Odor-free and solid waste-free squeezed liquid treatment process for refuse transfer station

A treatment process and transfer station technology, applied in the direction of contaminated groundwater/leachate treatment, sedimentation treatment, special treatment targets, etc., can solve the problem of unstable water output, high concentration of pollutants, large quality changes, etc. problems, to achieve the effect of small footprint, large specific surface area, and improvement of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is used for a daily average extrusion liquid production volume of 20m 3 / d's garbage transfer station.

[0030]The rubbish squeeze liquid emits a disgusting stench, a thick oil film floats on the surface, the liquid is turbid, and the transparency is extremely low. The quality of the raw water is COD Cr 10000~12000mg / L, NH 3 -N 200~600mg / L, TP 500~800mg / L, TN 400~900mg / L, pH 3.0~5.0.

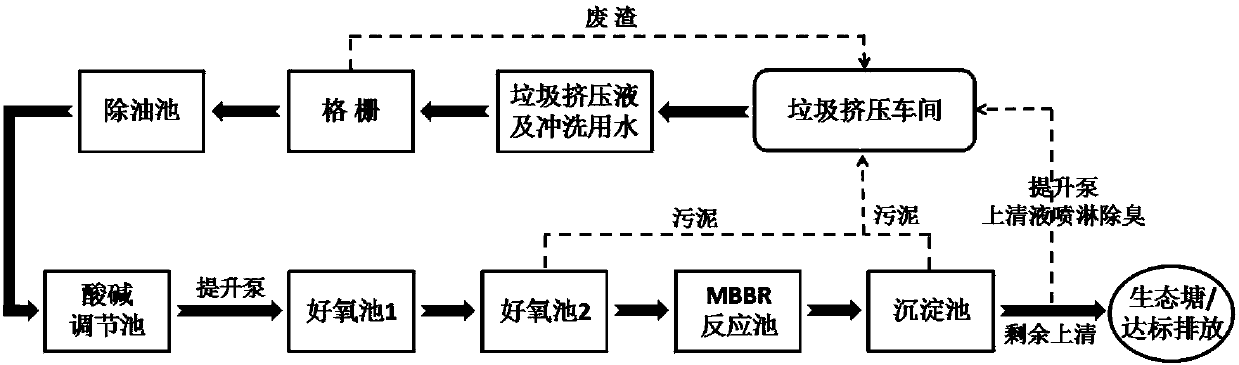

[0031] Its technological process of adopting this invention process to process rubbish extrusion liquid is as follows:

[0032] The garbage extrusion liquid flows through the ground groove first through the stainless steel grid. The effective spacing of the grid bars is 5mm, and the grid bar width is 10mm. Continue to enter the degreasing pool (effective volume 1.0m 3 ), the length of the clapboard is 0.4m, the hydraulic retention time is 1.2h, and the floating oil is removed, and then the sewage enters the acid-base adjustment tank made of PE through the pipeline (th...

Embodiment 2

[0051] In the present invention, the system effluent is used to spray and flush the garbage transfer station and the extrusion workshop, and the odor concentration is detected before and after flushing and spraying. The results are shown in Table 2:

[0052] Table 2 Comparison before and after flushing (spraying) of garbage transfer station and extrusion workshop

[0053]

Embodiment 3

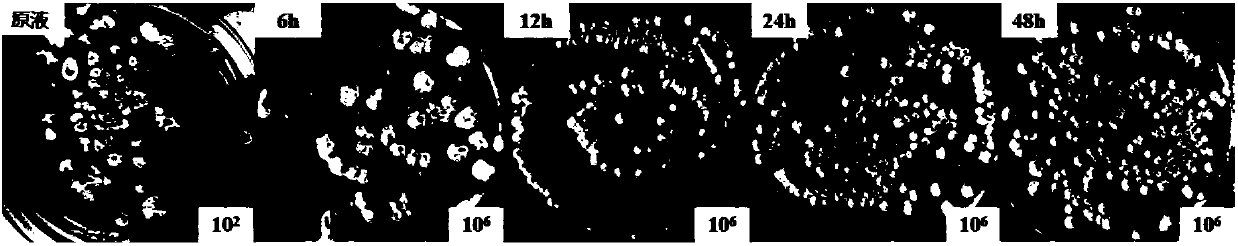

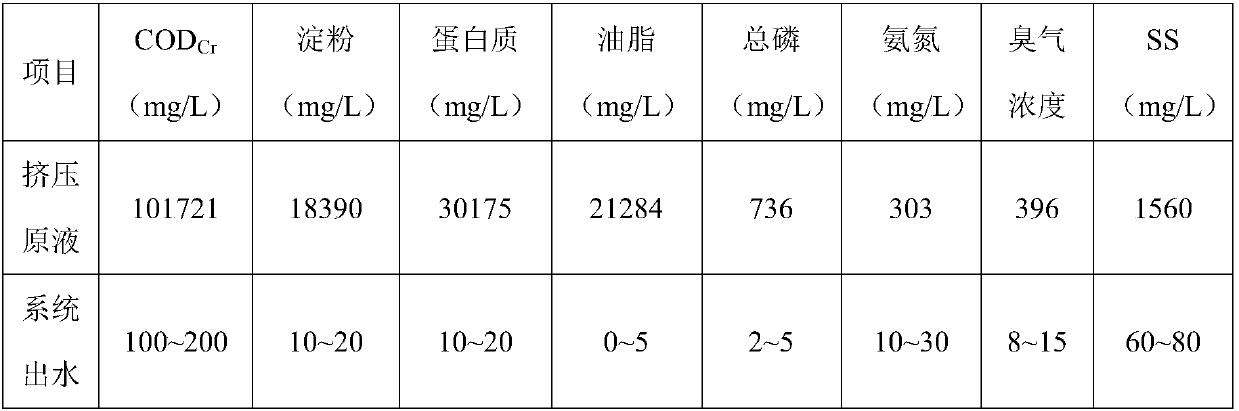

[0055] The concentration of pollutants in the garbage extrusion stock solution is too high, COD Cr The concentration is 2,500 times that of surface water Class V standard. Microbiological plate analysis of the waste extruded liquid shows that there is a very small amount of microorganisms in the liquid (about 10 3 cfu / mL) to survive, the types are messy, and there is a sour smell ( figure 2 ). The added compound microbial agent grows into dominant bacteria in the aerobic pool for 6-8 hours ( figure 2 ), inhibit the growth and reproduction of harmful bacteria, accelerate the elimination of odor, and efficiently purify water quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com