High-efficiency static electricity dust removal device based on electrification-by-friction principle of differential hairbrushs

A friction electrification and electrostatic precipitator technology, applied in the field of air purification, can solve the problems of large temperature and humidity influence, short filter life, increased filter pressure loss, etc., to improve charging durability, good filtration performance, and reduce friction frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

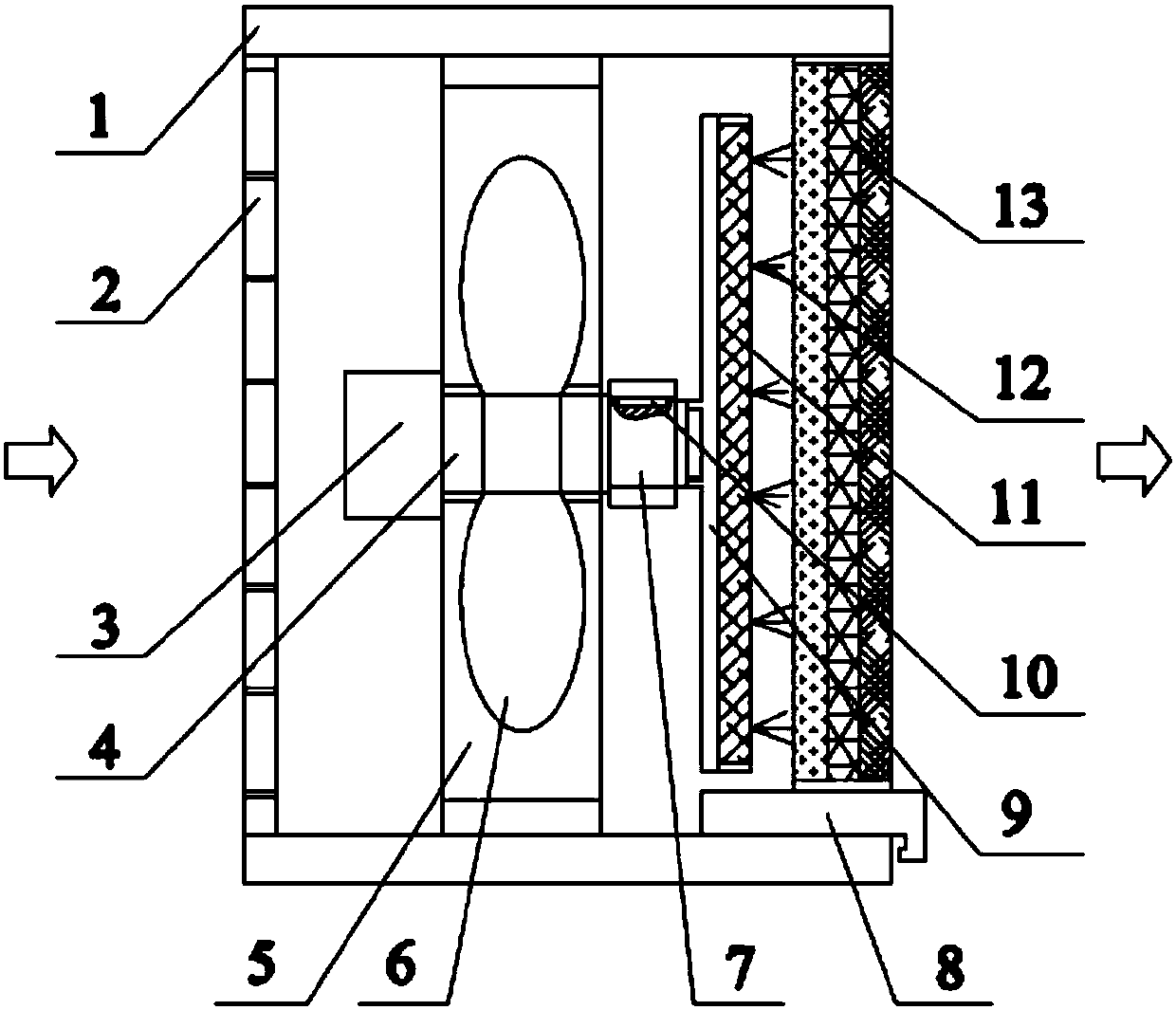

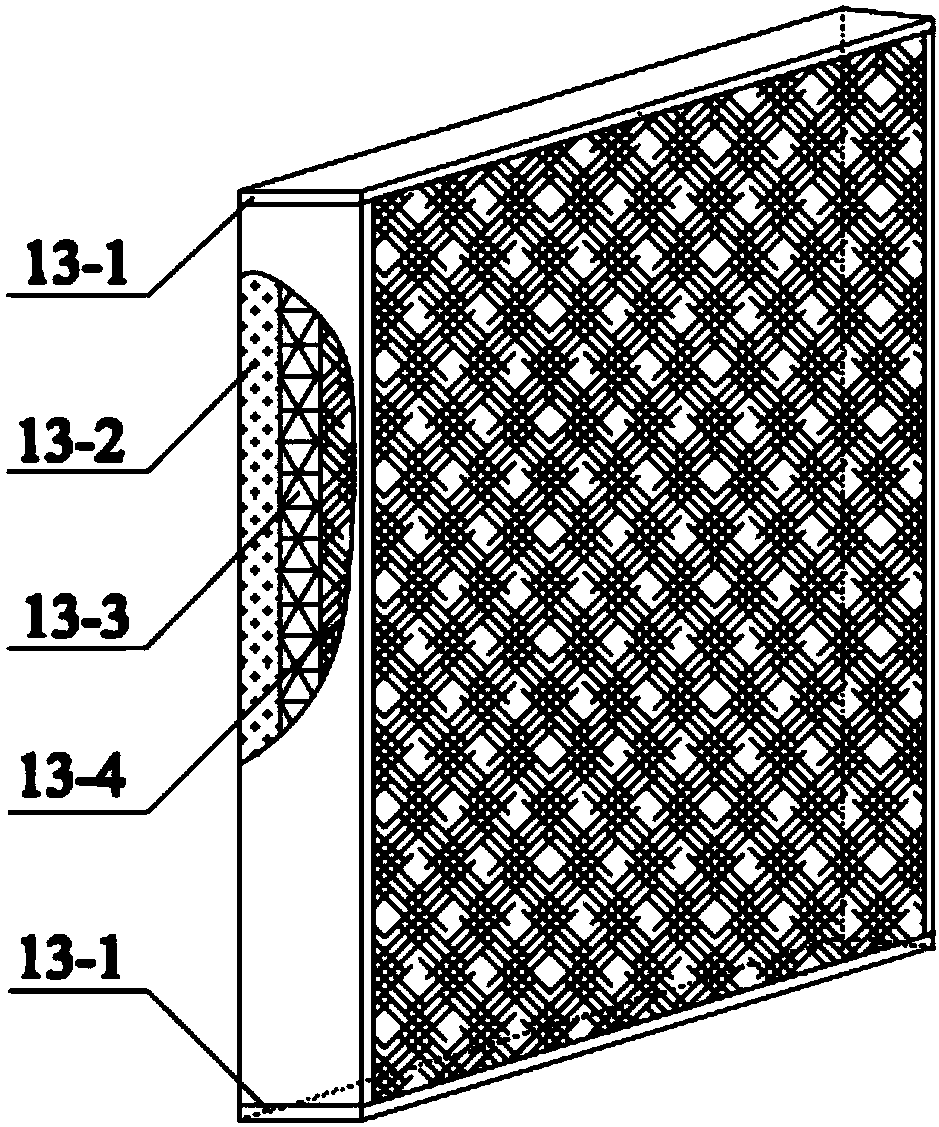

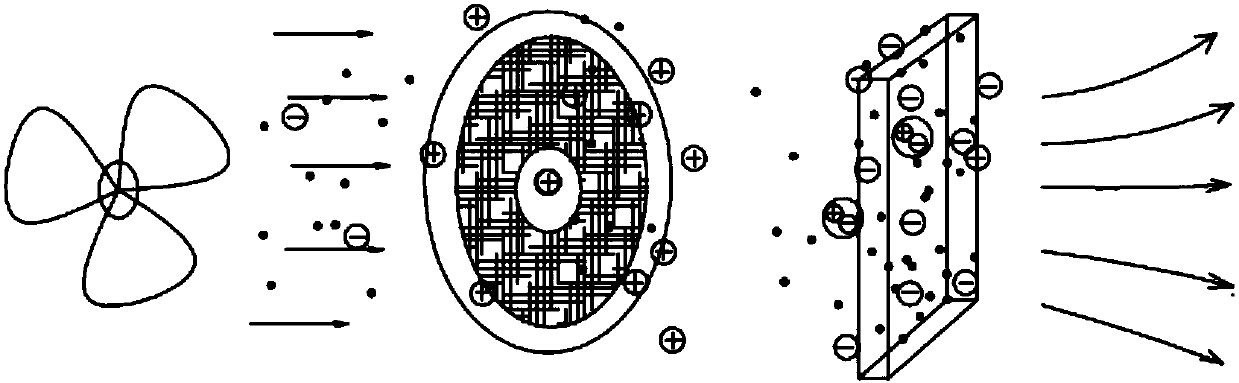

[0022] The invention is an efficient electrostatic dust removal device based on the principle of differential brush friction electrification, such as figure 1 As shown, it mainly includes: box body 1, grid plate 2, motor 3, central shaft 4, fan housing 5, fan 6, electromagnetic clutch 7, push-pull dust collection tank 8, ring metal mesh 9, flat key 10, The fiber membrane 11, the brush 12, the filter module 13, and the like. The grid plate 2 and the filter assembly 13 are respectively placed at the air inlet end and the air outlet end of the filter. The fan 6 is installed in the fan housing 5 and is in interference fit with the cabinet 1. The central shaft 4 is located in the central position, and the motor 3 is coaxially arranged with the fan 6, the annular metal mesh 9 and the electromagnetic clutch 7. The electromagnetic clutch 7 and the central shaft 4 are connected by a flat key 10. The motor 3 drives the fan 6 and the annular metal mesh 9 to rotate at the same speed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com