Low-water heating/cooling device for internal-combustion engine

A cooling device, low water temperature technology, used in engine cooling, internal combustion piston engines, liquid cooling, etc., can solve problems such as corrosion of metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

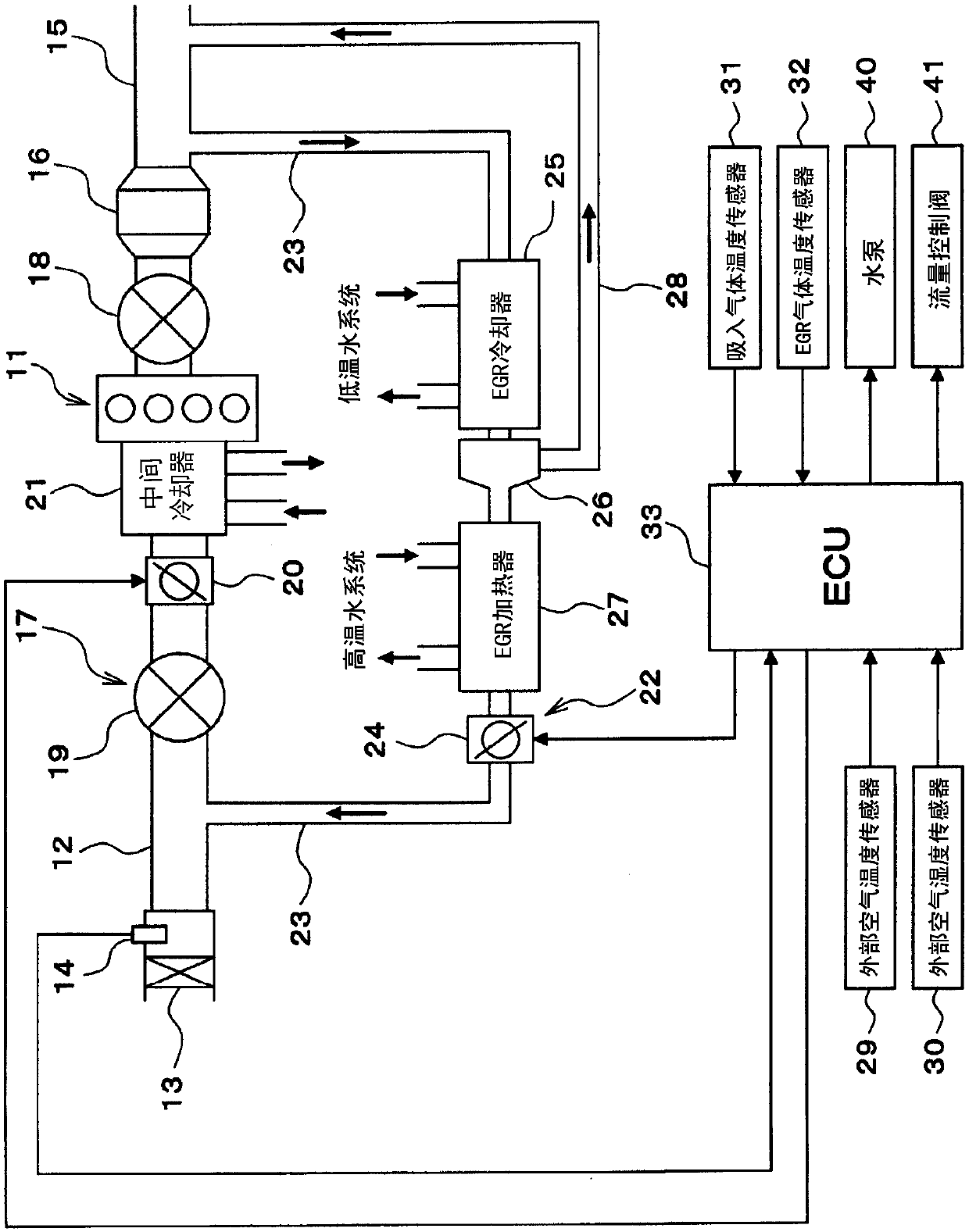

[0028] based on Figure 1 to Figure 6 Example 1 of the present disclosure will be described.

[0029] First, based on figure 1 The schematic configuration of the engine control system will be described.

[0030] An air cleaner 13 is provided at the most upstream portion of an intake pipe 12 (intake passage) of an engine 11 which is an internal combustion engine. On the downstream side of the air cleaner 13, an air flow meter 14 for detecting the amount of intake air is provided. On the other hand, the exhaust pipe 15 of the engine 11 is provided with a countermeasure against CO, HC, and NO in the exhaust gas. X etc. Catalysts 16 such as three-way catalysts for purification.

[0031] An exhaust turbine-driven supercharger 17 for supercharging intake gas is attached to the engine 11 . Here, the intake gas may be only intake air (fresh air), but may be a mixed gas of intake air and EGR gas. In the supercharger 17 , an exhaust turbine 18 is arranged on the upstream side of ...

Embodiment 2

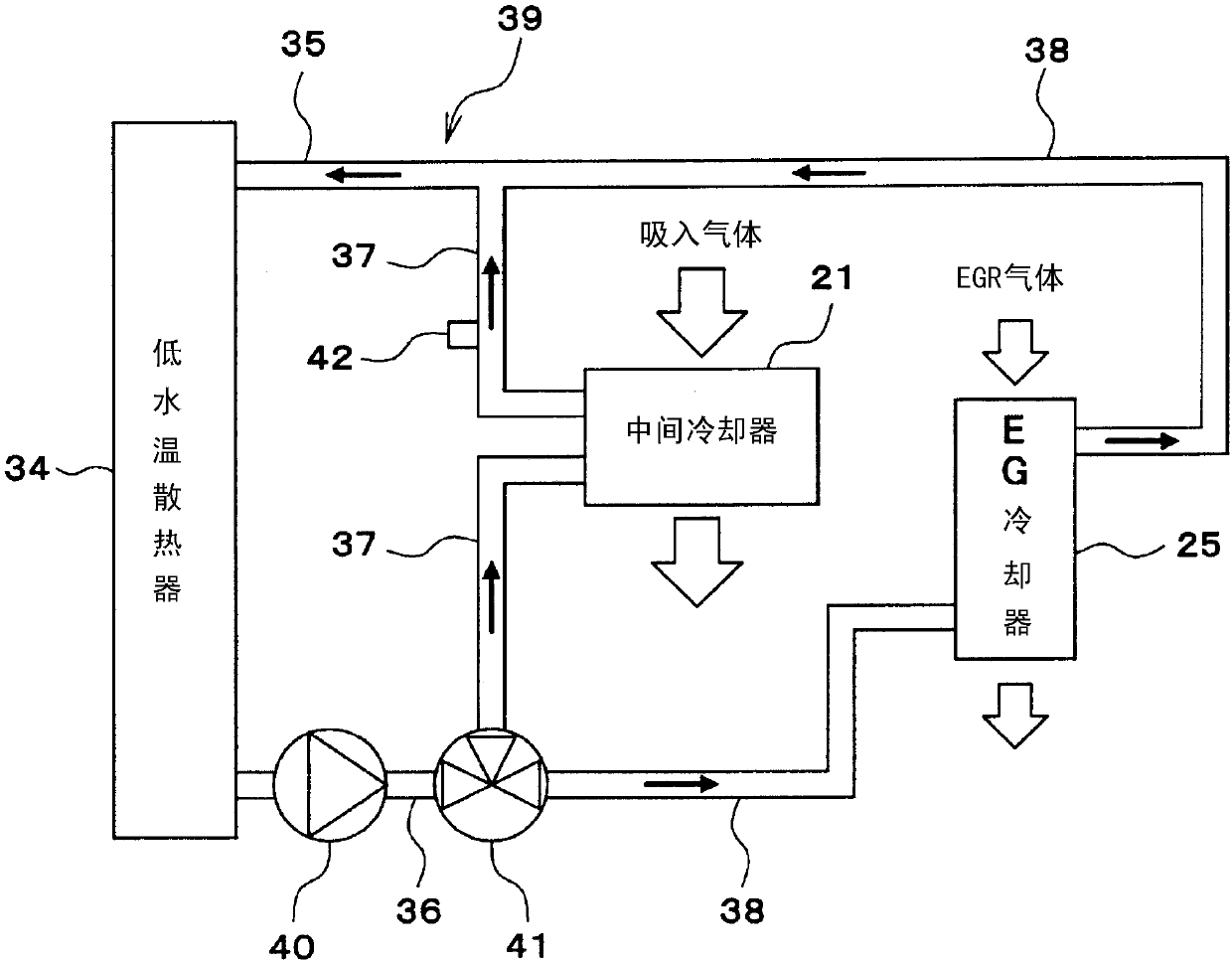

[0092] Next, use Figure 7 as well as Figure 8 Example 2 of the present disclosure will be described. Here, descriptions of parts that are actually the same as those in Embodiment 1 are omitted or simplified, and parts that are different from Embodiment 1 are mainly described.

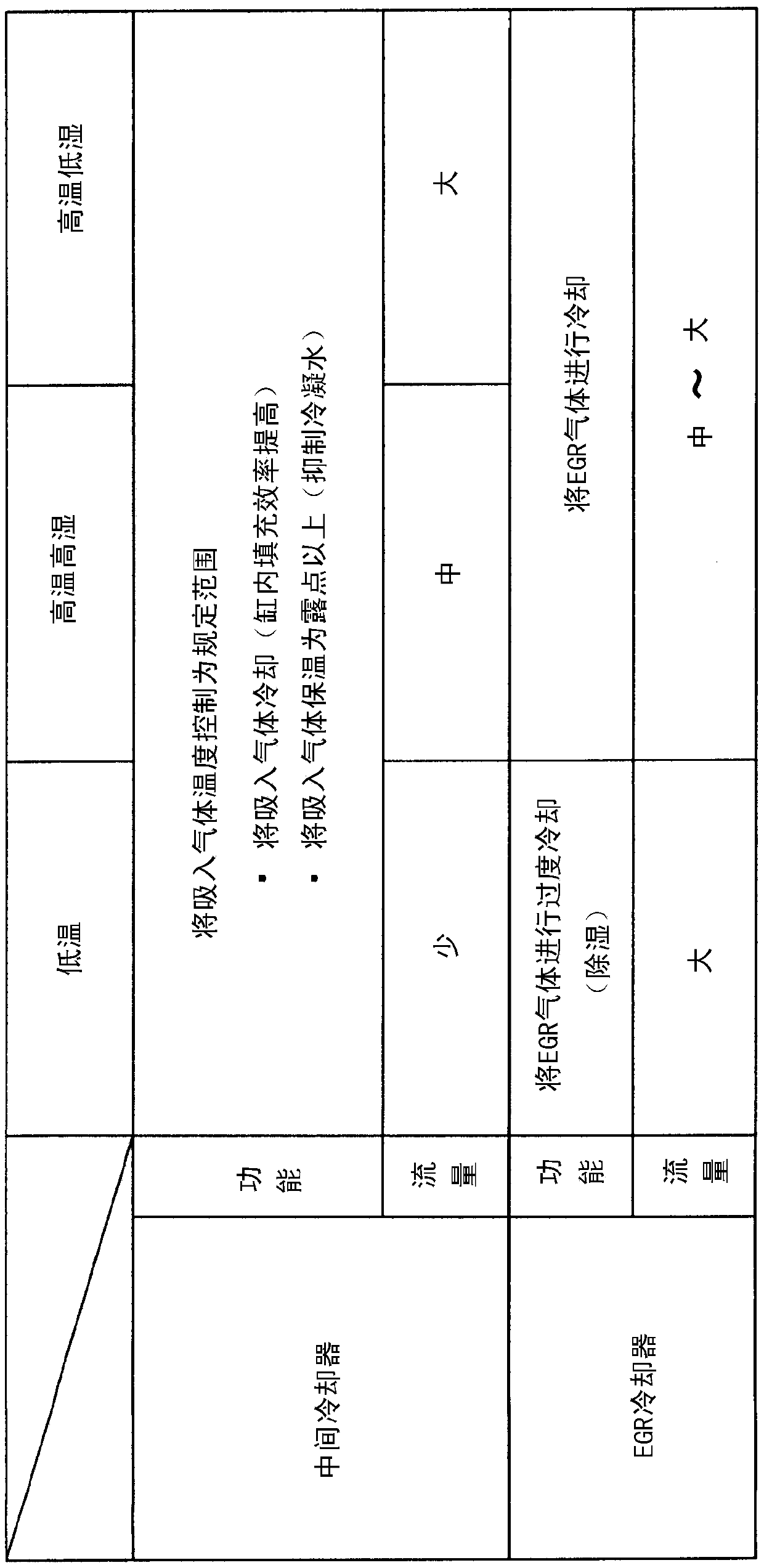

[0093] In this embodiment 2, use ECU33 to execute Figure 7 According to the flow control program, the flow control valve 41 is controlled according to the external air environment and the operating state of the engine, so that the flow ratio between the intercooler 21 and the EGR cooler 25 is changed.

[0094] exist Figure 7 In the flow rate control routine of , firstly, in 301 , the engine operating state, outside air temperature, and outside air humidity are obtained, and then proceeds to 302 , where it is determined whether the engine 11 is in stable operation.

[0095] In 302, if it is determined that the steady operation is in progress, proceed to 303, refer to Figure 8 The shown correspo...

Embodiment 3

[0102] Next, use Figure 9 as well as Figure 10 Example 3 of the present disclosure will be described. Among them, the same symbols are attached to the parts that are actually the same as those in Embodiment 1, and descriptions are omitted or simplified, and the parts that are different from Embodiment 1 will be mainly described.

[0103] In this embodiment 3, if Figure 9 As shown, the flow rate ratio of the intercooler 21 to the EGR cooler 25 is adjusted by providing a flow control valve 41 in the intercooler flow path 37 and adjusting the flow rate of the intercooler 21 by the flow control valve 41 . Alternatively, it can also be used as Figure 10 As shown, the flow rate ratio of the intercooler 21 to the EGR cooler 25 is adjusted by providing a flow control valve 41 in the EGR cooler flow path 38 and adjusting the flow rate of the EGR cooler 25 using the flow control valve 41 . In both cases, the flow rate ratio between the intercooler 21 and the EGR cooler 25 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com