Device and method for synchronously producing different kinds of coated powders by electro-deposition

An electrodeposition method and coating technology, applied in the direction of transportation and packaging, electrolysis process, electrolysis components, etc., to achieve the effect of changing fluidity and sintering performance, avoiding instability, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

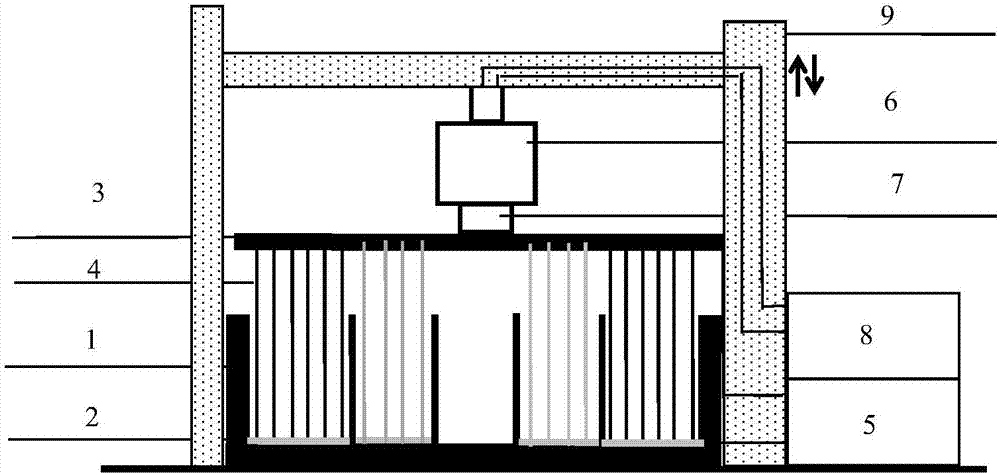

[0050] Such as figure 1 As shown, the present invention provides a device for the simultaneous production of different kinds of coated powders by electrodeposition, wherein the anode rod and the anode clamping structure are placed at 90°, and the device further includes a support, which supports The anode clamping structure drives the anode rod to make a circular motion in the electroplating tank through the motor drive shaft. The electroplating tank has a three-dimensional shape with an opening at the top, and the electroplating tank has a cylindrical shape. The inside of the electroplating tank is an annular three-dimensional structure formed by combining cylinders with different diameters, the cathode plate is a two-dimensional plane figure, and the cathode plate is placed at the bottom of the electroplating bath and is connected in a sealed manner. The anode rod is a three-dimensional shape, and the anode clamping structure is a concentric structure with different diameters,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com