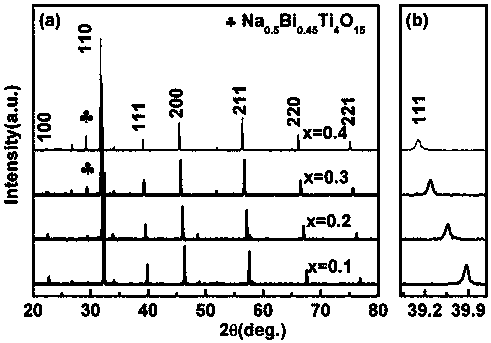

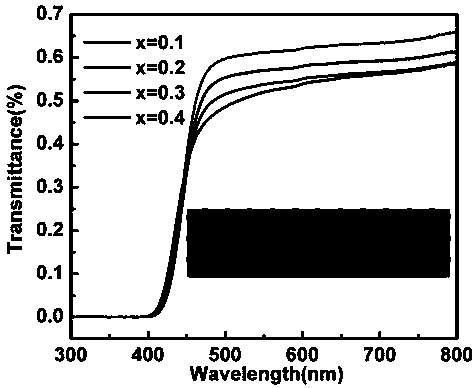

(Na0.5Bi0.5)(1-x)BaxTi(1-x)SnxO3 ceramic and preparing method thereof

A ceramic base and ceramic material technology, applied in the field of transparent high energy storage density BaxTiSnxO3 ceramic material and its preparation, can solve the limitations of ceramic breakdown strength and light transmittance, slow diffusion rate of Sn element, difficult to prepare dielectric ceramics, etc. problem, achieve the effect of improving solid solubility, low material cost, and improving breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A light-transmitting high energy storage density (Na 0.5 Bi 0.5 ) (1-x) Ba x Ti (1-x) sn x o 3 A method for preparing a ceramic material, comprising the steps of:

[0032] Step 1: Prepare pure-phase NBT and pure-phase BSN for later use. Weigh BaCO according to the molar ratio of 1:1 3 and SnO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 、Na 2 CO 3 and TiO 2 mixed to form mixture B; Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 、TiO 2 , SnO 2 The purity is above 99.0%.

[0033] Step 2: Mix the mixtures A and B with zirconium balls and deionized water respectively according to the mass ratio of 1:5:(0.8~1), 1:5:(1~1.2), and then use planetary ball mill for ball milling 18~24h, then dry at 85~100°C for 20~24h, after briquetting, put A and B in a box-type furnace respectively at 1150~1200°C for 2.5~3 hours, 820~840°C for 3~4 hours hours to form BSN powder and NBT powder respectively, and set aside;

[0034] Step 3: According to the chemic...

Embodiment 1

[0040] The present invention has light transmittance and high energy storage density (Na 0.5 Bi 0.5 ) (1-x) Ba x Ti (1-x) sn x o 3 The preparation method of ceramic material, its formula is (Na 0.5 Bi 0.5 ) (1-x) Ba x Ti (1-x) sn x o 3 ,in x =0.1.

[0041] Step 1: Prepare pure-phase NBT and pure-phase BSN for later use. Weigh BaCO according to the molar ratio of 1:1 3 and SnO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 、Na 2 CO 3 and TiO 2 mixed to form mixture B; Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 、TiO 2 , SnO 2 The purity is above 99.0%.

[0042] Step 2: Mix the mixtures A and B with zirconium balls and deionized water respectively according to the mass ratio of 1:5:1 and 1:5:1 respectively, then use a planetary ball mill for 24 hours, and then bake at 80°C After drying for 24 hours and briquetting, put A and B in a box-type furnace for 3 hours at 1200°C and 4 hours at 820°C respectively to form BSN powder and NBT powder ...

Embodiment 2

[0048] The present invention has light transmittance and high energy storage density (Na 0.5 Bi 0.5 ) (1-x) Ba x Ti (1-x) sn x o 3 The preparation method of ceramic material, its formula is (Na 0.5 Bi 0.5 ) (1-x) Ba x Ti (1-x) sn x o 3 ,in x =0.2.

[0049] Step 1: Prepare pure-phase NBT and pure-phase BSN for later use. Weigh BaCO according to the molar ratio of 1:1 3 and SnO 2 Mix to form mixture A; weigh Bi according to the molar ratio 1:1:4 2 o 3 、Na 2 CO 3 and TiO 2 mixed to form mixture B; Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 、TiO 2 , SnO 2The purity is above 99.0%.

[0050] Step 2: Mix the mixtures A and B with zirconium balls and deionized water respectively according to the mass ratio of 1:5:1 and 1:5:1 respectively, then use a planetary ball mill for 24 hours, and then bake at 80°C After drying for 24 hours and briquetting, put A and B in a box-type furnace for 3 hours at 1200°C and 4 hours at 820°C respectively to form BSN powder and NBT powder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com