High temperature resistant, two component, low viscosity silicone composition

A composition and two-component technology, applied in mechanical equipment, engine components, engine sealing, etc., can solve problems such as difficult application of sealing surfaces, lack of tolerance, viscosity of curable organosiloxane compositions, etc. , to achieve the effect of good tolerance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Preparation of 1-A

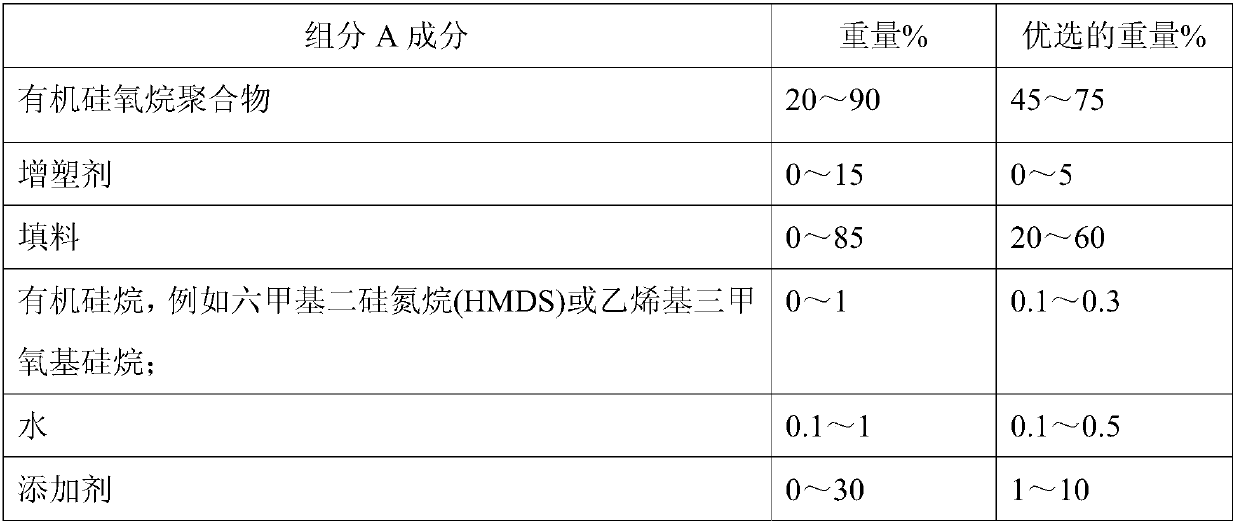

[0081] Element

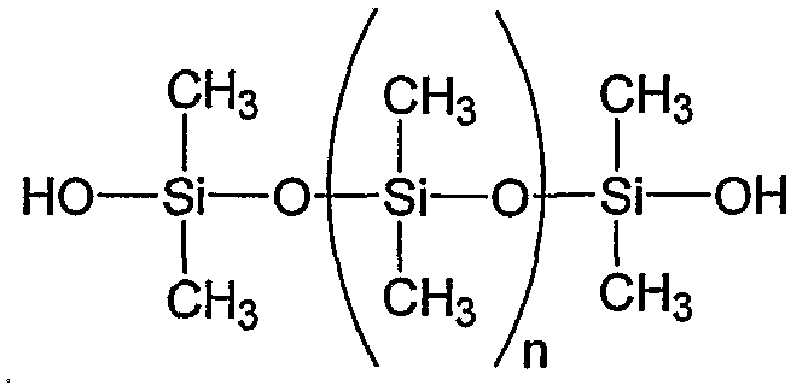

[0082] 1 Hydroxy-terminated PDMS

[0083] 2 Silbond 8000TST

[0084] 3 Zeothix 95

[0085] Example 1-A was prepared as follows. Add cristobalite powder, colorant, hexamethyldisilazane, and most of the organosiloxane polymer to the mixer. The ingredients were mixed at high speed and heated to 100°C for 30 minutes. Heat and vacuum strip (strip) for 30 minutes. Let cool to room temperature. The remaining ingredients were added and mixed under vacuum for 30 minutes while maintaining the batch temperature below 50°C. The final Part A composition has a viscosity of about 40,000-50,000 cP.

[0086] Preparation of 1-B

[0087] Element

[0088] 1 Methyl-terminated PDMS

[0089] 2 Aerosil R8200

[0090] 3 Silbond 8000TST

[0091] 4 LM400

[0092] 5 AMMOs

[0093] 6 UL 38

[0094] Example 1-B was prepared as follows. Add plasticizer, cristobalite powder and fumed silica to the mixer. Mix at high speed and he...

Embodiment 2

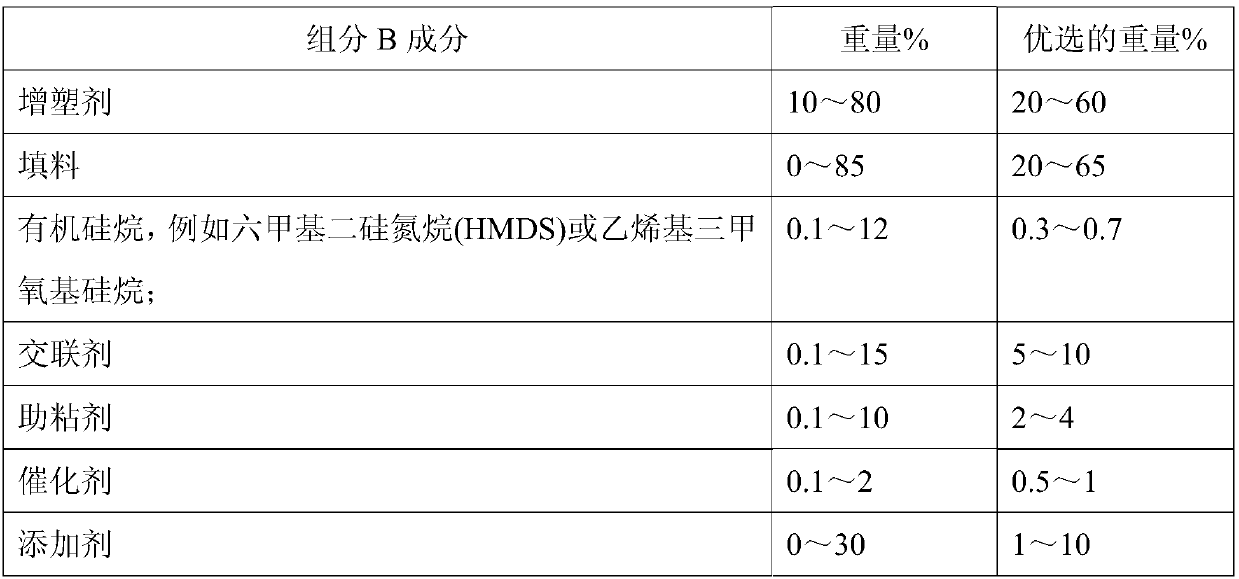

[0105] Preparation of 2-A

[0106] Element

weight%

organosiloxane polymer 1

77.4

Fumed silica, surface treated 2

15

carbon black filler

2.5

3.6

iron oxide black

1.5

[0107] 1 Hydroxy-terminated PDMS

[0108] 2 Aerosil R8200

[0109] 3 Zeothix 95

example 2-A

[0110] Example 2-A was prepared as follows. Fumed silica, iron oxide powder, colorant, hexamethyldisilazane and most of the organosiloxane polymer were added to the mixer. The ingredients were mixed at high speed and heated to 100°C for 30 minutes. Heat and vacuum strip for 30 minutes. Let cool to room temperature. The remaining ingredients were added and mixed under vacuum for 30 minutes while maintaining the batch temperature below 50°C. The final Part A composition has a viscosity of about 45,000-55,000 cP.

[0111] Preparation of 2-B

[0112] Element

[0113] 1 Methyl-terminated PDMS

[0114] 2 Aerosil R8200

[0115] 3 LM400

[0116] 4 AMMOs

[0117] 5 UL 38

[0118] Example 2-B was prepared as follows. Add plasticizer, quartz filler and fumed silica to the mixer. Mix at high speed and heat to 100°C under vacuum for 30 minutes. Let cool to room temperature. Add the oxime crosslinker and mix under vacuum for 5 minutes. Add the adhesion promoter and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com