Thermal-insulation and waterproof composite material

A composite material and thermal insulation layer technology, applied in the field of composite materials, thermal insulation and waterproof composite materials, can solve the problems of not being able to maintain the temperature of the tent well, increasing the thickness and weight of the fabric, reducing the comfort of wearing clothes, etc. Absorbent, waterproof layer firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

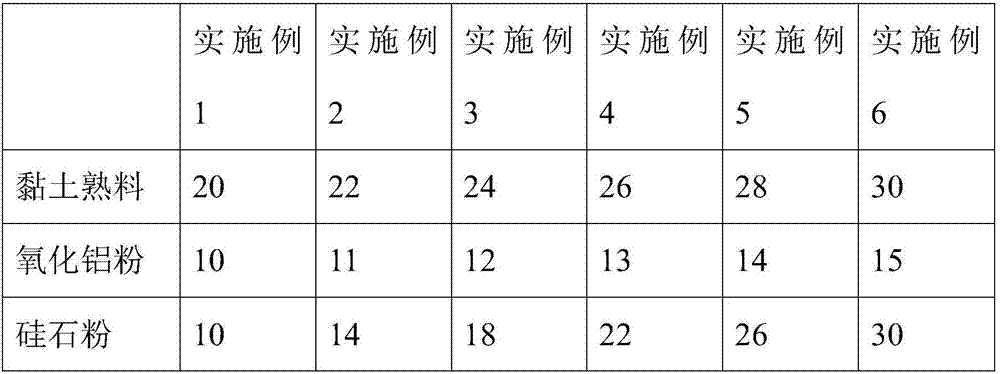

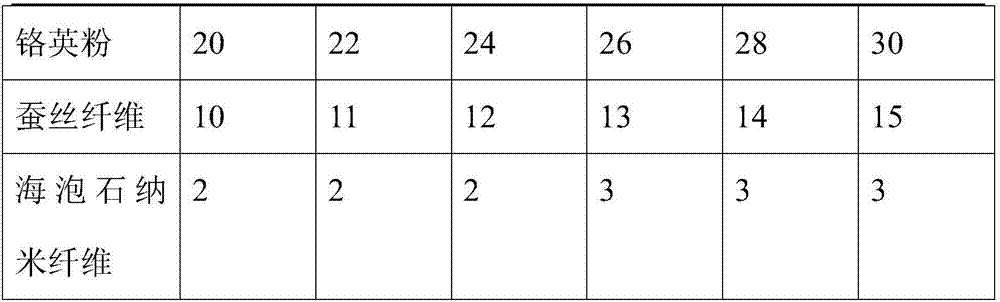

Embodiment 1

[0029] According to Example 1, the thermal insulation cotton components are melted at high temperature to form a fluid, and the filaments are spun into fibers by the spinning machine, and after the cotton is collected by the cotton collector, the thermal insulation cotton is formed; the thermal insulation cotton is repeatedly pressed 4 times to reach the required layer. number of insulation layers;

[0030] 50 parts of cationic air change yarn and 45 parts of 160D nylon air change yarn are carried out to textile processing to form Oxford cloth layer;

[0031] The polytetrafluoroethylene resin is molded, sintered, and cooled to form a blank, and then turned and calendered to form a polytetrafluoroethylene film, which is pressed with Oxford cloth while it is hot, and film composite Oxford cloth is obtained after cooling;

[0032] The nano-silica sol and PU glue are mixed and stirred evenly, and then coated on the film composite Oxford cloth by a coating machine, and dried and sh...

Embodiment 2

[0035] According to Example 2, the thermal insulation cotton components are melted at high temperature to form a fluid, and the filaments are spun into fibers by the spinning machine, and after the cotton is collected by the cotton collector, the thermal insulation cotton is formed; the thermal insulation cotton is repeatedly pressed 4 times to reach the desired layer. number of insulation layers;

[0036] 51 parts of cationic air change yarn and 46 parts of 160D nylon air change yarn are carried out to textile processing to form Oxford cloth layer;

[0037] The polytetrafluoroethylene resin is molded, sintered, and cooled to form a blank, and then turned and calendered to form a polytetrafluoroethylene film, which is pressed with Oxford cloth while it is hot, and film composite Oxford cloth is obtained after cooling;

[0038] The nano-silica sol and PU glue are mixed and stirred evenly, and then coated on the film composite Oxford cloth by a coating machine, and dried and sha...

Embodiment 3

[0041] According to Example 3, the thermal insulation cotton components are melted at high temperature to form a fluid, and the filaments are spun into fibers by the spinning machine, and after the cotton is collected by the cotton collector, the thermal insulation cotton is formed; the thermal insulation cotton is repeatedly pressed 4 times to reach the required layer. number of insulation layers;

[0042] 52 parts of cationic air change yarn and 47 parts of 160D nylon air change yarn are carried out to textile processing to form Oxford cloth layer;

[0043]The polytetrafluoroethylene resin is molded, sintered, and cooled to form a blank, and then turned and calendered to form a polytetrafluoroethylene film, which is pressed with Oxford cloth while it is hot, and film composite Oxford cloth is obtained after cooling;

[0044] The nano-silica sol and PU glue are mixed and stirred evenly, and then coated on the film composite Oxford cloth by a coating machine, and dried and sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com