Bacillus cereus producing keratinase and application thereof

A technology of Bacillus cereus and keratinase, applied in the field of microorganisms, can solve the problems that the original enzyme production cannot meet the needs of efficient transformation of livestock and poultry waste, and the enzyme production efficiency of strains is not very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Screening, purification, identification and preservation of strains

[0025] 1.1 Strain screening and purification

[0026] The mud samples were collected from the mud that had been submerged in feather residue for a long time near the sewage outlet of a food factory in Ningyang, Shandong. Weigh 1 g of sludge sample, put it into a conical flask containing 10 mL of sterilized physiological saline and glass beads, and shake it to fully mix the sludge sample with water. Take 1mL of the suspension and add it into a test tube filled with 9mL of sterilized physiological saline and mix well, this is 10 -1 Diluent. and so on to make 10 -2 ~10 -6 Solutions in several dilutions. Take 100 μL of the above-mentioned solution samples of different dilutions and apply them to a milk screening plate (10% skimmed milk powder sterilized at 116°C for 30 minutes and mix with beef extract peptone medium (beef extract 0.5%, peptone 1%, NaCl 0.5%, pH 7.5) Mix according to the ratio of 1:...

Embodiment 2

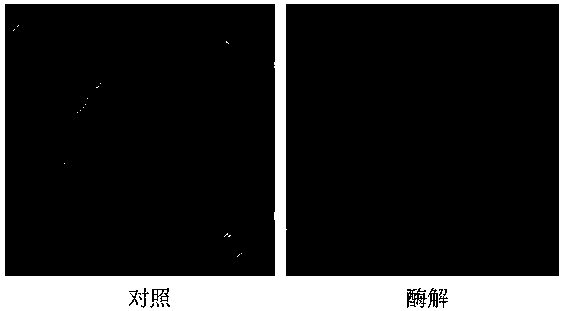

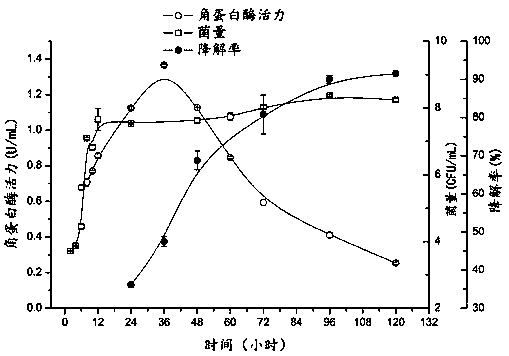

[0034] Crude Enzyme Solution Extraction and Feather Degradation

[0035] The seed liquid of B. cereus Y-15 was inserted into the optimized enzyme-producing medium according to the inoculum amount of 2%. After culturing at 30°C and 180r / min for 48 hours, the bacteria were removed by centrifugation to obtain the crude enzyme liquid. 1L of medium can obtain a total enzyme activity of 11000U of crude enzyme solution. The crude enzyme solution treats feathers at 45°C and 150r / min. After 24 hours, visual observation shows that the overall volume of the enzymatically hydrolyzed feathers becomes smaller, the amount of feathers decreases, and the solution changes from clear to cloudy. The feather structure was destroyed, the rachis curled up, most of the barbs of the feathers were degraded and disappeared, and only part of the rachis remained (attached Figure 5 ). Under the experimental conditions, the degradation rate of feather waste is 50%, and the degradation effect is remarkabl...

Embodiment 3

[0037] Optimization of Enzyme Production Conditions in B. cereus Y-15

[0038] Referring to the method of Tiwary and Gupta (Bioresource Technology, 2010, 101 (15): 6103-6110.), Feather peptone medium (Feather peptone medium, FM1) (0.5% of feather meal, 0.5% of peptone, 1% of glucose, K 2 HPO 4 0.3%, KH 2 PO 4 0.1%, pH 7.5, 1×10 5 Pa sterilization 20min). B. cereusY-15 seed solution was inserted into FM1 medium at 2% inoculum size, and cultured at 30°C and 180 r / min for 48 hours, and the enzyme activity of keratinase in the fermentation broth was determined to be 0.52 U / mL.

[0039] The enzyme production conditions of B. cereus Y-15 were optimized by comprehensive use of single factor experiment, PB design and central combination design.

[0040] 3.1 Single factor experiment

[0041] Select culture temperature (30°C, 37°C), medium pH (6.0-10.0, set a pH gradient for every 1.0), inoculum size (volume ratio) (2%, 4%, 6%, 8%), 9 Common carbon sources for cultivating bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com