Alcohol preparation technology and device by means of continuous fermentation method

A fermentation method and process technology, which is applied in the field of continuous fermentation method to prepare alcohol to achieve the effect of maintaining vitality and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

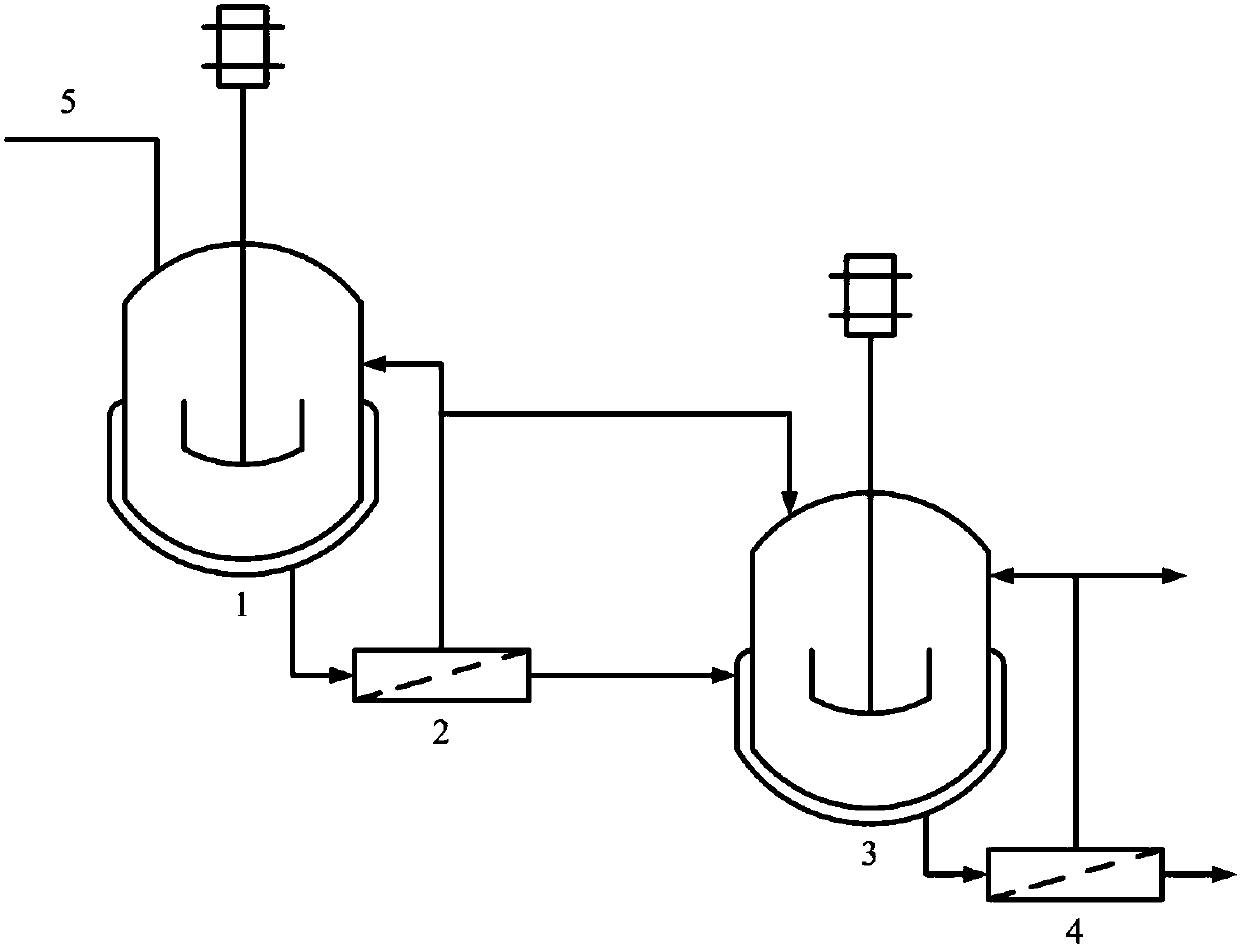

Embodiment 1

[0030] Filtrate the first ceramic membrane in the first fermenter, and obtain activated strains on the intercepted side, a part of the intercepted side feed liquid enters the second fermenter for bacterial fermentation, and the other part of the retained feed liquid returns to the first fermenter to maintain the concentration of the strain , the permeate of the first ceramic membrane is sent to the second fermentation tank as raw material; the first ceramic membrane filter adopts continuous operation mode, the material is zirconia membrane, the average pore size is 200nm, the cross-flow velocity is 4m / s, and the filtration pressure is at 0.2 Mpa, the temperature is 37°C.

[0031] The fermented liquid obtained from the fermentation in the second fermenter is sent to the ceramic membrane for filtration, and the bacterial strains that have entered the decay period are obtained on the intercepted side, and part of the intercepted side feed liquid enters the subsequent ethanol recov...

Embodiment 2

[0034]Filtrate the first ceramic membrane in the first fermenter, and obtain activated strains on the intercepted side, a part of the intercepted side feed liquid enters the second fermenter for bacterial fermentation, and the other part of the retained feed liquid returns to the first fermenter to maintain the concentration of the strain , the permeate of the first ceramic membrane is sent to the second fermentation tank as raw material; the first ceramic membrane filter adopts continuous operation mode, the material is alumina membrane, the average pore size is 200nm, the cross-flow velocity is 3m / s, and the filtration pressure is at 0.3 Mpa, the temperature is 40°C.

[0035] The fermented liquid obtained from the fermentation in the second fermenter is sent to the ceramic membrane for filtration, and the bacterial strains that have entered the decay period are obtained on the intercepted side, and part of the intercepted side feed liquid enters the subsequent ethanol recover...

Embodiment 3

[0038] Filtrate the first ceramic membrane in the first fermenter, and obtain activated strains on the intercepted side, a part of the intercepted side feed liquid enters the second fermenter for bacterial fermentation, and the other part of the retained feed liquid returns to the first fermenter to maintain the concentration of the strain , the permeate of the first ceramic membrane is sent to the second fermentation tank as raw material; the first ceramic membrane filter adopts continuous operation mode, the material is alumina membrane, the average pore size is 50nm, the cross-flow velocity is 2m / s, and the filtration pressure is at 0.4Mpa, the temperature is 30°C.

[0039] The fermented liquid obtained from the fermentation in the second fermenter is sent to the ceramic membrane for filtration, and the bacterial strains that have entered the decay period are obtained on the intercepted side, and part of the intercepted side feed liquid enters the subsequent ethanol recovery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com