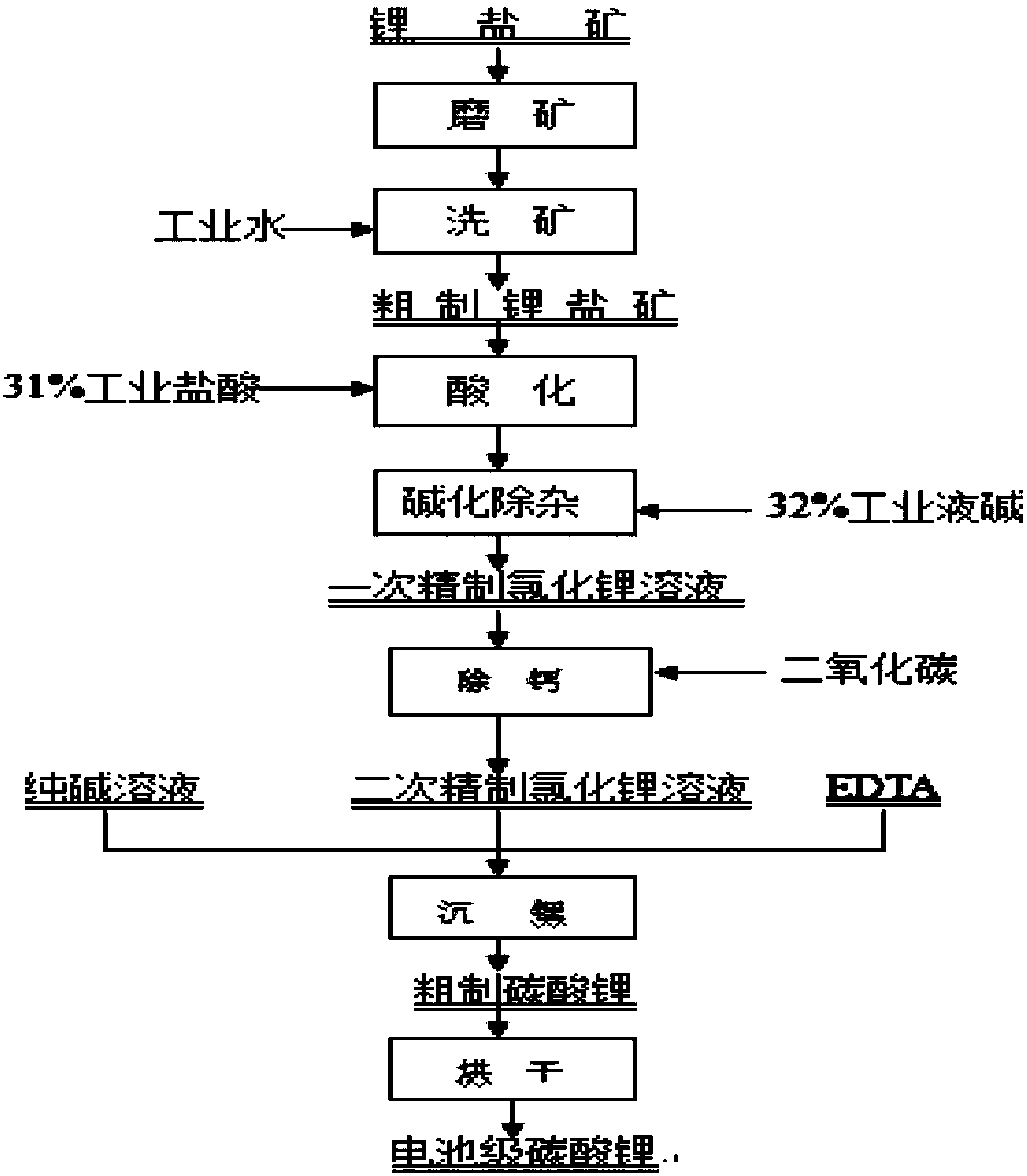

Method used

Image

Examples

Embodiment 1

[0059] A. Ball mill crushing: Put the massive lithium salt ore into a ball mill and crush it into particles of 0.02mm-0.08mm. Lithium salt ore composition is as shown in table 1:

[0060] Table 1 Lithium salt ore composition (unit: %)

[0061] Li

Na

K

Ca

Mg

Fe

B

Al

h 2 o

10.65

6.1

1.8

0.38

0.42

0.022

0.13

0.031

13.59

[0062]B. Slurry and washing of sodium, potassium and boron to prepare crude lithium salt ore: adjust 0.02mm-0.08mm granular lithium salt ore and tap water into a slurry at a liquid-solid ratio of 2:1, heat up to 95°C, stir and wash for 1 hour, Centrifuge to obtain crude lithium salt ore. Among them, the removal rate of potassium is 83.15%, and the removal rate of boron is 75.6%.

[0063] Crude lithium salt ore composition is as shown in table 2:

[0064] Table 2 Crude lithium salt ore composition (unit: %)

[0065] Li

Na

K

Ca

Mg

Fe

B

Al

h 2 o ...

Embodiment 2

[0080] A. Ball mill crushing: Put the massive lithium salt ore into a ball mill and crush it into particles of 0.02mm-0.08mm. Lithium salt ore composition is shown in Table 6:

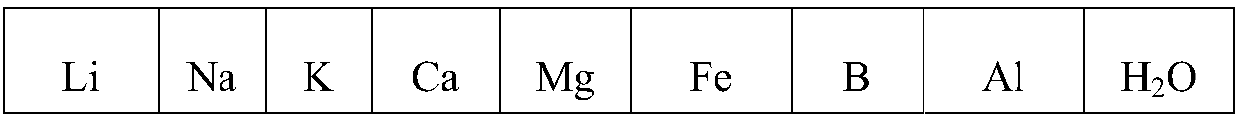

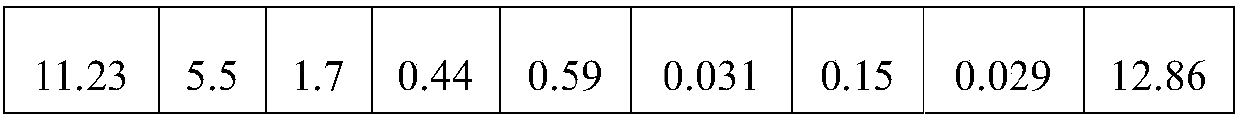

[0081] Table 6 lithium salt ore composition (unit: %)

[0082]

[0083]

[0084] B. Slurry washing of sodium, potassium, and boron: Mix 0.02mm-0.08mm granular lithium salt ore and tap water into a slurry at a liquid-solid ratio of 3:1, heat up to 90°C, stir and wash for 40 minutes, and centrifuge to obtain crude lithium salt mine. Among them, the removal rate of potassium is 86.12%, and the removal rate of boron is 72.84%.

[0085] Crude lithium salt ore composition is as shown in table 7:

[0086] Table 7 crude lithium salt ore composition (unit: %)

[0087] Li

Na

K

Ca

Mg

Fe

B

Al

h 2 o

12.89

0.98

0.12

0.43

0.56

0.03

0.016

0.03

13.63

[0088] C, the preparation of a refined lithium chloride solution: slowly add 31% hy...

Embodiment 3

[0100] A. Ball mill crushing: Put the massive lithium salt ore into a ball mill and crush it into particles of 0.02mm-0.08mm. The composition of lithium salt ore is shown in Table 11:

[0101] Table 11 lithium salt ore composition (unit: %)

[0102] Li

[0103] B. Slurry washing of sodium, potassium and boron: Mix 0.02mm-0.08mm granular lithium salt ore and tap water into a slurry at a liquid-solid ratio of 3:1, heat up to 100°C, stir and wash for 1 hour, and centrifuge to obtain crude lithium salt mine. Among them, the removal rate of potassium is 89.06%, and the removal rate of boron is 71.99%.

[0104] The composition of crude lithium salt ore is shown in Table 12:

[0105] Table 12 crude lithium salt ore composition (unit: %)

[0106] Li

[0107] C, the preparation of a refined lithium chloride solution: slowly add 31% hydrochloric acid to the crude lithium salt ore, adjust the reaction pH to 2 and maintain it for 15 minutes; then add 32% liquid cau...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap