Cellulose nanofiber plate and preparation method thereof

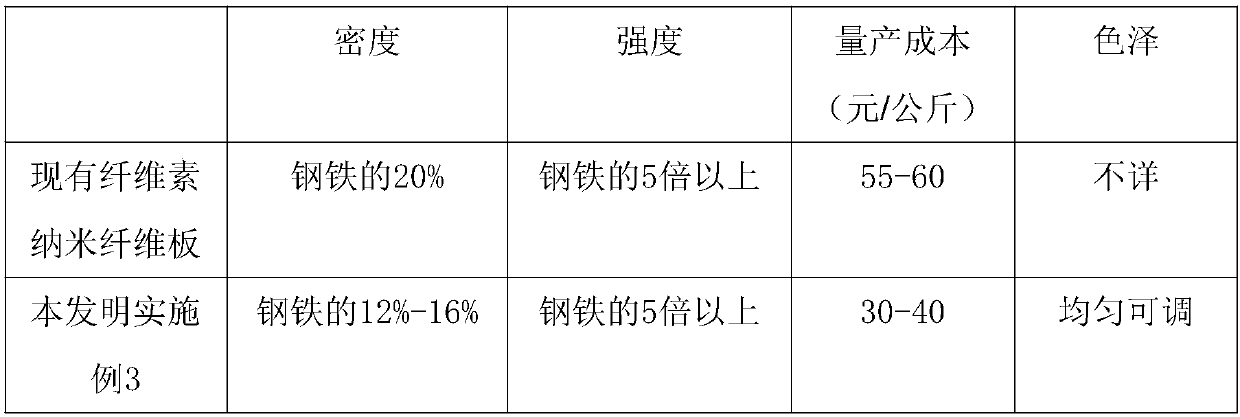

A cellulose fiber and nanofiber technology, applied in the field of cellulose nanofiber board and its preparation, can solve the problems of complex preparation process, uneven quality and high price, and achieve the effect of thick color, stable size and performance, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A cellulose nanofiber board, characterized in that the cellulose nanofiber board is made of the following five components, and the weight percentages of each component are respectively: 50% of cellulose nanofiber, 42% of ultra-high molecular weight polyethylene, Nano copper powder 5%, polyvinyl alcohol 1%, color masterbatch 2%.

[0035] The ultra-high molecular weight polyethylene is polyethylene micropowder with a molecular weight ≥ 8 million, the particle size of the ultra-high molecular weight polyethylene is ≤ 25 μm, and the specific gravity is 0.9 g / cm 3 , Water absorption <0.01%.

[0036] A preparation method of cellulose nanofiber board, comprising the following steps:

[0037]Step 1: Extraction of cellulose fibers: with the help of conventional extraction methods, the bamboo chips are extracted four times with the mixed solution of benzene, alcohol, sodium hydroxide solution, acetic acid and hydrogen peroxide, and separated, dried and dried. Get cellulose to s...

Embodiment 2

[0043] A cellulose nanofiber board, characterized in that the cellulose nanofiber board is made of the following five components, and the weight percentages of each component are respectively: 58% of cellulose nanofiber, 40% of ultra-high molecular weight polyethylene, Nano copper powder 1%, polyvinyl alcohol 0.5%, color masterbatch 0.5%.

[0044] The ultra-high molecular weight polyethylene is polyethylene micropowder with a molecular weight ≥ 8 million, the particle size of the ultra-high molecular weight polyethylene is ≤ 25 μm, and the specific gravity is 0.95 g / cm 3 , Water absorption <0.01%.

[0045] A preparation method of cellulose nanofiber board, comprising the following steps:

[0046] Step 1: Extraction of cellulose fibers: with the help of conventional extraction methods, the bamboo chips are extracted four times with the mixed solution of benzene, alcohol, sodium hydroxide solution, acetic acid and hydrogen peroxide, and separated, dried and dried. Get cellulos...

Embodiment 3

[0052] A cellulose nanofiber board, characterized in that the cellulose nanofiber board is made of the following five components, and the weight percentages of each component are respectively: 50% of cellulose nanofibers, 45% of ultra-high molecular weight polyethylene, Nano copper powder 4.899%, polyvinyl alcohol 0.1%, color masterbatch 0.001%.

[0053] The ultra-high molecular weight polyethylene is polyethylene micropowder with a molecular weight ≥ 8 million, the particle size of the ultra-high molecular weight polyethylene is ≤ 25 μm, and the specific gravity is 0.9 g / cm 3 , Water absorption <0.01%.

[0054] A preparation method of cellulose nanofiber board, comprising the following steps:

[0055] Step 1: Extraction of cellulose fibers: with the help of conventional extraction methods, the bamboo chips are extracted four times with the mixed solution of benzene, alcohol, sodium hydroxide solution, acetic acid and hydrogen peroxide, and separated, dried and dried. Get ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com