Mildewproof and antibacterial environment-friendly composite paper board and preparation method thereof

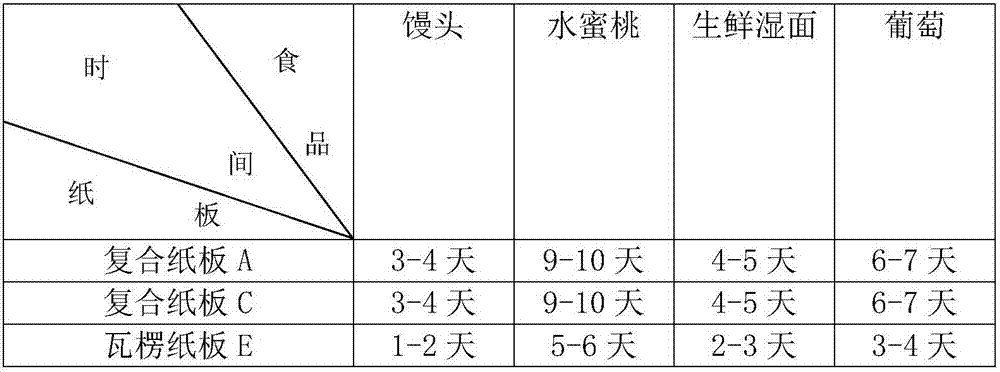

A technology of anti-mold and anti-bacteria and anti-mold and anti-bacterial agent, which is applied in the field of environmentally friendly composite cardboard and its preparation, can solve problems such as low efficiency, difficult to handle, and environmental pollution, and achieve the effects of prolonging the fresh-keeping period, preventing mold, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

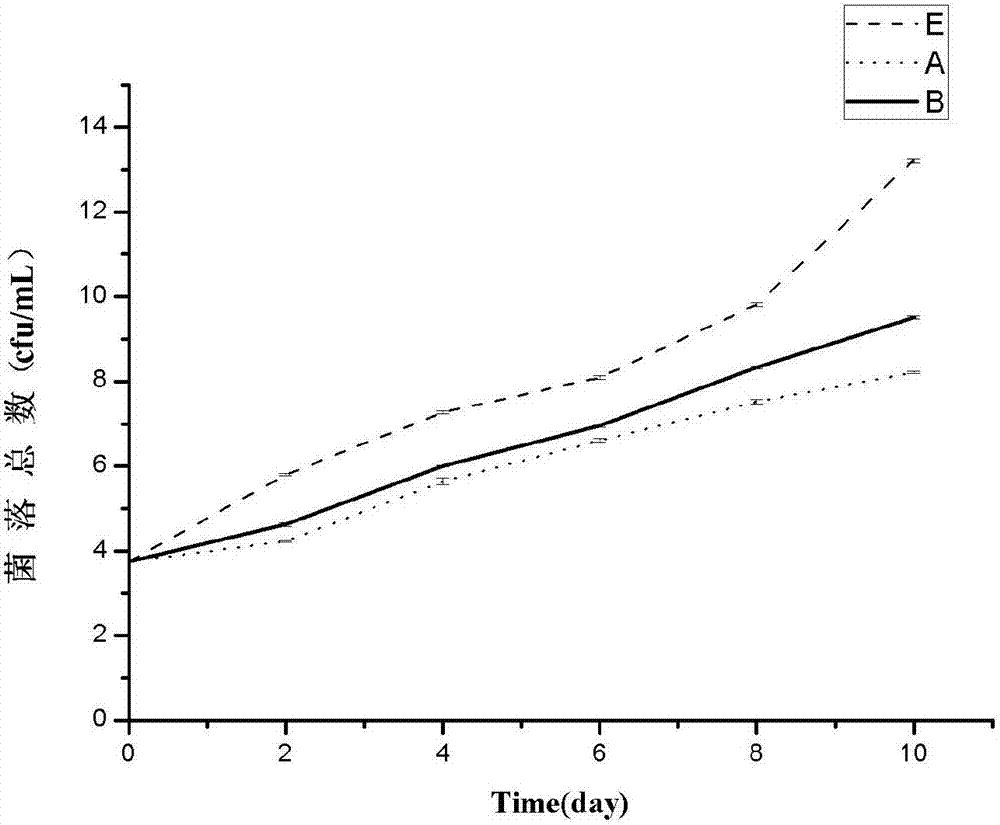

Examples

Embodiment 1

[0038] Weigh 6g of glutinous rice glue particles and 10g of coffee grounds powder in advance, add 100ml of distilled water in a beaker, add glutinous rice glue particles and coffee grounds powder at the same time, stir at a constant speed for 15 minutes, and obtain the antibacterial composite glue A required by the present invention;

[0039] Use a brush to evenly coat the antibacterial composite glue on two pieces of A4 kraft cardboard according to the volume ratio of 1:1 (each 50ml), and then glue the coated surfaces of the two pieces of kraft cardboard with antibacterial composite glue , fixed, and dried in a blast drying oven to constant weight (drying temperature 70°C, drying time 1 hour), and the anti-mildew and antibacterial environmental protection composite cardboard A of the experimental group was obtained.

Embodiment 2

[0041] Weigh 6g of glutinous rice glue particles and 10g of tea polyphenols in advance, add 100ml of distilled water into a beaker, add glutinous rice glue particles and green tea powder at the same time, stir at a constant speed for 15 minutes, and obtain the antibacterial composite glue B required by the present invention;

[0042] Use a brush to evenly coat the antibacterial composite glue on two pieces of A4 kraft cardboard according to the volume ratio of 1:1 (each 50ml), and then glue the coated surfaces of the two pieces of kraft cardboard with antibacterial composite glue , fixed, and dried in a blast drying oven to constant weight (drying temperature 70°C, drying time 1 hour), and the experimental group anti-mildew and antibacterial environmental protection composite cardboard B was obtained.

Embodiment 3

[0044] Weigh 6g of glutinous rice glue granules, 5g of coffee grounds powder and 5g of tea polyphenols in advance, add 100ml of distilled water into a beaker, add glutinous rice glue granules, coffee grounds powder and tea polyphenols at the same time, and stir at a constant speed for 15 minutes to obtain the antibacterial composite glue C;

[0045]Use a brush to evenly coat the antibacterial composite glue on two pieces of A4 kraft cardboard according to the volume ratio of 1:1 (each 50ml), and then glue the coated surfaces of the two pieces of kraft cardboard with antibacterial composite glue , fixed, and dried in a blast drying oven to constant weight (drying temperature 70°C, drying time 1 hour), to prepare the experimental group anti-mildew, antibacterial and environmentally friendly composite cardboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com