Environment-friendly fertilizer and preparation method thereof

A fertilizer and environmental protection technology, applied in the field of environmental protection fertilizer with slow release function and its preparation, can solve the problems of low effective utilization rate, large amount of waste and high cost, and achieve the promotion of the formation of soil aggregate structure, low cost, and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

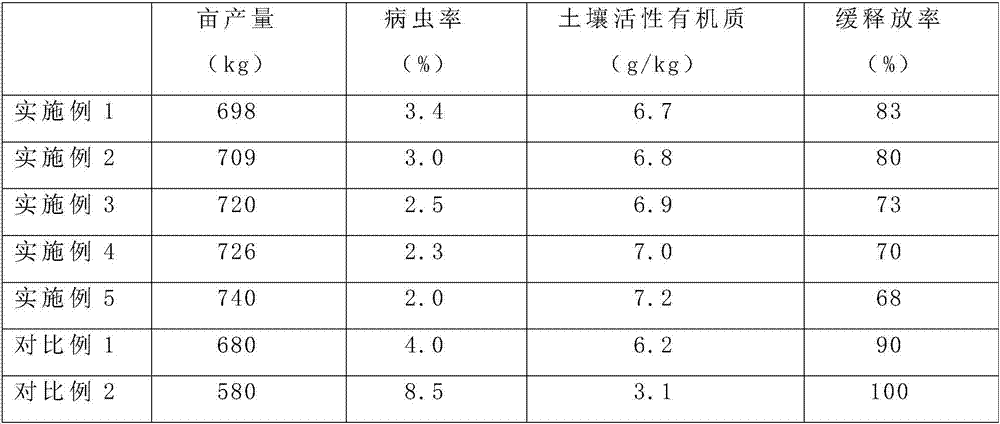

Examples

Embodiment 1

[0022] An environment-friendly fertilizer prepared by blending the following raw materials in parts by weight: 60 parts of phosphate-modified polyaspartic acid, 10 parts of potassium borate, 10 parts of ammonium phosphate, and 2 parts of polyvinyl alcohol;

[0023] Wherein, the preparation method of the phosphate-modified polyaspartic acid comprises the following steps:

[0024] 1) Phosphate-grafted polyaspartic acid: Mix 200 g of polyaspartic acid and 500 g of tris(2-chloroethyl) phosphite, stir and react at 30°C for 3 hours, and wash the product 3 times with ether , and then remove the solvent by rotary evaporation at room temperature;

[0025] 2) Ion exchange: 500 g of phosphate-grafted polyaspartic acid prepared in step 1) was added to 10000 g of sodium humate solution with a mass fraction of 20% at 50° C. and stirred for 40 hours, and then rotated at 80° C. Evaporate to remove water, and wash the product with water 4 times, and finally remove water by rotary evaporation ...

Embodiment 2

[0030] An environmentally friendly fertilizer, prepared by blending the following raw materials in parts by weight: 63 parts of phosphate-modified polyaspartic acid, 12 parts of potassium borate, 12 parts of ammonium phosphate, and 3 parts of polyvinyl alcohol;

[0031] Wherein, the preparation method of the phosphate-modified polyaspartic acid comprises the following steps:

[0032] 1) Phosphate-grafted polyaspartic acid: Mix 300 g of polyaspartic acid and 500 g of tris(2-chloroethyl) phosphite, stir and react at 33°C for 4 hours, and wash the product 4 times with ether , and then remove the solvent by rotary evaporation at room temperature;

[0033] 2) Ion exchange: 500 g of phosphate-grafted polyaspartic acid prepared in step 1) was added to 15,000 g of sodium humate solution with a mass fraction of 13% at 53° C. and stirred for 44 hours, and then rotated at 84° C. Evaporate to remove water, and wash the product with water for 5 times, and finally remove water by rotary ev...

Embodiment 3

[0038] An environmentally friendly fertilizer, prepared by blending the following raw materials in parts by weight: 65 parts of phosphate-modified polyaspartic acid, 14 parts of potassium borate, 13 parts of ammonium phosphate, and 4 parts of polyvinyl alcohol;

[0039] Wherein, the preparation method of the phosphate-modified polyaspartic acid comprises the following steps:

[0040] 1) Phosphate-grafted polyaspartic acid: Mix 350 g of polyaspartic acid and 500 g of tris(2-chloroethyl) phosphite, stir and react at 38°C for 4.5 hours, and wash the product 5 times with ether , and then remove the solvent by rotary evaporation at room temperature;

[0041] 2) Ion exchange: 500 g of phosphate-grafted polyaspartic acid prepared in step 1) was added to 20,000 g of sodium humate solution with a mass fraction of 18% at 58° C. and stirred for 47 hours, and then rotated at 86° C. Evaporate to remove water, and wash the product with water for 6 times, and finally remove water by rotary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com